Self Adhesive Bitumen Waterproof Membrane for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

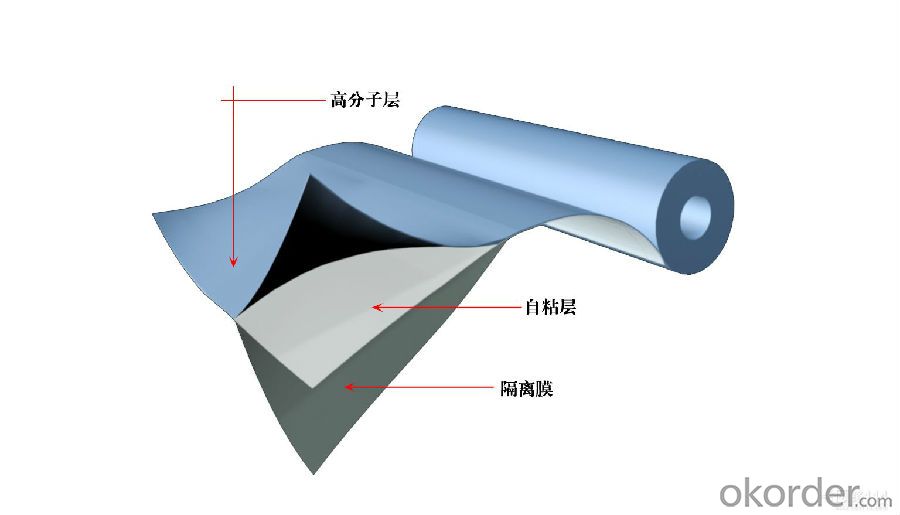

Self adhesive waterproofing material ismade by saturating the base in bitumen, or thermoplastic elastomer (such as styrene butadiene), reinforced with polyester or fiberglass, finishing the upward face with fine sands, mineral slates (or grains) or polythene membrane etc. It has the outstanding performance such as: convenient to apply, no environmental pollution etc. This product is consisting of two kinds: without reinforcement and polyester reinforcement.

Specification

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Advantages

1) Cold-applied construction with no open flame and self-adhesion without bonding agent make it safe, low- carbon, environmental, and economical.

2) Excellent adhesive performance guarantees the integrity of waterproof layer.

3) Good rubber elasticity, elongation and shear stress.

4) Good low-temperature property.

FAQ

1. Is sample available before place orders?

A: Yes, sample is ok.

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Are waterproofing membranes resistant to high-pressure water jets?

- Waterproofing membranes are known for their ability to resist high-pressure water jets. They are specifically designed to create a barrier against water penetration and undergo testing to ensure their durability against different water pressures. The level of resistance may differ depending on the type and quality of the membrane. Nonetheless, waterproofing membranes are engineered to withstand high-pressure water jets, effectively safeguarding against water infiltration and potential harm to the underlying structure.

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Yes, a waterproofing membrane does require special considerations for installation in seismic zones. Seismic zones are prone to earthquakes and ground movements, which can cause significant stress and strain on the building structure. When installing a waterproofing membrane in such areas, it is crucial to ensure that it can withstand the potential movements and vibrations caused by seismic activities. Some of the special considerations for installing a waterproofing membrane in seismic zones include: 1. Flexibility: The membrane should have sufficient flexibility to accommodate the movement of the building structure during an earthquake. It should be able to stretch, contract, and withstand dynamic forces without tearing or losing its waterproofing properties. 2. Compatibility: The waterproofing membrane should be compatible with the building materials and systems used in seismic zones. It is important to select a membrane that can bond well with the substrate and other construction components to create a seamless and robust waterproofing system. 3. Reinforcement: In high seismic areas, it is recommended to reinforce the waterproofing membrane with additional layers or reinforcements. This can be done by adding a fabric or mesh layer to enhance the membrane's tensile strength and resistance to tearing caused by seismic movements. 4. Proper installation techniques: The installation of the waterproofing membrane in seismic zones should follow specific guidelines and techniques to ensure its effectiveness. It may involve using specific adhesives, primers, or mechanical fastening systems to secure the membrane properly. 5. Quality control: Regular inspections and quality control measures should be implemented during and after the installation process. This helps to identify any potential issues or deficiencies in the waterproofing system, allowing for prompt repairs or adjustments to be made. By addressing these special considerations, the installation of a waterproofing membrane in seismic zones can help protect the building structure from water intrusion and potential damage caused by earthquakes. Consulting with experienced professionals and following industry standards and guidelines is crucial to ensure a successful installation in these challenging environments.

- Q: Can a waterproofing membrane be used for hospitals or healthcare facilities?

- Hospitals and healthcare facilities can utilize a waterproofing membrane. These membranes are commonly employed in different construction contexts, including hospitals and healthcare facilities, to safeguard against water infiltration and moisture harm. The purpose of these membranes is to establish a barrier that prevents water and moisture from permeating the building envelope, thus ensuring a dry and secure environment. Waterproofing membranes offer several advantages in hospitals and healthcare facilities, where hygiene and cleanliness are paramount. Firstly, they aid in the prevention of mold, mildew, and bacteria growth, which can thrive in damp areas. This is crucial in healthcare settings where patient health and safety are of utmost importance. Moreover, the use of waterproofing membranes safeguards the structural integrity of the building by preventing water damage, such as leaks, that can compromise the stability of the structure. They also contribute to the longevity of the building by preventing damage to walls, floors, and other surfaces caused by water infiltration. Additionally, waterproofing membranes can be tailored to meet the specific needs of hospitals or healthcare facilities. They can be applied to various areas, including basements, foundations, roofs, and bathrooms, to ensure comprehensive water protection throughout the facility. Furthermore, these membranes can be integrated with other waterproofing systems, such as drainage systems, to enhance their effectiveness. In conclusion, waterproofing membranes are a valuable solution for hospitals and healthcare facilities as they provide vital protection against water intrusion, moisture damage, and mold growth. By implementing these membranes, healthcare facilities can maintain a safe, clean, and durable environment for patients, staff, and visitors.

- Q: Can a waterproofing membrane be used in cold climates?

- Indeed, a waterproofing membrane is suitable for use in cold climates. It is highly advisable to utilize a waterproofing membrane in cold climates to safeguard structures from moisture damage caused by snow, ice, and freezing temperatures. These membranes are engineered to possess flexibility and durability, enabling them to endure extreme temperature fluctuations without experiencing cracks or deterioration. They establish a barrier that thwarts water from permeating the structure, a critical factor in cold climates where water can freeze and expand, resulting in substantial harm to buildings and infrastructure. Additionally, certain waterproofing membranes are specifically formulated to excel in cold weather conditions, offering heightened resistance to freeze-thaw cycles and ensuring long-term protection against water infiltration. Therefore, it is imperative to employ a high-quality waterproofing membrane in cold climates to uphold the integrity and longevity of structures.

- Q: Can a waterproofing membrane be covered or concealed by other finishes or materials?

- Yes, a waterproofing membrane can be covered or concealed by other finishes or materials. In fact, it is common practice to do so in construction projects. The purpose of a waterproofing membrane is to provide a barrier against water infiltration and protect the underlying structure. It is typically installed on surfaces such as roofs, foundations, or walls before other finishes or materials are applied. Covering the waterproofing membrane with other finishes or materials serves two main purposes. Firstly, it helps to enhance the aesthetics of the structure. Whether it is a roof, a bathroom, or a basement, concealing the waterproofing membrane allows for the installation of more visually appealing finishes like tiles, paints, or decorative elements. Secondly, covering the waterproofing membrane also provides an additional layer of protection. While the membrane itself is designed to be resistant to water, it can still be susceptible to damage from UV rays, foot traffic, or general wear and tear. By adding other finishes or materials on top, such as protective coatings, tiles, or concrete, the waterproofing membrane is shielded from potential damage, prolonging its lifespan and effectiveness. However, it is important to note that proper installation and compatibility between the waterproofing membrane and the covering materials are crucial. The covering materials should not compromise the integrity of the membrane or create any points of weakness. Additionally, any penetrations or joints in the covering materials must be meticulously sealed to maintain the waterproofing system's effectiveness. Therefore, while a waterproofing membrane can be covered or concealed by other finishes or materials, it is essential to follow manufacturer guidelines and consult with professionals to ensure that the overall waterproofing system remains intact and performs as intended.

- Q: Can a waterproofing membrane be used for a school building foundation?

- Yes, a waterproofing membrane can be used for a school building foundation. Waterproofing membranes are commonly used in construction to prevent water penetration into the foundation, which helps protect the building from potential water damage.

- Q: Can a waterproofing membrane be used for podium decks or plaza areas?

- Podium decks or plaza areas can benefit from the application of a waterproofing membrane. It is highly recommended to utilize this protective layer in order to safeguard the underlying structure from water-related harm. Given their exposure to the elements, podium decks and plaza areas are susceptible to water infiltration. By implementing a waterproofing membrane, water seepage into the lower layers can be effectively prevented, thus ensuring the long-lasting durability and structural integrity of the deck or plaza. Furthermore, this waterproofing membrane is also capable of shielding spaces beneath the deck or plaza, such as basements or parking garages, from potential water damage. Therefore, it is crucial to select a top-notch waterproofing membrane specifically designed for outdoor purposes, and to carefully adhere to the manufacturer's instructions regarding proper installation and maintenance.

- Q: How does a waterproofing membrane handle exposure to chemicals or solvents?

- Protection against water and moisture is the primary purpose of a waterproofing membrane. However, the membrane's ability to resist chemicals or solvents varies based on the type used. Various waterproofing membranes are available on the market, each possessing its own unique properties and capabilities. Certain membranes are specifically designed to withstand exposure to chemicals or solvents. These membranes are typically constructed using materials like PVC, TPO, or CPE. These materials offer exceptional chemical resistance, making them highly effective in environments where contact with chemicals or solvents is anticipated. In contrast, some waterproofing membranes may not possess the same level of resistance to chemicals or solvents. For example, membranes composed of bitumen or asphalt may experience degradation or damage when exposed to certain chemicals or solvents. In such cases, additional protective measures may be necessary, such as applying a chemical-resistant coating or implementing a secondary barrier to prevent direct contact between the membrane and the chemicals or solvents. When selecting a waterproofing membrane, it is crucial to consider the specific requirements of the project and the potential exposure to chemicals or solvents. Seeking guidance from a professional waterproofing contractor or manufacturer can help determine the most suitable membrane for the intended application. Regular inspections, maintenance, and proper cleaning of the membrane are also essential to ensure its longevity and performance when faced with chemicals or solvents.

- Q: Can a waterproofing membrane be used for exterior applications?

- Yes, a waterproofing membrane can be used for exterior applications. Waterproofing membranes are specifically designed to protect surfaces from water infiltration and can be used in various exterior applications, such as roofs, balconies, decks, foundations, and below-grade structures. These membranes are typically made from durable materials that can withstand harsh weather conditions, UV exposure, and temperature fluctuations. They provide a protective barrier against moisture, preventing water damage, leaks, and mold growth. Additionally, waterproofing membranes can be applied to different types of surfaces, including concrete, wood, metal, and even existing roofing systems, making them versatile for exterior applications.

- Q: Can a waterproofing membrane be used in bridge decks or roadways?

- Yes, a waterproofing membrane can be used in bridge decks or roadways to enhance durability, prevent water damage, and extend the lifespan of the structure.

Send your message to us

Self Adhesive Bitumen Waterproof Membrane for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords