Smooth Aluminum Sheets - 5083 Aluminium Sheet and Aluminium Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t

- Supply Capability:

- 9000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

aluminium sheet and aluminum plate can be used in different fields, such as construction, decoration, etc.

the grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

Normally we will export to our goods to all over the world, since we have a good reputation in the field of aluminum material, etc.

please feel free to send us inquiries whenever you are interested in it later.

2. Main features of the product

a.Competitive price

b. Frist-Class Service.

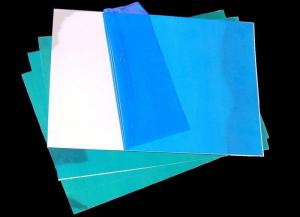

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

what is your mainly product?

---Normally it is aluminium sheet, aluminum coil,checkered sheet, mirror finish aluminum sheet, aluminum color coated coil, aluminum color coated embossed foil, cold rolled aluminium casting coil, hot rolled aluminum casting coil, etc.

what is your MOQ?

----Normally it is around 5 tons/each size.

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- Chemical transfer piping cannot rely on 101 aluminum sheets as they are unsuitable. The reactivity and corrosion propensity of aluminum make it generally unfit for handling specific chemicals. Industries like aerospace or construction prefer aluminum due to its lightweight nature and excellent thermal conductivity. However, for chemical transfer piping, it is wiser to opt for materials that possess corrosion resistance and can endure the specific chemicals being transported. Stainless steel, PVC, or high-density polyethylene (HDPE) are recommended alternatives.

- Q: Can aluminum sheets be powder-coated?

- Yes, aluminum sheets can be powder-coated. Powder coating is a process in which a dry, powdered paint is applied electrostatically to a surface and then cured under heat to create a durable and attractive finish. Aluminum is a suitable material for powder coating due to its lightweight, corrosion-resistant properties. The powder coating adheres to the aluminum surface and forms a protective layer that enhances the sheet's appearance and provides long-lasting protection against wear and tear.

- Q: Can the aluminum sheets be used for manufacturing automotive wheels?

- Yes, aluminum sheets can be used for manufacturing automotive wheels. Aluminum is a lightweight and durable material that is commonly used in the production of wheels due to its strength-to-weight ratio and corrosion resistance.

- Q: How do aluminum sheets compare to other metals in terms of strength?

- Aluminum sheets generally have lower strength compared to other metals. While aluminum is lightweight and has excellent corrosion resistance, it is not as strong as metals such as steel or titanium. Aluminum has a lower tensile strength and yield strength compared to these metals, making it more susceptible to deformation and failure under heavy loads. However, aluminum can be alloyed with other elements to improve its strength, and specific aluminum alloys can rival or even surpass the strength of some other metals. Additionally, aluminum's strength-to-weight ratio is one of its main advantages, making it a preferred choice in many industries where weight reduction is crucial, such as aerospace and automotive. Overall, while aluminum may not be the strongest metal in absolute terms, it offers a balance of strength, lightweight properties, and corrosion resistance that makes it a versatile material in various applications.

- Q: Can aluminum sheets be used for reflective surfaces?

- Yes, aluminum sheets can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it an excellent material for creating reflective surfaces. Due to its smooth and highly polished finish, aluminum sheets can effectively reflect light, heat, and other forms of radiation. This property makes them suitable for a wide range of applications, including solar panels, mirrors, lamp reflectors, and reflective insulation. The use of aluminum sheets as reflective surfaces is advantageous due to their durability, lightweight nature, and resistance to corrosion.

- Q: Can aluminum sheet be used for packaging applications?

- Certainly! Packaging applications can definitely make use of aluminum sheet. The packaging industry widely employs aluminum due to its exceptional qualities. Its lightweight nature, strength, durability, and ability to be molded make it perfect for packaging diverse products. Aluminum sheets can be easily shaped into different forms and sizes, offering tailored packaging solutions. Moreover, aluminum boasts excellent barrier properties, guarding against moisture, gases, and light, which helps maintain the freshness and quality of packaged goods. Additionally, aluminum is non-toxic and can be effortlessly recycled, making it an environmentally friendly choice for packaging applications. In conclusion, aluminum sheet is a versatile and dependable material for packaging various items, such as food, beverages, pharmaceuticals, cosmetics, and more.

- Q: Im wondering what type of clutch would be better for my fox body mustang. A aluminum or steal. And why

- aluminum if you are drag racing ( have to learn to feather the clutch a bit) STEEL on the street( easier to keep the fire lit for mere mortals ) course you can use aluminum on the street--most people cant, because you have to be easy with the clutch-but it gives you an excuse why people cant borrow your car

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: Do 101 aluminum sheets require any special maintenance or care?

- Maintenance or care is not necessary for 101 aluminum sheets. This material is durable and resistant to corrosion, allowing it to endure different environmental conditions without degradation. Nevertheless, to guarantee their longevity and optimal performance, it is suggested to regularly wipe them with a soft cloth or sponge to keep them free of dirt or debris. It is also advisable to avoid using abrasive or harsh cleaning agents in order to prevent potential harm to the aluminum sheets. In summary, with minimal attention and care, 101 aluminum sheets can retain their quality and appearance for an extended duration.

- Q: Iron is extracted from iron oxide by displacement with carbon.But aluminum is not extracted from aluminium oxide using displacement by carbon. Suggest a reason for this.

- Well, de facto because the heat of formation of aluminum oxide is so much greater than the heat of formation of iron oxide. If you're looking for something more mechanistic, find Al and Fe in the periodic table. Al and Fe are in different rows, and Fe is larger than Al, so although Al+3 and Fe+3 have the same charge, oxygen bonds less strongly to Fe+3 than to Al+3 because it's further away from the nucleus of Fe. Al+3 has no outer shell electrons at all; 3s, 3p, and 3d subshells are all empty. It's effectively a charged sphere with nothing to interfere with bonding. Fe+3 (as in hematite, Fe2O3) is larger, has filled 3s and 3p subshells, and a half-filled 3d subshell. That 3d electron density projects pretty far out into space, holding oxygen at arms length. Aluminum has no electron density in 3d orbitals, so oxygen can tuck in nice and tight and get a good grip. Any of these hit the mark? I don't know what background you're bringing to this question.

Send your message to us

Smooth Aluminum Sheets - 5083 Aluminium Sheet and Aluminium Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t

- Supply Capability:

- 9000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords