SBS APP Modified Bitumen Waterproof Membrane With Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

SBS Waterproof Material Self Adhesive Aluminium Membrane is produced with SBS elastomer and bitumen as raw materials, using polyethylene film.

Aluminium foil coated on the upward or no file(both side self-adhesive) while self-adhesive protection layer on the downward

surface.It has a widely prospect new contruction waterproof materials. Good self-adhesion, no leaking,cold flexibility,especially

in self-adhesion. That is unque product in waterproof and application.

Packaging & Shipping

Package and transportation-- SBS waterproof membrane / APP waterproof membrane / Asphalt waterproof membrane for building waterproofing construction :

1. Torch on bitumen membrane sheets 4mm should be stored under dry and ventilated conditions.

2. Different types of membranes must be piled separately.

3. Under usual condition, storage period is one year since production date.

4. Membrane roll should be put vertically during transportation. It should be kept away from sunshine and rainwater.

.

Advantagee

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable

1) Widely used in the industrial and civil building roofing, underground, pool, tunnel, wooden and metal roofing.

2) Specially applied in the oil depot chemical factory, garment factory, and granary.

3) Especially used in cold places.

4) Tape used for sealing all construction material surfaces.

Storage:

Different types or specifications of products should be separated, not mixed.

Keep it dry and ventilated, protected from the sun or rain.

Storage temperature should never be higher than 45 °C. Pile up the membranes flatwise whose stockpile height never exceeds five layers. One layer is guaranteed if it is placed vertically.

Prevent it from inclination or In the process of transportation, it should be lying in case of inclination or lateral pressure. If necessary, cover it with felt-cloth.

Storage time is at least one year from manufacture date on if the product is under normal operation of storage.

Technical Parameters

Item | Index | ||||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

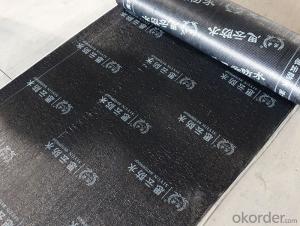

product show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used for a swimming pool deck coating?

- Indeed, a swimming pool deck coating can utilize a waterproofing membrane. Its purpose lies in preventing the infiltration of water and safeguarding the underlying surfaces. When applied with precision, a waterproofing membrane establishes an effective barrier against water and moisture, rendering it an excellent option for a swimming pool deck coating. This solution aids in averting water damage, such as cracking, spalling, or deterioration, while simultaneously providing an anti-slip surface to enhance safety. Moreover, a waterproofing membrane contributes to extending the lifespan of the pool deck by shielding it from water-related complications. In conclusion, opting for a waterproofing membrane as a swimming pool deck coating is a sensible and advantageous decision.

- Q: Are waterproofing membranes resistant to seawater?

- Yes, waterproofing membranes are resistant to seawater. These membranes are designed to provide a barrier against water and are specifically engineered to withstand the harsh conditions of seawater. They are made from materials that are highly resistant to saltwater corrosion and are tested to ensure their effectiveness in preventing water penetration, including the corrosive effects of seawater. This makes waterproofing membranes an ideal choice for applications where seawater exposure is a concern, such as in marine structures, coastal buildings, and swimming pools.

- Q: Does a waterproofing membrane prevent water damage to building materials?

- Yes, a waterproofing membrane is designed to create a barrier that prevents water from seeping into building materials, thus effectively preventing water damage.

- Q: Can a waterproofing membrane be used for above-grade applications?

- Yes, a waterproofing membrane can be used for above-grade applications. Waterproofing membranes are commonly used in construction to prevent water infiltration and damage to structures. While they are often used for below-grade applications such as basements and foundations, waterproofing membranes can also be used above-grade on surfaces such as roofs, decks, and exterior walls. In above-grade applications, waterproofing membranes act as a barrier against moisture, preventing water from seeping into the structure. They are designed to withstand prolonged exposure to the elements, including rain, snow, and UV rays. By effectively sealing the surface, a waterproofing membrane helps to protect the structure from water damage, mold growth, and deterioration. There are different types of waterproofing membranes available for above-grade applications, including liquid-applied membranes, sheet membranes, and self-adhering membranes. These membranes are often made from materials such as modified bitumen, polyurethane, or rubberized asphalt, which provide excellent waterproofing properties. When installing a waterproofing membrane above-grade, proper surface preparation is essential. The surface needs to be clean, dry, and free from any contaminants that could compromise the adhesion of the membrane. Additionally, it is important to follow the manufacturer's instructions and guidelines for application techniques and recommended thickness. In summary, a waterproofing membrane can be used for above-grade applications to effectively protect structures from water infiltration and damage. By choosing the appropriate type of membrane and following proper installation procedures, it is possible to create a durable and reliable waterproofing system for above-grade surfaces.

- Q: Can a waterproofing membrane be used for a foundation wall damp proofing?

- Indeed, foundation wall damp proofing can be achieved by utilizing a waterproofing membrane. The purpose of a waterproofing membrane is to obstruct the flow of water, thus serving as a shield between the foundation wall and the adjacent soil. This protective shield aids in averting moisture seepage into the foundation wall, which can result in dampness and potential water harm. Through the application of a waterproofing membrane onto the foundation wall, an effective damp proofing is achieved, guarding it against water intrusion. Nevertheless, it is crucial to ensure that the installation of the waterproofing membrane is executed accurately, and that all joints and seams are adequately sealed to establish an uninterrupted barrier against water.

- Q: Can a waterproofing membrane be used for elevator pits and machine rooms?

- Yes, a waterproofing membrane can be used for elevator pits and machine rooms. Elevator pits and machine rooms are susceptible to water infiltration due to their location or proximity to underground water sources. This can lead to potential damage to the elevator machinery and electrical systems. To prevent water damage and ensure the longevity of the elevator system, it is crucial to apply a waterproofing membrane to these areas. A waterproofing membrane is a protective layer that is applied to the surface of a structure to prevent water penetration. It acts as a barrier against water and helps to keep the area dry and moisture-free. Waterproofing membranes are typically made of various materials such as bitumen, rubberized asphalt, or liquid-applied coatings. When applied to elevator pits and machine rooms, a waterproofing membrane provides an effective solution to prevent water seepage. It can be installed on the walls, floors, and even the ceiling of these areas to create a watertight seal. The membrane is resistant to water pressure, ensuring that no water enters the elevator pit or machine room. Moreover, waterproofing membranes also protect the elevator machinery and electrical systems from potential damage caused by water exposure. These systems are sensitive to moisture and can malfunction or corrode if exposed to water. By using a waterproofing membrane, the risk of such damage is significantly reduced, leading to improved reliability and longevity of the elevator system. In conclusion, a waterproofing membrane is a suitable solution for elevator pits and machine rooms as it effectively prevents water infiltration, protects the elevator machinery and electrical systems, and ensures the overall functionality and durability of the elevator system.

- Q: How long do waterproofing membranes last?

- The lifespan of waterproofing membranes can vary depending on various factors such as the type of membrane used, the quality of installation, environmental conditions, and maintenance practices. Generally, high-quality waterproofing membranes can last anywhere from 10 to 50 years. For example, bituminous membranes, which are commonly used in roofing applications, typically have a lifespan of around 20 to 30 years. On the other hand, more advanced synthetic membranes like PVC or TPO can last up to 40 years or even longer. However, it's important to note that these estimations are based on ideal conditions and regular maintenance. Factors such as exposure to extreme weather conditions, improper installation, lack of maintenance, or physical damage can significantly reduce the lifespan of the membranes. Therefore, it is crucial to consult with professionals and follow manufacturer's recommendations for maintenance to ensure the longevity of the waterproofing membranes.

- Q: Can a waterproofing membrane be used on masonry surfaces?

- Yes, a waterproofing membrane can be used on masonry surfaces. In fact, applying a waterproofing membrane on masonry surfaces is a common solution to prevent water infiltration and damage. Masonry surfaces such as concrete, brick, or stone are porous and can absorb water, which can lead to structural damage, mold growth, and deterioration over time. A waterproofing membrane acts as a barrier, preventing water from seeping into the masonry and protecting it from moisture-related issues. It is important to choose a waterproofing membrane that is specifically designed for masonry surfaces and follow the manufacturer's instructions for proper application.

- Q: Can a waterproofing membrane be used on precast plaster surfaces?

- Yes, a waterproofing membrane can be used on precast plaster surfaces. Precast plaster surfaces are typically porous and can absorb water, leading to potential water damage and deterioration over time. Applying a waterproofing membrane can help prevent water penetration and protect the surface from moisture-related issues such as mold, mildew, and efflorescence. The waterproofing membrane acts as a barrier, preventing water from seeping into the plaster and causing damage. It is important to ensure that the membrane is compatible with the specific type of plaster and is applied correctly to achieve optimal waterproofing results.

- Q: Can waterproofing membranes be used in wet areas like bathrooms?

- Yes, waterproofing membranes can indeed be used in wet areas like bathrooms. In fact, it is highly recommended to use waterproofing membranes in bathroom areas to prevent water damage and leakage. These membranes are specifically designed to create a barrier against moisture, ensuring that water does not seep through the walls, floors, or other surfaces of the bathroom. By applying a waterproofing membrane, you can effectively protect the underlying structure from water damage, mold growth, and other issues caused by prolonged exposure to moisture. This is especially important in wet areas like bathrooms where water is constantly present. Waterproofing membranes are available in various forms such as sheet membranes, liquid membranes, and even pre-formed shower trays. They can be applied to walls, floors, shower enclosures, and other surfaces to create a watertight seal. It is crucial to properly install and maintain the waterproofing membrane as per manufacturer guidelines to ensure its effectiveness and longevity. Therefore, if you are considering renovating or building a bathroom, using waterproofing membranes is highly recommended to ensure a durable and moisture-resistant space.

Send your message to us

SBS APP Modified Bitumen Waterproof Membrane With Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords