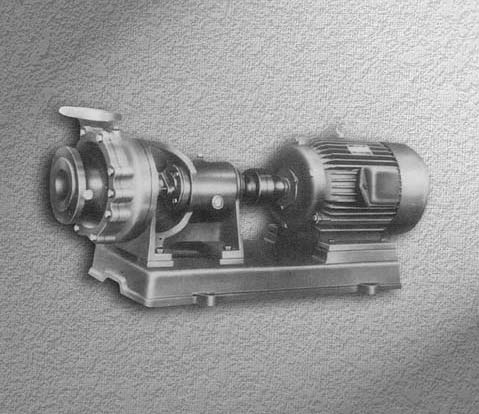

N type condensate water pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Purpose and feature

Compared with the common water pumps, model N condensing pump features a higher suction lift and is used mainly for transporting the condensed water in the condenser in a thermal power plant and also for other cases similar to medium and condensed water, as one of the crucial equipments in a thermal power plant.

2.Range of use

Medium temperature: 100N130, 150N110 can be used for transporting the liquid of a temperature less than 120 and the others for that less than 80 .

Range of flow: 12~120(m³/h)

Range of head: 38~135(m)

Medium condition: condensed water or other similar liquids.

3.About the model

The pump model is drawn up according to the size and the performance.

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- For the first time, the pump and motor were placed on the base and not fastened (Cu Zhaozheng);Second times, the pump and motor have been tightened, the inlet and outlet flange bolts are not fastened;Third times, the pump runs 24 hours later.

- Q: Troubleshooting of diaphragm pump

- The troubleshooting guide for diaphragm pumps, when encountered in one or more of the following situations, this information can be used as a guide to help you develop maintenance measures.As shown below, some of the abnormal operating conditions described in this guide are: A) fast circulation / low flow B) no cycle / slow cycle / irregular cycle C) leakage D) noise E) component rupture

- Q: Water pump can not be pumped out, how to maintain water?

- Severe vibration of water pumpIt is possible that the rotor is unbalanced, or the coupling is not good, the bearing is worn and bent, and some parts may be loosened and broken. They can be adjusted, repaired, strengthened or replaced separately.

- Q: I would like to ask, constant pressure pump set pressure 20Mpa, the actual load is 15Mpa, then the constant pressure pump outlet pressure? If it is 20Mpa, then where is the loss of 5Mpa? If 15Mpa, the constant pressure pump 20Mpa how to understand? In addition, the constant pressure pump pressure is defined when the flow began to reduce the point, or a sharp drop in flow after the point?

- 15MPa. 20MPa means that if you enter the 20MPa, the variable mechanism will work, and the flow at this time automatically matches the load. 20MPa used to supply the fuel by maximum displacement.

- Q: Double floor sewage pump circuit diagram of a small problem

- Q 2, SA and SS are select switches, and different positions indicate the same difference between the two nodes. SA hits the left position 13, 14 to connect, hits to the right position 21, 22 to connect. SS hit the middle position, 5 and 6 turn on, 7 and 8 turn on; hit the right position; 1 and 2 turn on; 11 and 12 turn on; hit the left seat; 9 and 10 turn on; 3, 4 turn on.

- Q: How many kilograms of water pump are there in the automatic washing machine on the market?

- Longer service life. Automatic switch water pump, car wash automatically open and stop, easy to operate, not easy to bad, repair rate is low!!!

- Q: What is the pump delivery? What's the difference between years and years?

- 1) integer integer: ~ batch. Sell ~.2) buy in bulk: ~ goods. Sell now.The exchange is, according to the duration of the contract delivery insurance premium, payment is generally in common, 5 years of insurance you every year that time, continuous call five years; general single sex 5 years or even 10 years of premium.Furthermore, the insurance premium is good or good pay period, if a single rate from the point of view, to make cheaper than single period, but considering the one-time payment of the interest cost of funds and the opportunity cost, there is no difference. While the single cross ratio advantage is mainly reflected in its flexibility. First of all, additional premium may be added to the premium. At present, additional risks can only be covered if the main risks and principal risks are covered during the payment period. The single way to buy insurance, even in the primary insurance protection period will no longer be able to purchase additional insurance new; secondly, to pay the premium can enjoy a premium waiver. If the insured in full payment period has not yet had the danger, not pay part of the premium would be exempt from the Qing dynasty. For child insurance, the premium waiver is more advantageous. If parents unfortunate accidents or illness, resulting in death or one or two, three disabled or suffering from severe illness, the insurance company will be exempted after the premium, the insurance contract shall continue to be valid; finally, to pay the premium or additional premium amount can be changed. The policy holder may adjust his insurance plan according to the change in his economic strength. In contrast, single premium has the advantage of a one-time payment more convenient.

- Q: What should be used to pay attention to the use of mechanical pumps?

- Overall: large pump should first do a good job of the foundation, to find a good whole, fixed, and motor, pump should be added good oil, the first test of the motor, and then conjoined test

- Q: If the calculation of the required pump flow is 45, lift 110, and the actual pump flow 100, head 125, what will happen in operation? Can I use it properly?

- Centrifugal pumps are too big to measure.There is a reason why the centrifugal pump does not measure up:The pump inlet pipe blockage, leakage.The pump inlet pressure is too low.

- Q: Why can't the centrifugal pump pump the vacuum?

- Condition:The pump shell must be filled with liquid under certain installation height and running without leakage.What is the phenomenon of centrifugal pump? What harm does it have? How to eliminate?)

Send your message to us

N type condensate water pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches