Aluminum Oxide Sanding Sheets for Aluminum Alloy Sheet 5083 Shipbuilding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Alloy Sheet 5083 for Shipbuilding Description:

5000 series aluminum alloy is a common aluminum alloy series, the main alloy elements are magnesium, the content of magnesium is 3-5%.It's non-Heat treatable aluminum alloy with good corrosion resistance, good machinability, good electric arc welding performance,beautiful surface after anodic treatment.Commonly used in aviation,shipping field,also extensive used in the conventional industry,such as cars,planes,welding pieces,Metro and light rail,need strict fireproof pressure vessel,such as liquid tankers,refrigerated trucks, refrigerated container,refrigeration equipment,television tower,drilling equipment,transportation equipment,missile parts,armor,etc.

2.Main Features of Aluminum Alloy Sheet 5083 for Shipbuilding:

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

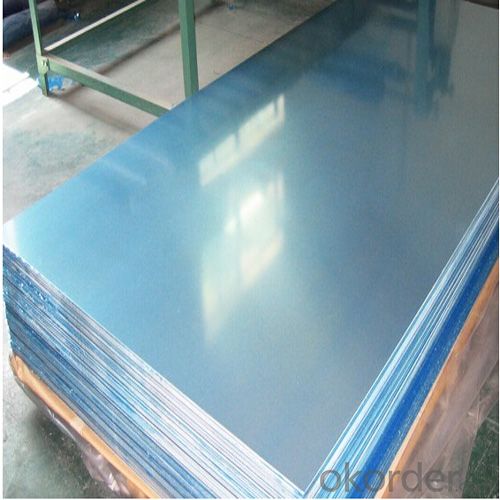

3. Aluminum Alloy Sheet 5083 for Shipbuilding Images:

4. Aluminum Alloy Sheet 5083 for Shipbuilding Specification:

roduct | aluminum plates 5052 |

Material | 5052 |

Temper | H24 |

Dimension | 4.0mm*1500mm*3000mm |

Alloy or not | non-alloy |

Surface | mill finish,no stains,without a scratch or a graze,without rough selvedge |

Property | anti-corrosion,heat resistant,good plasticity |

Technical Standard | GB/T 3880-2006 |

Tensile strength | 120~145 MPa |

Elongation | ≥6% |

Application | storage device,decoration,pressure essels,construction,electrical equipment,etc |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring applications. They are known for their durability, resistance to corrosion, and ease of maintenance, making them suitable for various environments. Aluminum flooring is often used in commercial, industrial, and residential settings due to its strength and lightweight nature. It can be found in applications such as walkways, ramps, and as a covering for platforms. However, it's important to note that aluminum may not be the best choice for all flooring needs, especially where thermal insulation or a softer, warmer feel is desired.</p>

- Q: This question asks about the impact of aluminum sheets on the quality of air inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality in a building. They are inert materials that do not emit harmful gases or particles. However, the installation process may involve adhesives or sealants that could release volatile organic compounds (VOCs) temporarily, which can affect air quality. Proper ventilation during installation and after can mitigate this. Additionally, aluminum sheets can contribute to better air quality by providing a barrier against moisture and mold growth, which can be a concern with other building materials.</p>

- Q: Can 101 aluminum sheets be used in architectural cladding?

- Yes, 101 aluminum sheets can be used in architectural cladding.

- Q: What is the typical tensile strength of aluminum sheets?

- The specific grade or alloy being used can cause variations in the typical tensile strength of aluminum sheets. Typically, the tensile strength of aluminum sheets falls between 20,000 and 50,000 pounds per square inch (psi). It is worth mentioning that this is a wide range and the exact tensile strength can be affected by factors such as the sheet's thickness, the manufacturing process, and any additional treatments or coatings applied to the aluminum. Hence, it is advisable to refer to the manufacturer's or supplier's specifications for accurate information regarding the tensile strength of a particular aluminum sheet.

- Q: What are the standard thicknesses for aluminum sheets utilized in construction?

- <p>Yes, there are standards for the thickness of aluminum sheets used in construction. These standards vary by country and application. In the United States, the Aluminum Association sets standards, such as AA 3003-H14, which is commonly used in construction for thicknesses ranging from 0.020 to 0.250 inches. In Europe, EN 485-2 covers the specifications for aluminum sheet thicknesses. Thicknesses can range from 0.4mm to 6.0mm, depending on the specific requirements of the construction project. It's important to consult the relevant standards for the region and application to ensure compliance and proper material selection.</p>

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Indeed, it is possible to bend or form aluminum sheets without causing cracks or breaks; however, this outcome is contingent upon the thickness of the sheet as well as the bending or forming technique employed. Aluminum, being an exceptionally pliable material, can be easily manipulated into various shapes without fracturing. Nevertheless, if the sheet is excessively thin or if the bending or forming procedure lacks carefulness and precision, there is a possibility of cracks or breaks occurring. To mitigate this risk, it is imperative to utilize appropriate tools and methods, such as a bending brake or a rolling machine, and to ensure that the sheet is not subjected to excessive force or stress during the process. Furthermore, annealing the aluminum sheet prior to bending or forming can enhance its flexibility and diminish the likelihood of cracking. Ultimately, with the correct approach and necessary precautions, it is feasible to successfully bend or form aluminum sheets without encountering cracks or breaks.

- Q: Can aluminum sheet be used for chemical processing?

- Yes, aluminum sheet can be used for chemical processing. Aluminum has excellent corrosion resistance and is often used in chemical processing industries for various applications such as storage tanks, reaction vessels, and heat exchangers.

- Q: Can aluminum sheets be embossed?

- Yes, aluminum sheets can be embossed.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

Send your message to us

Aluminum Oxide Sanding Sheets for Aluminum Alloy Sheet 5083 Shipbuilding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords