Seamless Steel Pipe ASTM A106/A53/API5L Gr.B Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B description:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell.

As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable.

Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Features :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Specification:

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | He Bei, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery of CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 30-45days after received 30%TT |

FAQ of Seamless Pipe ASTM A106/53:

①Quality

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②Price

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

Why us?

▲ CNBM is a state owned enterprise, which background ensures it of funds support and preferential policies

provide by ministry of commerce.

▲ CNBM enjoys a sound reputation both at home and aboard. The company stands a first-rate credit status

and has gained the access to preferential loans through a lot of international banking organizations.

▲ The company is renowned of it manufacturing capabilities and overall sourcing abilities. It has a long

track proven record of strategic cooperation with leading players in steel industry.

▲ Brand name “CMAX” commit to the best quality products and high cost effectiveness which ensures your

company a booming development & success.

Professional teams ensure a high efficiency of your purchase

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

Looking forward to doing the corporation with you

Any question, kindly feel free to contact us !

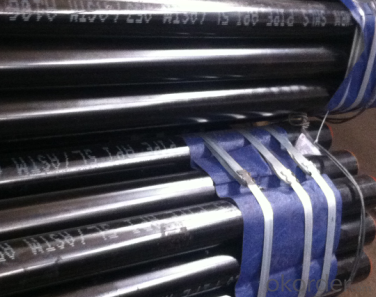

CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Images:

- Q: What is the average cost of steel pipes?

- The average cost of steel pipes can vary significantly depending on factors such as size, grade, and quantity needed. Therefore, it is difficult to provide a specific average cost without more information.

- Q: What is the tensile strength of steel pipes?

- The grade and type of steel used can cause variation in the tensile strength of steel pipes. However, steel pipes generally possess a high tensile strength. Carbon steel pipes typically have a tensile strength range from 370 to 700 MPa, while alloy steel pipes can have a tensile strength range from 770 to 1200 MPa. These impressive tensile strengths enable steel pipes to withstand substantial pressure and stress, making them suitable for diverse applications in industries like construction, oil and gas, and automotive. It is important to recognize that factors like the manufacturing process, heat treatment, and the presence of defects or imperfections can also impact the tensile strength of steel pipes. Hence, it is recommended to consult the manufacturer's specifications or industry standards to determine the precise tensile strength of a specific steel pipe.

- Q: Can steel pipes be used for wastewater treatment systems?

- Yes, steel pipes can be used for wastewater treatment systems. Steel pipes are commonly used in wastewater treatment systems due to their durability, corrosion resistance, and ability to withstand high pressures and temperatures. Additionally, steel pipes can be easily welded and have a long lifespan, making them a suitable choice for transporting and distributing wastewater within treatment facilities.

- Q: What are the different methods of welding steel pipes?

- There are several different methods of welding steel pipes, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW). Each method has its own advantages and is used depending on factors such as the thickness of the pipes, the type of steel being welded, and the desired outcome.

- Q: What are the different grades of steel used for manufacturing pipes?

- The different grades of steel commonly used for manufacturing pipes include carbon steel, alloy steel, and stainless steel.

- Q: How are steel pipes insulated against heat loss?

- Steel pipes are commonly insulated against heat loss by applying a layer of thermal insulation material around the pipes. This insulation material can be in the form of foam, mineral wool, or fiberglass. The insulation is typically wrapped tightly around the pipes and secured with adhesive or tape to ensure proper coverage. This insulation layer helps to reduce heat transfer through the pipe walls, thereby minimizing heat loss. Additionally, the insulation may be covered with a protective jacket or coating to provide further protection against external elements.

- Q: What kinds of steel pipe are divided into?

- According to the weld shape can be divided into longitudinal welded pipe and spiral welded pipeStraight welded pipe: the production process is simple, high production efficiency, low cost, rapid developmentSpiral welded pipe: strength ratio of longitudinal welded pipe is high, with a narrow billet production of large diameter pipe, also can use the blank production of the width of the same diameter of different pipe. But with the same length of straight pipe, weld length of 30~100%, and the production rate is low. Therefore, the smaller diameter pipe most used straight large diameter pipe welding, mostly using spiral welding.Dividedagain general welded pipe, galvanized pipe, blowing pipe, wire tube, pipe metric, roller tube, deep well pump, tube for automobile, transformer tube, welding, welding of thin-walled tube shaped tube and spiral welded pipe.General general pipe: pipe used for conveying the low-pressure fluid. Q195A, Q215A and Q235A made of steel. Also can be used for easy welding of mild steel. The other pipe to conduct water pressure, bending and flattening test, have certain requirements on the surface quality, usually the delivery length is 4-10m, often requires a fixed length (or size) of delivery. The specifications of welded pipe with nominal diameter (mm or inches) nominal diameter and different pipe wall thickness, according to the provisions of general steel and thicker steel two, steel pipe end is divided according to form of threaded and non threaded two.

- Q: Galvanized steel pipe in addition to good rust resistance, what are the advantages?

- It has the characteristics of corrosion resistance and wear resistance, so it can be used longer;

- Q: How are steel pipes protected against rust and corrosion?

- Steel pipes are protected against rust and corrosion through various methods such as applying protective coatings, galvanizing, and utilizing corrosion-resistant alloys.

- Q: What is the difference between steel pipes and concrete-lined pipes?

- Steel pipes are made entirely of steel and are known for their strength and durability. They are commonly used in various applications, including transporting liquids and gases, as well as structural support. On the other hand, concrete-lined pipes are made of steel with a layer of concrete applied to the inner surface. This concrete lining provides additional protection against corrosion and abrasion, making them suitable for transporting corrosive materials or in aggressive environments. The concrete lining also helps in reducing friction within the pipe, resulting in improved flow efficiency.

Send your message to us

Seamless Steel Pipe ASTM A106/A53/API5L Gr.B Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords