SS 201 Stainless Steel Pipe Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

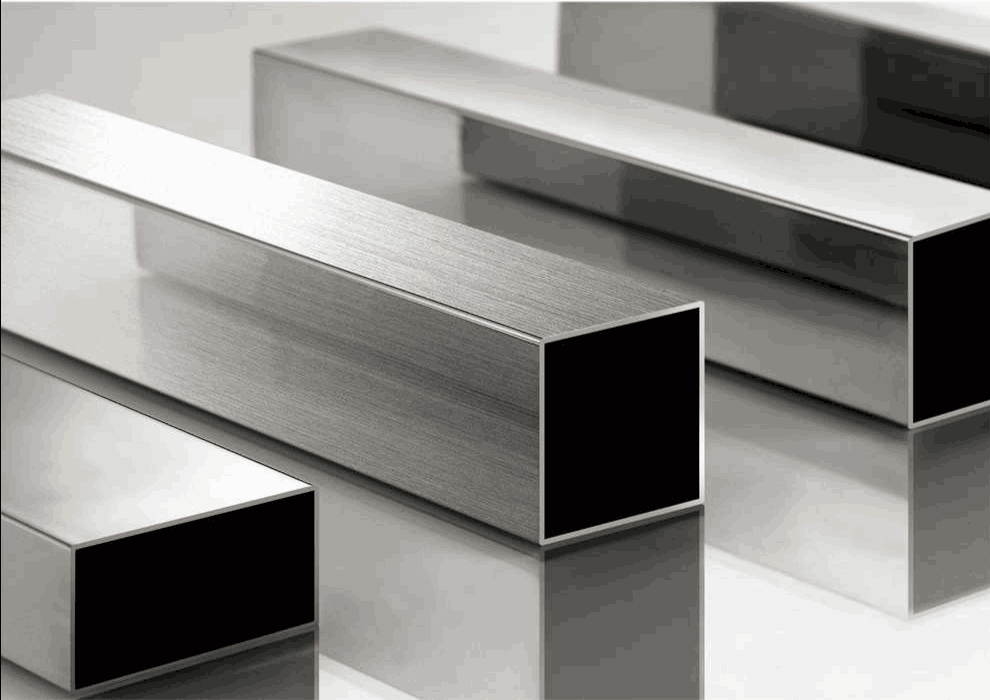

ss 201 stainless steel pipes price per kg

Material | 304:0cr18ni9, 0cr17ni8 201:1cr17mn6ni5n,1cr13mn9ni1n 316:0cr17ni12 or as customer’s request |

Size(round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 59, 168, 219 mm or customized |

Size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23, 40×20,50×20,60×15,75×45,80×60,95×45,100×60,150×100 mm or customized |

Size (oval pipe) | 30×15,80×40 mm os customized |

Thickness | 0.24-3 mm |

Length | 6m or according to customer’s request |

Outer diameter | 6.35-219mm |

Tolerance | Outer diameter :±0.2mm |

Thickness :±0.02mm | |

Length :±0.5mm | |

Process method | Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

Finishing | A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlum E : HL brushed & mirror (two kinds of finishing for one pipe) |

Chemical Composition | |||||||

Material | C | Si | Mn | P | S | Cr | Ni |

201 | ≤0.12 | ≤0.75 | 9.5-12.5 | ≤0.045 | ≤0.03 | 13-16 | 0.8-1.5 |

304 | ≤0.08 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.03 | 18-19 | 8-10 |

316 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.035 | ≤0.03 | 10-14 | 16.0-18.5 |

430 | ≤0.12 | ≤0.75 | ≤2.0 | ≤0.04 | ≤0.03 | 16-18 | ≤0.6 |

Square pipe and rectangle pipe

round pipe

PACK & DELIVERY

Packaging & Delivery of ss201stainless steel tubes price per kg

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

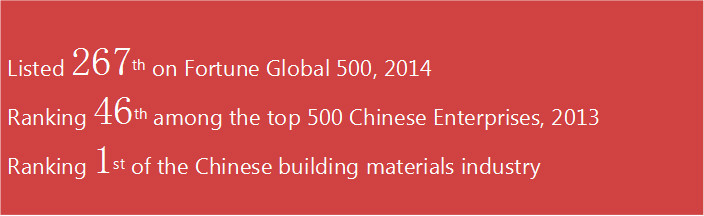

COMPANY INFORMATION

Company Information

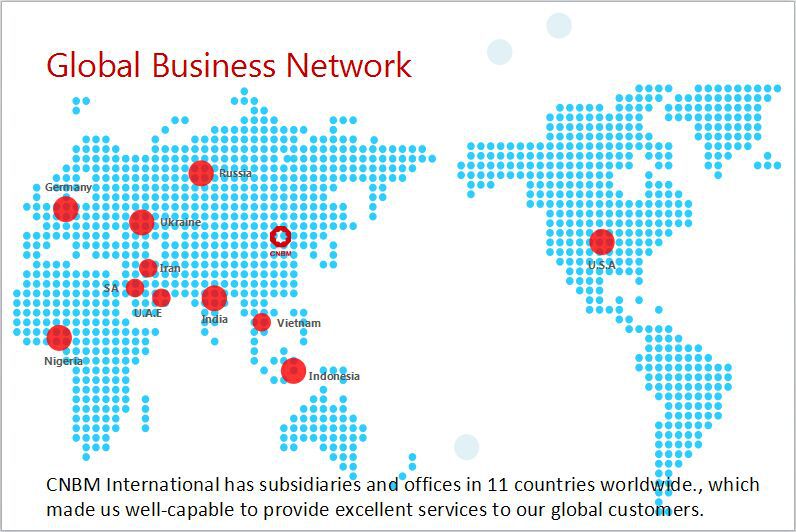

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Client

Export Markets Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

F A Q

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can stainless steel pipes be welded?

- Yes, stainless steel pipes can be welded. Stainless steel is a popular material used in various industries due to its high corrosion resistance and strength. Welding is one of the common methods used to join stainless steel pipes together. However, it is important to use the appropriate welding techniques and equipment to ensure a successful weld. Stainless steel has different grades, each with its own specific welding requirements. The welding process for stainless steel pipes typically involves using a filler material that matches the grade of stainless steel being welded. It is also crucial to properly clean and prepare the surfaces to be welded to ensure a strong and durable joint.

- Q: Can stainless steel pipes be polished?

- Yes, stainless steel pipes can be polished.

- Q: Can stainless steel pipes be used for fire sprinkler systems?

- Yes, stainless steel pipes can be used for fire sprinkler systems.

- Q: Can stainless steel pipes be used for refrigeration systems?

- Yes, stainless steel pipes can be used for refrigeration systems. Stainless steel is a highly durable material that provides excellent resistance to corrosion, making it ideal for use in refrigeration systems where moisture and low temperatures are present. Stainless steel pipes also have high thermal conductivity, allowing for efficient and effective heat transfer within the system. Additionally, stainless steel pipes are easy to clean, maintain, and can withstand high pressure, making them suitable for use in refrigeration systems that require reliable and long-lasting performance.

- Q: Are stainless steel pipes suitable for wastewater treatment facilities?

- Stainless steel pipes are a great fit for wastewater treatment facilities due to their exceptional corrosion resistance. This quality makes them perfect for managing highly corrosive wastewater. Their ability to resist chemicals and acids prevents deterioration, minimizing the chances of leaks and contamination. Moreover, stainless steel pipes are hygienic and effortless to clean, which is vital in maintaining cleanliness at wastewater treatment facilities. Furthermore, their high strength-to-weight ratio enables easy installation and reduces the necessity for extra support structures. Hence, stainless steel pipes are a dependable and long-lasting option for wastewater treatment facilities.

- Q: Can stainless steel pipes be used for wastewater treatment plants?

- Certainly! Wastewater treatment plants can utilize stainless steel pipes. Stainless steel, being remarkably durable and resistant to corrosion, proves to be an excellent selection for use in challenging settings like wastewater treatment plants. Its corrosion resistance aids in averting leaks and reducing the need for maintenance, thereby guaranteeing extended pipe longevity. Moreover, stainless steel pipes are sanitary and effortless to clean, a critical aspect in wastewater treatment plants where cleanliness and sanitation are paramount. All in all, stainless steel pipes offer a dependable and effective means of transporting wastewater within treatment plants.

- Q: Can stainless steel pipes be used for pharmaceutical industries?

- Yes, stainless steel pipes can be used for pharmaceutical industries. Stainless steel is a preferred material choice in pharmaceutical applications due to its high corrosion resistance, durability, and hygienic properties. It is commonly used for transporting pharmaceutical liquids, gases, and chemicals in a safe and sterile manner, making it suitable for pharmaceutical manufacturing and processing operations.

- Q: Are stainless steel pipes suitable for heat recovery systems?

- Yes, stainless steel pipes are suitable for heat recovery systems. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for applications involving high temperatures and aggressive environments. Heat recovery systems aim to capture and utilize waste heat from industrial processes, and stainless steel pipes can effectively handle the heat transfer process while maintaining their integrity over time. Additionally, stainless steel has excellent thermal conductivity which allows for efficient heat transfer. Therefore, using stainless steel pipes in heat recovery systems ensures optimal performance and longevity.

- Q: Can stainless steel pipes be insulated with PVC?

- Insulating stainless steel pipes with PVC is not possible. PVC, or polyvinyl chloride, is not appropriate for insulating stainless steel pipes because it cannot tolerate lower temperatures. Stainless steel pipes are commonly employed in high-temperature scenarios, and PVC insulation might become deformed or melted by the heat. It is advised to opt for insulation materials specifically created for high-temperature purposes, such as mineral wool or fiberglass, as they can offer superior thermal protection for stainless steel pipes.

- Q: Can stainless steel pipes be used for nuclear power applications?

- Yes, stainless steel pipes can be used for nuclear power applications. Stainless steel is often preferred in nuclear power plants due to its excellent corrosion resistance, high temperature resistance, and strength properties. It is resistant to oxidation and can withstand high pressure and temperatures. Stainless steel pipes are commonly used in various nuclear power plant systems such as cooling water, steam generation, and waste management systems. These pipes ensure the safe and efficient transfer of fluids and gases, maintaining the integrity and reliability of the nuclear power plant.

Send your message to us

SS 201 Stainless Steel Pipe Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords