Self-adhesive SBS/APP Modified Bitumen Waterproof Membrane With High Quality

- Loading Port:

- Shanghai

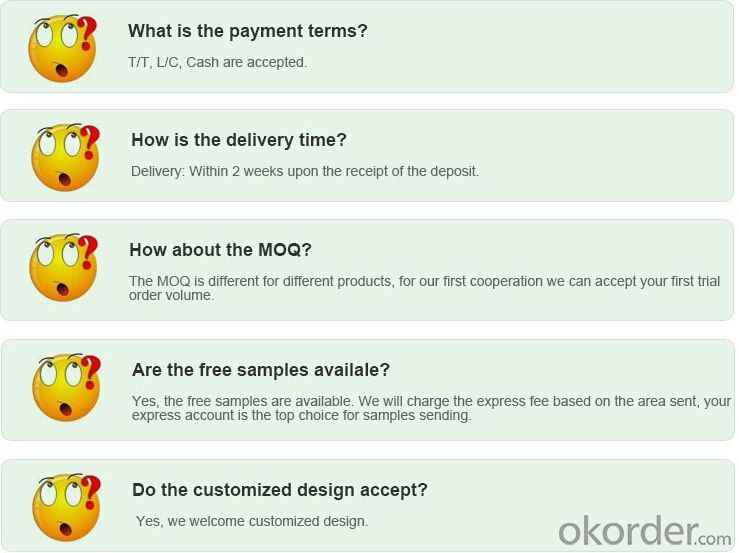

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

Breathable high strength waterproof sheet is specially designed for roof which uses concrete as the basic structure. Compared with other bitumen roofing waterproofs, it has permeability and helps concrete base structure cure, permits humidity out, at the same time waterproof capability is as before.

It is simple to install breathable high strength waterproof sheet, butyl glue ensures reliable paving effect, and it doesn’t require any special techniques from construction personnel, one roll is light enough for one worker to handle. It can be paved on rough concrete surface directly without any adhesive agent or base coating; it can also simplify roofing structure without leveling layer.

Characteristic

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable scope:

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application

The needle-punched polyester is widely used as the carrier for waterproofing membrane production. The membrane made withneedle-punched polyester matis widely used for: Construction waterproofing; Moisture-proof in roof engineering, underground engineering, indoor ground, etc;Corrosion resistance for water pool or building bases.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

product show

\

FAQ

- Q: Are waterproofing membranes resistant to algae growth?

- Yes, waterproofing membranes are generally resistant to algae growth. Waterproofing membranes are designed to be highly durable and resistant to various environmental factors, including the growth of algae. They are typically made of materials such as PVC, TPO, or EPDM that are inherently resistant to algae and other microbial growth. Additionally, waterproofing membranes are often treated with anti-algae and anti-fungal agents during their manufacturing process to further enhance their resistance to algae growth. However, it is important to note that while waterproofing membranes are resistant to algae growth, they may still require regular cleaning and maintenance to ensure their long-term performance and prevent any potential build-up of dirt or debris that could potentially provide a favorable environment for algae to grow.

- Q: Can waterproofing membranes be used in cold climates?

- Yes, waterproofing membranes can be used in cold climates. They are designed to withstand extreme temperatures, including freezing conditions, and provide effective protection against water penetration.

- Q: Can a waterproofing membrane be used for a podium deck?

- Indeed, a podium deck can utilize a waterproofing membrane. A podium deck refers to an elevated platform or structure commonly found in commercial buildings or multi-story residential complexes. Given its raised position, a podium deck is exposed to various weather elements, including rain and moisture. Consequently, it becomes imperative to implement a dependable waterproofing system to shield the underlying structure from water-related harm. A waterproofing membrane emerges as a popular option for podium decks due to its ability to serve as an effective barrier against water infiltration. Generally, this membrane is applied beneath the deck's surface, acting as a protective layer that thwarts water from permeating the underlying structure. Its design prioritizes durability, flexibility, and resistance to weathering, guaranteeing long-term protection for the deck. Additionally, a waterproofing membrane can yield supplementary advantages for a podium deck. It can function as a vapor barrier, preventing the accumulation of moisture within the structure, which could lead to mold growth and material deterioration. Moreover, certain waterproofing membranes offer heightened UV resistance, contributing to the deck's longevity and aesthetic appeal preservation. When selecting a waterproofing membrane for a podium deck, it is crucial to consider factors such as the deck's design, projected foot traffic levels, and local climate conditions. Different membrane types, including sheet membranes, liquid membranes, or spray-applied membranes, may be suitable depending on the specific project requirements. In conclusion, employing a waterproofing membrane indeed proves suitable for a podium deck. It furnishes a reliable and effective solution for safeguarding the deck and underlying structure from water damage, thereby ensuring the durability and functionality of the podium deck.

- Q: Can a waterproofing membrane be used on tunnels with fire protection systems?

- Tunnels equipped with fire protection systems can indeed make use of a waterproofing membrane. It is actually quite common to recommend the use of a waterproofing membrane alongside fire protection systems in tunnels, as it adds an extra layer of safeguarding. The purpose of this membrane is to prevent any water from infiltrating the tunnel, as this could potentially harm the fire protection systems and undermine their effectiveness. By ensuring the tunnel remains watertight, the waterproofing membrane preserves the integrity and functionality of the fire protection systems, enabling them to fulfill their intended purpose in the event of a fire. Moreover, the waterproofing membrane can also serve as a barrier, impeding the spread of fire by blocking the passage of flames and smoke. Nonetheless, it is crucial to ensure that the chosen waterproofing membrane is compatible with the specific fire protection systems employed in the tunnel in order to ensure optimum performance and safety.

- Q: Can a waterproofing membrane be used in bathrooms or showers?

- Certainly, bathrooms or showers can benefit from the use of a waterproofing membrane. In fact, it is strongly advised to incorporate a waterproofing membrane in these spaces to avert water damage and leakage. By serving as a barrier, the waterproofing membrane obstructs water from infiltrating through the walls, floors, and other surfaces in the bathroom or shower. Normally, it is applied prior to tiling or finishing the surfaces, offering an additional shield against moisture and guaranteeing that the underlying structure remains free from dampness. This not only aids in preventing the growth of mold and mildew but also extends the lifespan of the bathroom or shower.

- Q: Can a waterproofing membrane be used for a plaza deck waterproofing?

- Yes, a waterproofing membrane can be used for plaza deck waterproofing. Plaza decks are typically exposed to the elements, including rain and snow, and require a waterproofing system to prevent water infiltration and potential damage to the structure below. Waterproofing membranes are designed specifically for this purpose, offering a barrier against water and protecting the deck from moisture-related issues such as leaks, deterioration, and mold growth. These membranes are typically made from materials such as bitumen, PVC, or EPDM, and are applied in multiple layers to ensure a durable and watertight seal. By using a waterproofing membrane, plaza decks can effectively maintain their structural integrity and longevity.

- Q: Can a waterproofing membrane be used on asphalt surfaces?

- Indeed, asphalt surfaces can benefit from the application of a waterproofing membrane. These membranes, widely employed in construction, are specifically engineered to safeguard against water infiltration. Their versatility allows for application on diverse surfaces, asphalt included. By applying a waterproofing membrane on an asphalt surface, one can effectively thwart water damage, prolong the surface's lifespan, and safeguard the underlying structures. It is crucial to guarantee the compatibility of the chosen waterproofing membrane with asphalt and to adhere to proper installation techniques in order to achieve the best possible outcome.

- Q: Can a waterproofing membrane be used for residential swimming pools?

- Yes, a waterproofing membrane can be used for residential swimming pools. Waterproofing membranes are commonly used in construction to prevent water penetration and can be applied to various surfaces such as concrete, tile, and metal. They create a barrier that prevents water from seeping into the pool structure, which helps to maintain the integrity of the pool and prevent leaks. Additionally, waterproofing membranes can also protect against other forms of damage such as corrosion and deterioration caused by chemicals or harsh weather conditions. It is important to select a high-quality waterproofing membrane that is specifically designed for swimming pool applications to ensure long-lasting protection and durability.

- Q: Can a waterproofing membrane be used in conjunction with other waterproofing products?

- Yes, a waterproofing membrane can be used in conjunction with other waterproofing products. In fact, it is common practice to use multiple waterproofing methods together to provide enhanced protection against water damage. For example, a waterproofing membrane can be used as a primary waterproofing layer, and then complemented with other products such as sealants, coatings, or drainage systems for added durability and performance. The combination of these products can help create a more robust and comprehensive waterproofing system, ensuring maximum protection against water intrusion and preventing potential leaks or moisture-related issues.

- Q: Can a waterproofing membrane be used for water treatment plants?

- Yes, a waterproofing membrane can be used for water treatment plants. Waterproofing membranes are designed to prevent the passage of water and can be used to provide a barrier against water leakage in various structures, including water treatment plants. These membranes can be applied to different areas of the plant, such as tanks, reservoirs, pipes, and basements, to prevent water infiltration and protect the infrastructure from potential damage. Additionally, waterproofing membranes can help maintain the integrity of the water treatment process by ensuring that water remains contained within designated areas and does not seep into surrounding soil or structures.

Send your message to us

Self-adhesive SBS/APP Modified Bitumen Waterproof Membrane With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords