ASTM A106/53 Stainless Steel Welded Tube manufacturer for oil Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 kg

- Supply Capability:

- 12000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A106/53:

carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

● Professional teams ensure a high efficiency of your purchase

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

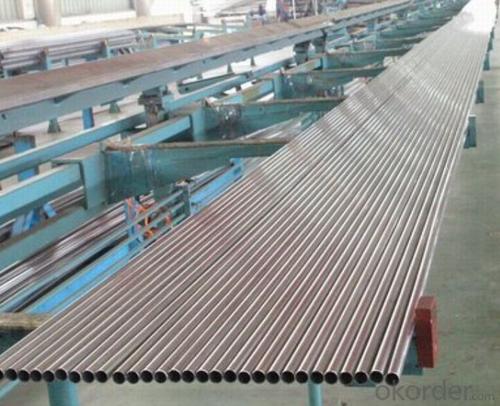

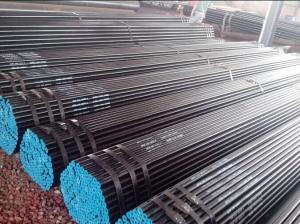

6、Seamless Pipe ASTM A106/53 Images:

- Q: Can stainless steel pipes be used for gas transportation?

- Yes, stainless steel pipes can be used for gas transportation. Stainless steel is known for its high resistance to corrosion, making it suitable for transporting various gases, including natural gas and liquefied petroleum gas (LPG). Additionally, stainless steel pipes are strong and durable, ensuring the safe and efficient transportation of gas.

- Q: Are stainless steel pipes suitable for oil and gas refineries?

- Indeed, oil and gas refineries find stainless steel pipes to be highly suitable for their operations. The exceptional corrosion resistance properties of stainless steel make it the perfect choice for handling the various corrosive substances found in these industries, such as crude oil, natural gas, and petroleum products. Moreover, stainless steel pipes exhibit resistance to high temperatures and pressures, ensuring their durability and reliability even in the harshest operating conditions of oil and gas refineries. Additionally, stainless steel pipes offer the advantage of being easy to clean and maintain, reducing the risk of contamination and minimizing the need for maintenance downtime. Therefore, due to their superior corrosion resistance, high strength, and long-term cost-effectiveness, stainless steel pipes enjoy widespread use in oil and gas refineries.

- Q: Can stainless steel pipes be used for hygienic applications?

- Yes, stainless steel pipes can be used for hygienic applications. Stainless steel is a popular choice for hygienic environments due to its corrosion resistance, durability, and ease of cleaning. It is commonly used in industries such as food processing, pharmaceuticals, and medical facilities where cleanliness and sanitation are crucial.

- Q: Are stainless steel pipes suitable for pharmaceutical industries?

- Yes, stainless steel pipes are highly suitable for pharmaceutical industries. Stainless steel is known for its excellent corrosion resistance and ability to withstand high temperatures and pressure. These qualities make it ideal for pharmaceutical applications, where maintaining product purity and preventing contamination are critical. Stainless steel pipes are non-reactive, meaning they do not interact with the pharmaceutical products being transported, ensuring the integrity and safety of the drugs. They are also easy to clean and sanitize, making them suitable for applications that require frequent cleaning, such as pharmaceutical manufacturing processes. Furthermore, stainless steel pipes comply with the stringent regulations and standards set by pharmaceutical authorities, ensuring that the industry's quality and safety requirements are met. They can be customized to meet specific needs, such as different sizes, shapes, and wall thicknesses, allowing for flexibility in design and installation. Overall, stainless steel pipes offer numerous advantages for pharmaceutical industries, including durability, resistance to corrosion and contamination, ease of cleaning, and compliance with industry standards.

- Q: What does "stainless steel pipe" DN mean?

- Nominal diameter is the size of all piping accessories in the piping system. The nominal diameter is a convenient round integer for reference and is not strictly related to the processing size. The nominal diameter follows the letter "DN" followed by a number sign.

- Q: What is the maximum temperature for stainless steel pipes?

- The maximum temperature for stainless steel pipes can vary depending on the specific grade of stainless steel being used. However, in general, stainless steel pipes can typically withstand temperatures ranging from 1000 to 1600 degrees Fahrenheit (537 to 871 degrees Celsius).

- Q: Are stainless steel pipes suitable for hydraulic applications?

- Yes, stainless steel pipes are suitable for hydraulic applications. They offer excellent corrosion resistance and durability, making them ideal for use in hydraulic systems where fluid flow and pressure are involved. Additionally, stainless steel pipes can handle high temperatures and are resistant to cracking, making them a reliable choice for hydraulic applications.

- Q: Can stainless steel pipes be used for automotive applications?

- Stainless steel pipes are suitable for automotive applications, offering exceptional resistance to corrosion and heat. Because of this, they are an excellent option for automobiles in challenging environments, such as those with high temperatures, moisture, and road salt. Stainless steel pipes are frequently utilized in exhaust systems, fuel lines, and other vehicle components. Compared to other materials, they possess superior strength and durability, resulting in longer-lasting automotive parts and decreased necessity for frequent replacements. Furthermore, stainless steel pipes have a pleasing appearance and can be readily customized to meet precise design specifications for automotive use.

- Q: Are stainless steel pipes suitable for wastewater pumping stations?

- Yes, stainless steel pipes are suitable for wastewater pumping stations. Stainless steel is a highly corrosion-resistant material, making it particularly well-suited for environments with high levels of moisture and chemicals, such as wastewater pumping stations. It is resistant to rust and can withstand the corrosive nature of wastewater, which can contain various chemicals and contaminants. Stainless steel pipes also have high strength and durability, enabling them to handle the pressure and flow requirements of wastewater pumping systems. Additionally, stainless steel pipes offer a smooth interior surface, which helps to minimize friction and improve the efficiency of water flow. Overall, stainless steel pipes are an excellent choice for wastewater pumping stations due to their corrosion resistance, strength, and durability.

- Q: What is the difference between Schedule 5 and Schedule 10 stainless steel pipes?

- Schedule 5 and Schedule 10 stainless steel pipes find frequent use across various industries and applications, though they possess distinct dissimilarities. The primary disparity resides within their wall thickness. While Schedule 5 stainless steel pipes boast a slimmer wall thickness, Schedule 10 stainless steel pipes possess a thicker wall. Consequently, Schedule 5 pipes exhibit a greater internal diameter, facilitating a more substantial flow of fluids or gases through the conduit. On the contrary, Schedule 10 stainless steel pipes exhibit a reduced internal diameter due to their thicker walls. This renders them more suitable for applications necessitating higher pressure or strength, as the heightened wall thickness grants augmented durability and resistance against external forces. Moreover, the disparate wall thicknesses of Schedule 5 and Schedule 10 pipes influence their weight and cost. Owing to their thinner walls, Schedule 5 pipes weigh less and command a lower price than Schedule 10 pipes. Concerning availability, Schedule 10 stainless steel pipes witness more frequent usage in industrial processes involving high pressure or corrosive environments, such as chemical plants or oil refineries. Conversely, Schedule 5 stainless steel pipes are often employed in applications where the flow of fluids or gases does not encounter extreme pressure, such as plumbing or low-pressure conveying systems. In summary, the principal distinctions between Schedule 5 and Schedule 10 stainless steel pipes lie within their wall thickness, internal diameter, strength, weight, and cost. The choice between the two hinges upon the specific requirements of the application and the level of pressure or durability required.

Send your message to us

ASTM A106/53 Stainless Steel Welded Tube manufacturer for oil Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 kg

- Supply Capability:

- 12000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords