Seamless Steel Pipe Line Pipe ASTM A106, ASTM A53, China Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Full series of products provides an easier access for one stop purchase

▲ Line pipe

▲ Tubing and casing

▲ L & M & H boiler tube

▲ Gas cylinder tube & pipe

▲ Mechanical & Structural pipe

▲ Ship-building tube & pipe

▲ Automobile tube & pipe

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

1.Seamless pipe professor

2.MTC,ISO,API certificate

3.ASTM,DIN,BS,JIS,GB

4.On time delivery

5.Big store,excellent package

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

● Full series of products provides an easier access for one stop purchase

▲ Electric Resistance Welded (ERW) Steel Pipe

▲ Longitudinal Submerged Arc Welded (LSAW) Steel Pipe

▲ Spiral Submerged Arc Welded (SSAW) Steel Pipe

▲ Hollow Section (Square and Rectangle Pipe)

▲ Hot Dipped Galvanized Steel Pipe

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

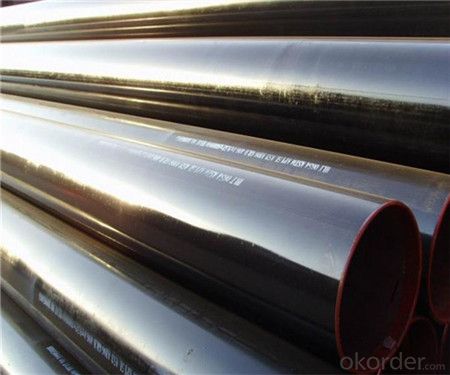

6、Seamless Pipe ASTM A106/53 Images:

- Q: Can stainless steel pipes be used for irrigation systems?

- Indeed, irrigation systems can utilize stainless steel pipes. Stainless steel boasts exceptional corrosion resistance, rendering it a prime selection for water-related purposes. It can endure the demanding conditions inherent in irrigation systems, such as chemical exposure, fertilizers, and fluctuating temperatures. Moreover, stainless steel pipes exhibit durability and possess a lengthy lifespan, guaranteeing the irrigation system's longevity. Furthermore, they deliver superb flow rates and can withstand high-pressure water without experiencing leakage or harm. Consequently, stainless steel pipes represent a dependable and effective choice for irrigation systems.

- Q: How do you prevent freezing in stainless steel pipes?

- To prevent freezing in stainless steel pipes, there are several measures that can be taken: 1. Insulate the pipes: Insulation is one of the most effective ways to prevent freezing. Wrap the stainless steel pipes with insulation sleeves or use foam pipe insulation. This will help to maintain the temperature of the pipes and prevent them from getting too cold. 2. Apply heat tracing: Heat tracing is another effective method to prevent freezing. It involves installing electric heat cables along the length of the pipes. These cables generate heat and keep the pipes warm, preventing freezing. 3. Maintain a constant temperature: Ensure that the area where the stainless steel pipes are located is properly heated. If the pipes are exposed to extreme cold temperatures, it is important to maintain a constant temperature in that area. This can be achieved by using space heaters or by insulating the surrounding walls to retain heat. 4. Keep the water flowing: Moving water is less likely to freeze than stagnant water. If the stainless steel pipes are used to transport water, it is important to keep the water flowing through them, even if it's just a small trickle. This continuous flow will help prevent freezing. 5. Seal any air leaks: Inspect the area around the stainless steel pipes for any air leaks or drafts. Cold air entering the space can cause the pipes to freeze. Seal any gaps or cracks with weatherstripping or caulk to prevent the entry of cold air. 6. Monitor the temperature: Install a thermometer in the area where the stainless steel pipes are located to monitor the temperature. This will help you identify any potential freezing risks and take necessary precautions in advance. By implementing these preventive measures, you can effectively protect your stainless steel pipes from freezing and avoid potential damage.

- Q: What is the difference between seamless and precision stainless steel pipes?

- Seamless and precision stainless steel pipes vary in how they are made and their performance characteristics. Seamless stainless steel pipes are created through extrusion or piercing, where a solid cylindrical billet is heated and a piercing rod forms a hollow tube. This process ensures a smooth and even surface without any seams or welds. The absence of seams eliminates the risk of leakage or weak points, making seamless pipes highly reliable and suitable for a range of uses. On the other hand, precision stainless steel pipes are manufactured through cold-drawn or cold-rolled methods. This involves further processing a seamless pipe to achieve precise dimensions, tolerances, and surface finishes. The precision process enhances the mechanical properties of the pipe, such as strength, hardness, and durability. Precision pipes are commonly used in industries that require tight tolerances and superior surface quality, like automotive, aerospace, and medical applications. In terms of performance, seamless stainless steel pipes offer excellent corrosion and high temperature resistance, as well as good mechanical properties. They are often used in industries such as oil and gas, chemical processing, and power generation, where reliability and strength are vital. Precision stainless steel pipes, on the other hand, are known for their dimensional accuracy, smooth surface finishes, and superior mechanical properties. They are commonly used in precision engineering, instrumentation, and high-performance applications. In summary, the main difference between seamless and precision stainless steel pipes lies in their manufacturing process and intended applications. Seamless pipes are produced without any seams, providing excellent reliability. Precision pipes undergo further processing to achieve precise dimensions and superior surface quality for specific industries and applications.

- Q: Are stainless steel pipes suitable for liquid storage tanks?

- Yes, stainless steel pipes are suitable for liquid storage tanks. Stainless steel has excellent corrosion resistance properties, making it ideal for storing various liquids, including water, chemicals, and food products. The material is highly resistant to rust, oxidation, and staining, ensuring that the stored liquids remain uncontaminated. Stainless steel pipes also have high strength and durability, allowing them to withstand the pressure and weight of the stored liquids. Additionally, stainless steel is easy to clean and maintain, making it a reliable choice for liquid storage applications.

- Q: What's the easiest way to distinguish between stainless steel 202 and 304?

- Not bad money to use 304 of the durability, a few years later, if the price increases, maybe scrap can sell back the cost of moneyIdentification: the only way for you is to go to Taobao to buy potions and estimate where your hardware parts might be soldOther methods are not good, the naked eye can not tell, we are not able to distinguish between the industry are relying on syrup202 can also be used but a guarantee and profiteers will give you for 201 anyway you do not201 did not rust for 2-3 years

- Q: How can the inner walls of stainless steel tubes be polished?

- Electropolishing is thrown to the workpiece as anode, insoluble metal poles at the same time as the cathode, immersed into electrolytic cell, with the direct current produced anodic dissolution selectively, so as to achieve the surface brightness increasing effect. Specific can be used to search "what is electrolytic polishing" can understand!

- Q: Can stainless steel pipes be insulated?

- Yes, stainless steel pipes can be insulated. Insulation can be added to stainless steel pipes to prevent heat loss, condensation, and to enhance energy efficiency in various applications such as industrial processes, HVAC systems, and plumbing.

- Q: What are the common joining methods for stainless steel pipes?

- The common joining methods for stainless steel pipes include welding, threaded connections, and flanged connections.

- Q: Are stainless steel pipes suitable for abrasive media?

- Yes, stainless steel pipes are suitable for abrasive media. Stainless steel is known for its high resistance to corrosion and wear, making it an excellent choice for handling abrasive materials. Its durability and strength ensure that it can withstand the erosive properties of abrasive media, making stainless steel pipes a reliable option for such applications.

- Q: Can stainless steel pipes be used in chemical processing plants?

- Yes, stainless steel pipes can be used in chemical processing plants. Stainless steel is highly resistant to corrosion, making it suitable for handling various chemicals and corrosive substances commonly found in such plants. Additionally, stainless steel pipes offer high strength, durability, and versatility, making them a preferred choice for conveying fluids and gases in chemical processing industries.

Send your message to us

Seamless Steel Pipe Line Pipe ASTM A106, ASTM A53, China Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords