1100-h124 Aluminum Sheets Sds - Aluminium Sheet and Slab

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

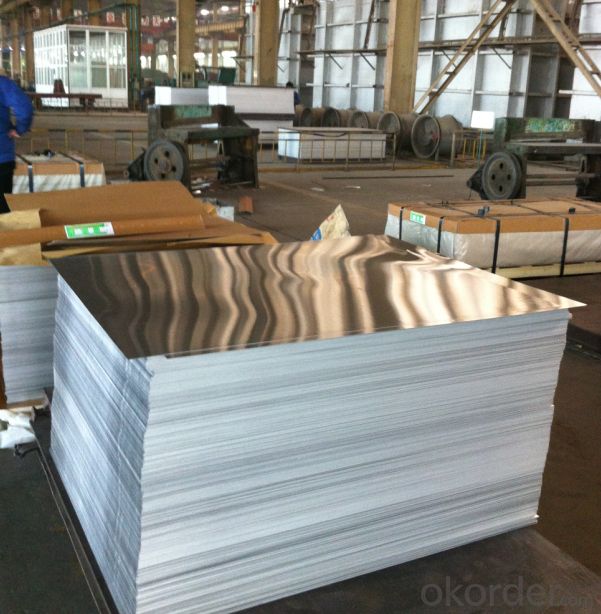

3. Image.

4. Product detailed sizes:

1219mm*2438mm,1220mm*2440mm,etc.

5. FAQ:

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

- Q: What is the density of the 2A12 aluminum plate?

- 2.75 density. Shenzhen dexincheng metal plate is sold. Specifications are all complete.

- Q: What are the different methods of forming aluminum sheets?

- There are several methods of forming aluminum sheets, each with its own advantages and applications. Here are some of the different methods: 1. Rolling: Rolling is the most common method used to form aluminum sheets. In this process, a large aluminum ingot is passed through a series of rolling mills, which gradually reduce its thickness and increase its length. The ingot is rolled multiple times until the desired thickness is achieved. Rolling can produce aluminum sheets of various thicknesses and widths, making it versatile for different applications. 2. Extrusion: Extrusion is another method used to form aluminum sheets, especially for complex cross-sectional profiles. In this process, a heated aluminum billet is forced through a shaped die, resulting in a continuous length of aluminum with the desired shape. Extrusion allows for the creation of intricate designs and is often used in the production of structural components and frames. 3. Casting: Casting is a method used to form aluminum sheets with a specific shape or pattern. In this process, molten aluminum is poured into a mold and allowed to cool and solidify. The mold can be made of various materials, such as steel or sand, depending on the complexity of the desired shape. Casting is commonly used for decorative purposes and in the production of architectural panels. 4. Stretch forming: Stretch forming is a specialized method used to form aluminum sheets into curved or contoured shapes. In this process, the sheet is clamped at its edges and stretched over a form, using hydraulic or mechanical forces. As the sheet is stretched, it conforms to the shape of the form, resulting in a curved or contoured sheet. Stretch forming is commonly used in the aerospace and automotive industries for components such as fuselage sections and car body panels. 5. Pressing: Pressing, also known as stamping or punching, is a method used to form aluminum sheets into specific shapes or patterns. In this process, the sheet is placed between a die and a punch, and pressure is applied to deform the sheet. The die and punch can have various designs and can create shapes ranging from simple cutouts to intricate patterns. Pressing is commonly used in the manufacturing of automotive parts, appliances, and electronic enclosures. These are just a few of the different methods of forming aluminum sheets. Each method offers unique advantages and is chosen based on the specific requirements of the desired shape, thickness, and application of the aluminum sheet.

- Q: I have an aluminum block engine in my wakeboard boat which is built for the lakes, now i live on salt water and was wondering the effect saltwater would have on the engine block as water goes through to cool it.

- Salt okorder /

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Yes, aluminum sheets can indeed be an alternative to plastic in certain applications. Aluminum is a highly versatile and sustainable material that offers several advantages over plastic, such as being more durable, resistant to UV rays, and having a longer lifespan. Additionally, aluminum is recyclable and can be reused indefinitely, making it a more environmentally friendly choice. However, the suitability of aluminum sheets as an alternative to plastic would depend on the specific application and requirements.

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that offers several advantages for industrial shelving applications. It is resistant to corrosion, which makes it suitable for environments that are exposed to moisture or harsh chemicals. Aluminum's strength-to-weight ratio is also advantageous, as it allows for the construction of sturdy shelves that can hold heavy loads while remaining relatively lightweight. Additionally, aluminum is easy to maintain, as it does not require painting or sealing like other metals. Overall, aluminum sheets are a practical choice for industrial shelving due to their durability, corrosion resistance, and lightweight properties.

- Q: When water continually sprays on the aluminum sheet, how to avoid corrosion of aluminum sheet and keep its water resistance?

- Don’t worry about it, after aluminum contacts water or air, a layer of oxide film will generate on its surface to separate aluminum from the water or air and protect it, so it won’t be erosive.

- Q: Are 101 aluminum sheets suitable for radiator manufacturing?

- Indeed, 101 aluminum sheets prove to be fitting for the production of radiators. This particular aluminum alloy, known as 101 aluminum, boasts a pure composition that lends itself to exceptional thermal conductivity, making it a prime choice for radiator utilization. Moreover, its remarkable resistance to corrosion proves pivotal in radiator applications that frequently entail contact with water and other fluids. Furthermore, the lightweight nature and ease of manipulation of 101 aluminum sheets facilitate efficient processes for radiator manufacturing. In summary, the desired properties and characteristics essential for the creation of radiators are duly satisfied by 101 aluminum sheets.

- Q: The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

Send your message to us

1100-h124 Aluminum Sheets Sds - Aluminium Sheet and Slab

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords