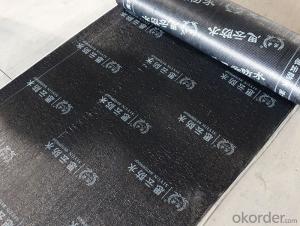

Beijing Good Quality SBS APP Modified Bitumen Waterproof Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

SBS Waterproof Material Self Adhesive Aluminium Membrane is produced with SBS elastomer and bitumen as raw materials, using polyethylene film.

Aluminium foil coated on the upward or no file(both side self-adhesive) while self-adhesive protection layer on the downward

surface.It has a widely prospect new contruction waterproof materials. Good self-adhesion, no leaking,cold flexibility,especially

in self-adhesion. That is unque product in waterproof and application.

Packaging & Shipping

Package and transportation-- SBS waterproof membrane / APP waterproof membrane / Asphalt waterproof membrane for building waterproofing construction :

1. Torch on bitumen membrane sheets 4mm should be stored under dry and ventilated conditions.

2. Different types of membranes must be piled separately.

3. Under usual condition, storage period is one year since production date.

4. Membrane roll should be put vertically during transportation. It should be kept away from sunshine and rainwater.

.

Advantagee

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Application method

1.Make sure the roof deck smooth ,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2.There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3.After application ,a full serious inspection is required to make sure no air bubble ,no fold,no falling away etc to guarantee the waterproof life.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Payment and Delivery:

1. Payment: 50% Deposit by T/T, 50% balance charge by T/T before shipping.

2. Delivery: 3 Working days after received the payment.

Technical Parameters

Item | Index | ||||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

product show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used for a planter box?

- Indeed, a planter box can benefit from the use of a waterproofing membrane. The primary function of a waterproofing membrane is to impede the intrusion of water into the surface it is applied to. Consequently, it is a suitable choice for safeguarding the planter box against moisture-induced harm. By employing a waterproofing membrane on the interior of the planter box, a barrier is established that thwarts the infiltration of water and the potential harm it may inflict upon the wood or material of the planter box. This can prove particularly advantageous when the planter box is persistently exposed to water, such as in outdoor settings or for hydroponic gardening endeavors. In essence, the utilization of a waterproofing membrane for a planter box can contribute to its longevity and ensure its sustained good condition.

- Q: Can a waterproofing membrane be used for bridges or viaducts?

- Yes, a waterproofing membrane can be used for bridges or viaducts. These structures are subjected to various weather conditions, including rain, snow, and humidity, which can cause damage over time if not adequately protected. A waterproofing membrane is designed to create a barrier against water infiltration, preventing moisture from seeping into the bridge or viaduct structure. It helps to preserve the integrity of the concrete or steel components, reducing the risk of corrosion and other forms of deterioration. Additionally, the use of a waterproofing membrane can extend the lifespan of the bridge or viaduct, reducing maintenance and repair costs in the long run.

- Q: Can a waterproofing membrane be used on roofs with slope?

- Yes, a waterproofing membrane can be used on roofs with slope. In fact, it is often recommended to use a waterproofing membrane on sloped roofs to prevent water infiltration and to ensure proper drainage. The membrane is installed beneath the roofing material and acts as a barrier against moisture, helping to protect the roof and the underlying structure from water damage.

- Q: Are waterproofing membranes suitable for wastewater treatment plants?

- Yes, waterproofing membranes are suitable for wastewater treatment plants. Wastewater treatment plants deal with the treatment and processing of wastewater, which contains a variety of chemicals, contaminants, and bacteria. These substances can be highly corrosive and can cause damage to the infrastructure of the plant if not properly protected. Waterproofing membranes provide an effective barrier against water and chemical penetration, preventing leaks, seepage, and corrosion. They can be applied to various areas of the plant, including tanks, basins, pipelines, and concrete structures. Additionally, waterproofing membranes are durable, long-lasting, and can withstand the harsh conditions and chemicals present in wastewater treatment plants. Therefore, using waterproofing membranes in wastewater treatment plants is a recommended practice to ensure the integrity, longevity, and efficiency of the infrastructure.

- Q: Can waterproofing membranes be used for planter boxes?

- Yes, waterproofing membranes can be used for planter boxes. Waterproofing membranes provide a protective barrier against moisture, preventing any water leakage that could damage the planter box or surrounding areas. This helps to preserve the longevity and integrity of the planter box, making it suitable for long-term use in outdoor environments.

- Q: Can a waterproofing membrane be used for a parking garage deck?

- Yes, a waterproofing membrane can be used for a parking garage deck. Waterproofing membranes are commonly used in parking garages to protect the concrete structure from water damage caused by rain, snow, and other environmental factors. These membranes create a barrier that prevents water from penetrating the deck, helping to extend its lifespan and reduce maintenance costs.

- Q: Can a waterproofing membrane be used in areas with heavy foot traffic or vehicle loadings?

- Yes, a waterproofing membrane can be used in areas with heavy foot traffic or vehicle loadings. However, it is important to ensure that the membrane selected is designed specifically for such conditions and is capable of withstanding the expected loads and pressures. Additionally, regular maintenance and inspections are necessary to ensure the membrane remains intact and functional in high-traffic areas.

- Q: How does a waterproofing membrane handle freeze-thaw cycles?

- The ability to endure freeze-thaw cycles is a crucial characteristic of a waterproofing membrane. It must possess specific properties that allow it to expand and contract without compromising its integrity. Freeze-thaw cycles occur when water enters the membrane and freezes during colder temperatures, causing it to expand. When the ice melts during warmer temperatures, the membrane should be able to contract back to its original state. In order to handle freeze-thaw cycles, a waterproofing membrane typically possesses elasticity and flexibility. This enables it to adjust to the expansion and contraction without cracking or breaking. It may also have a low water absorption rate to prevent water from seeping into the membrane. Moreover, the membrane should exhibit excellent adhesion to the substrate to ensure it remains in place during temperature fluctuations. Certain waterproofing membranes incorporate special additives or technology to enhance their freeze-thaw resistance. These additives may consist of polymers or elastomers that enhance the membrane's ability to withstand extreme temperature changes. Furthermore, some membranes have reinforced layers or fabric inserts that provide additional strength and durability, making them better equipped to handle freeze-thaw cycles. All in all, a well-designed waterproofing membrane should effectively endure freeze-thaw cycles by possessing elasticity, flexibility, resistance to water absorption, and strong adhesion to the substrate. This guarantees the longevity of the membrane and prevents water infiltration, ultimately protecting structures from potential damage caused by freeze-thaw cycles.

- Q: Can a waterproofing membrane be used on precast insulation surfaces?

- Yes, a waterproofing membrane can be used on precast insulation surfaces. A waterproofing membrane is designed to provide a protective barrier against water infiltration, and it can be applied to a variety of surfaces, including precast insulation. The membrane helps to prevent water from seeping into the insulation, which can cause damage and reduce its effectiveness. By applying a waterproofing membrane to precast insulation surfaces, you can ensure that the insulation remains dry and maintains its thermal properties over time.

- Q: Can a waterproofing membrane be used on copper surfaces?

- Yes, a waterproofing membrane can be used on copper surfaces. Copper surfaces can be susceptible to corrosion and damage from moisture, so applying a waterproofing membrane can provide an added layer of protection. The membrane will create a barrier that prevents water and moisture from penetrating the copper surface, helping to prevent corrosion and prolong the lifespan of the copper material. It is important to choose a waterproofing membrane that is compatible with copper to ensure proper adhesion and effectiveness. Additionally, proper surface preparation and application techniques should be followed to ensure a successful waterproofing solution for copper surfaces.

Send your message to us

Beijing Good Quality SBS APP Modified Bitumen Waterproof Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords