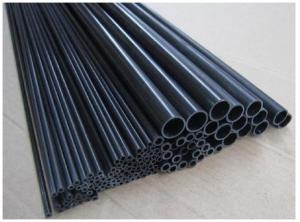

Black Delrin Tube

Black Delrin Tube Related Searches

Dip Tubes Iron Tube Iron Tubes Transparent Rubber Tube Poly Tube Netting Dicl Pipe Air Intake Tubes Structure Pipe Clear Mailing Tubes Clear Tape Dispenser Iso Metric Thread Single Basin Taps Copper Tape Uhmw Tape Pink Hockey TapeBlack Delrin Tube Supplier & Manufacturer from China

Black Delrin Tube is a type of engineering plastic tubing known for its excellent mechanical properties, chemical resistance, and low friction characteristics. This high-performance material is widely used in various industries due to its durability and versatility. Delrin tubes can be found in applications such as precision machinery, automotive components, and electronic device housings, where their resistance to wear and ability to maintain dimensional stability is highly valued.In terms of usage scenarios, Black Delrin Tube is particularly well-suited for environments where resistance to chemicals, moisture, and temperature fluctuations is crucial. Its low coefficient of friction makes it an ideal choice for applications requiring smooth movement, such as in linear bearings or mechanical linkages. Additionally, its self-lubricating properties reduce the need for additional lubricants, which can be beneficial in situations where maintaining cleanliness is important.

Okorder.com stands out as a reliable wholesale supplier of Black Delrin Tube, boasting a substantial inventory that caters to the diverse needs of various industries. Their extensive range ensures that customers can find the specific Delrin tube dimensions and properties required for their particular application. With a commitment to quality and customer satisfaction, Okorder.com is a trusted source for businesses looking to incorporate Black Delrin Tube into their product offerings or manufacturing processes.

Hot Products