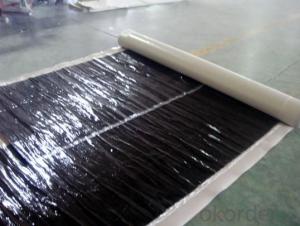

Aluminum Film Self Adhesive Bitumen Waterproof Membrane for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Self adhesive waterproofing material ismade by saturating the base in bitumen, or thermoplastic elastomer (such as styrene butadiene), reinforced with polyester or fiberglass, finishing the upward face with fine sands, mineral slates (or grains) or polythene membrane etc. It has the outstanding performance such as: convenient to apply, no environmental pollution etc. This product is consisting of two kinds: without reinforcement and polyester reinforcement.

Specification

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Advantages

Excellent waterproofness;

Unique creep properties and self-healing capability which can recover by itself;

Strong adhesion which can targeted the leakage in localized areas;

Tight joints, good extensibility;

Good stability and corrosion resistance, lasting effect.

Construction Process

Base course treatment Line plotting Pre-applied membrane Scrap cement glue Pave membrane Roll and exhaust Seal the joints Acceptance check

Six Performance Boost

Double deck

Size stability and tear resistance

Flexible texture and root resistance

Anti-ultraviolet for 6 months

High elongation and stretch ability

Great thermo stability

FAQ

1. Is sample available before place orders?

A: Yes, sample is ok.

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Are there any specific considerations for installing a waterproofing membrane on metal surfaces?

- Installing a waterproofing membrane on metal surfaces requires specific considerations. It is crucial to choose a membrane that is compatible with the type of metal being used, as some membranes may not adhere well to certain metals. Proper preparation of the metal surface is also important, which may involve thorough cleaning to remove dirt and contaminants, as well as priming to improve adhesion. Another factor to consider is the expansion and contraction of the metal surface due to temperature changes. This movement can potentially affect the performance of the waterproofing membrane, so it is necessary to select a membrane that can accommodate the metal's movement without compromising its waterproofing capabilities. The type of waterproofing membrane being used is also significant. Liquid-applied membranes, sheet membranes, and peel-and-stick membranes each have their own installation requirements, and it is important to follow the manufacturer's guidelines for proper installation on metal surfaces. Additionally, other factors such as exposure to UV radiation, potential for corrosion, and compatibility with other building materials or systems should be taken into account. Considering these factors will help ensure a successful and long-lasting installation of a waterproofing membrane on metal surfaces.

- Q: Are waterproofing membranes resistant to saltwater?

- Waterproofing membranes, in general, possess resistance to saltwater. Their purpose is to establish a barricade that hinders water infiltration into surfaces such as roofs, walls, or foundations. These membranes are created using materials like rubber, polyethylene, or PVC, which have an inherent ability to withstand the corrosive impact of saltwater. This resistance enables waterproofing membranes to adequately safeguard structures and surfaces against water-induced harm, even in saltwater surroundings. Nonetheless, it is crucial to select a waterproofing membrane specifically tailored for saltwater applications in order to guarantee optimal effectiveness and durability.

- Q: Can a waterproofing membrane be used for a shopping mall?

- Indeed, a waterproofing membrane is suitable for the application in a shopping mall. Due to its multiple levels and extensive surface area, a shopping mall is prone to water infiltration from various sources such as rain, plumbing leaks, and others. By incorporating a waterproofing membrane, one can effectively safeguard the structure and its contents against water damage. Typically, this membrane is installed on the exterior walls, roofs, and foundation of the shopping mall to establish a barrier against moisture penetration. Acting as a protective layer, it effectively prevents water from seeping into the building, thereby minimizing the risk of structural deterioration, mold growth, and related problems. Moreover, a properly installed waterproofing membrane can also augment energy efficiency by reducing heat loss and preventing water-induced deterioration of insulation materials. Thus, employing a waterproofing membrane is a prudent decision to ensure the long-lasting durability and functionality of a shopping mall.

- Q: Can a waterproofing membrane be used on modified bitumen roofs?

- A waterproofing membrane is capable of being utilized on modified bitumen roofs. In fact, it is quite customary to apply a waterproofing membrane on top of modified bitumen roofs in order to provide an extra layer of defense against water infiltration. This is particularly crucial in regions where heavy rainfall occurs or where the roof is frequently exposed to water. The waterproofing membrane serves to seal any potential cracks or openings in the modified bitumen roofing system, thereby preventing water from penetrating and causing damage to the underlying structure. Moreover, the waterproofing membrane can also bolster the overall durability and longevity of the roof by shielding it from the detrimental effects of moisture.

- Q: Can a waterproofing membrane be used for theme parks or amusement centers?

- Yes, a waterproofing membrane can be used for theme parks or amusement centers. These types of facilities often have water features, pools, or water rides that require effective waterproofing to prevent leaks or water damage. Waterproofing membranes provide a reliable and durable solution to keep these areas watertight, ensuring the safety and longevity of the park or center.

- Q: Can a waterproofing membrane be used in balconies or decks?

- Yes, a waterproofing membrane can be used in balconies or decks. Waterproofing membranes are specifically designed to prevent water penetration and protect underlying structures from moisture damage. Balconies and decks are often exposed to the elements, including rain and snow, which can lead to water damage and deterioration. By installing a waterproofing membrane, it creates a barrier that prevents water from seeping into the underlying structure, ensuring its longevity and durability. Additionally, waterproofing membranes can also protect against other forms of water damage, such as mold and mildew growth, which can be detrimental to the integrity of the balcony or deck. Overall, using a waterproofing membrane in balconies or decks is an effective solution to maintain their functionality and extend their lifespan.

- Q: Can a waterproofing membrane be used for storage tanks or containment areas?

- Storage tanks or containment areas can utilize a waterproofing membrane to prevent water or liquid penetration. These membranes serve as a barrier against such infiltrations and are therefore ideal for containment purposes. Rubber, PVC, or bitumen are commonly used materials for these membranes due to their water-resistant properties. They can be applied either internally or externally to storage tanks or containment areas to safeguard against leaks and moisture-related deterioration. Moreover, the use of waterproofing membranes aids in preventing the development of mold or mildew, thereby ensuring a secure and hygienic environment for stored materials or liquids.

- Q: Can a waterproofing membrane be used for loading docks?

- Yes, a waterproofing membrane can be used for loading docks. Waterproofing membranes are commonly used in construction and can provide a protective barrier against water intrusion, which can be beneficial for loading docks that may be exposed to rain, snow, or other forms of moisture. By applying a waterproofing membrane to the surface of the loading dock, it can help prevent water damage, deterioration, and potential safety hazards.

- Q: Can a waterproofing membrane be used on precast galvanized surfaces?

- Yes, a waterproofing membrane can be used on precast galvanized surfaces. The waterproofing membrane is designed to provide a protective barrier against water penetration, and it can be applied to various surfaces including precast galvanized surfaces. The membrane helps to prevent water from seeping into the surface, protecting the underlying structure from moisture damage. However, it is important to ensure that the precast galvanized surface is properly prepared before applying the membrane, as any loose or flaking galvanized coating should be removed to ensure proper adhesion of the membrane. Additionally, it is advisable to consult with the manufacturer or supplier of the waterproofing membrane to ensure that it is compatible with galvanized surfaces and to follow their recommended application guidelines for best results.

- Q: Can a waterproofing membrane be used for planter boxes and green roofs?

- To ensure the longevity and functionality of planter boxes and green roofs, it is highly recommended to use a waterproofing membrane. This membrane acts as a barrier, preventing water from causing damage to the underlying structures. For planter boxes, a waterproofing membrane is crucial in order to prevent water leakage and protect the surrounding structures. Additionally, it aids in retaining moisture within the planter box, ensuring adequate hydration for the plants. Similarly, green roofs require a waterproofing membrane to prevent water from infiltrating the roof structure and causing leaks or structural damage. This membrane acts as a protective layer, facilitating proper drainage and preventing water accumulation on the roof surface. When choosing a waterproofing membrane for planter boxes and green roofs, durability, flexibility, and resistance to root penetration should be taken into consideration. Some membranes are specifically designed for these applications and offer additional features such as root barriers to prevent damage caused by plant roots penetrating the membrane. In conclusion, a waterproofing membrane is an indispensable component for planter boxes and green roofs. It serves to prevent water leakage, retain moisture, and safeguard the underlying structures from potential damage caused by water infiltration.

Send your message to us

Aluminum Film Self Adhesive Bitumen Waterproof Membrane for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords