seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:60.3*3.91 mm or others

2.Surface: NO.1

3.Length:6m or as your requirement

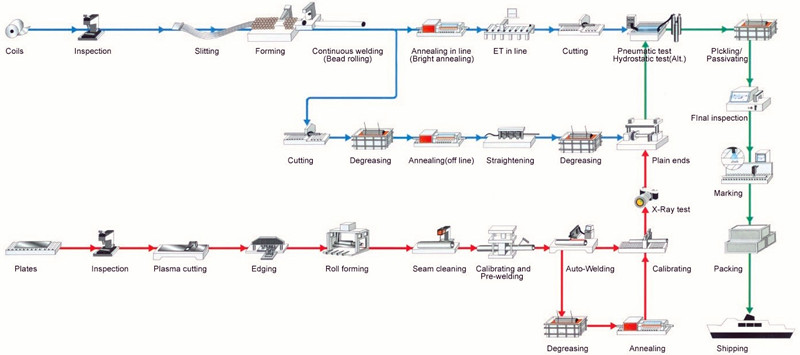

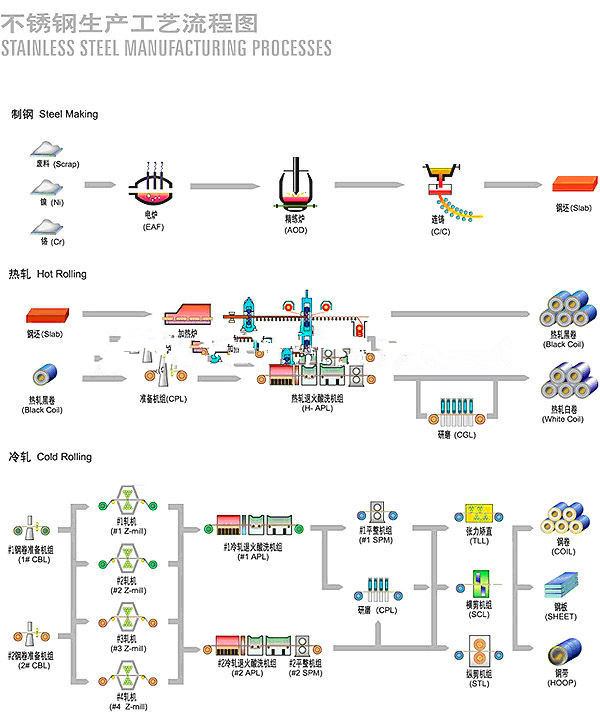

A series of photos

A series of pictures

- Q: Can stainless steel pipes be used for hygienic applications?

- Indeed, hygienic applications can utilize stainless steel pipes. In industries such as food and beverage, pharmaceuticals, and biotechnology, where cleanliness is paramount, stainless steel is a highly durable and corrosion-resistant material commonly employed. The smooth surface of stainless steel pipes hinders the growth of bacteria and other microorganisms, making them an appropriate choice for applications that require cleanliness. Furthermore, their smooth surface facilitates easy and thorough cleaning, thereby minimizing the risk of contamination. Furthermore, stainless steel pipes do not react with substances and do not release any harmful materials into the products being transported. This characteristic makes them particularly suitable for applications that demand sanitary conditions, such as in the production and transportation of food, beverages, and pharmaceuticals. Additionally, stainless steel pipes exhibit exceptional resistance to high temperatures, chemicals, and corrosion, thereby guaranteeing the integrity of the system and preventing any contamination or leaks. They are also highly durable and can withstand harsh operating conditions, making them a dependable option for hygienic applications. To summarize, stainless steel pipes possess the necessary attributes, including durability, corrosion resistance, smooth surface, ease of cleaning, and non-reactivity, to cater to hygienic applications. They offer a reliable and sanitary solution for industries that prioritize hygiene.

- Q: What is the difference between stainless steel pipes and carbon steel pipes?

- Stainless steel pipes and carbon steel pipes differ in their composition, properties, and applications. Composition: Stainless steel pipes are made primarily from an alloy of iron, chromium, and sometimes nickel. This composition gives stainless steel its corrosion-resistant properties. On the other hand, carbon steel pipes are made primarily from an alloy of iron and carbon. The carbon content in carbon steel pipes can range from 0.1% to 2.1%, which affects the strength and hardness of the material. Properties: Stainless steel pipes have excellent corrosion resistance, making them ideal for applications where the pipes will be exposed to moisture, chemicals, or other corrosive substances. They are also highly resistant to heat and can withstand high-pressure environments. Carbon steel pipes, on the other hand, are not as resistant to corrosion and are more susceptible to rust. However, they are stronger and more durable than stainless steel pipes, making them suitable for high-stress applications. Applications: Due to their corrosion resistance, stainless steel pipes are commonly used in industries such as food processing, pharmaceuticals, chemical processing, and marine applications. They are also widely used in plumbing, HVAC systems, and construction. Carbon steel pipes, with their higher strength and durability, are commonly used in oil and gas pipelines, structural applications, and machinery manufacturing. In summary, the main difference between stainless steel pipes and carbon steel pipes lies in their composition and properties. Stainless steel pipes are corrosion-resistant and heat-resistant, while carbon steel pipes are stronger and more durable. The choice between the two depends on the specific requirements of the application, such as the need for corrosion resistance, strength, or cost-effectiveness.

- Q: What are the different types of stainless steel pipes available?

- There are several different types of stainless steel pipes available, each with their own unique properties and uses. 1. Austenitic stainless steel pipes: This type of stainless steel is the most common and versatile. It contains high levels of chromium and nickel, making it highly resistant to corrosion and oxidation. Austenitic stainless steel pipes are widely used in various industries, including construction, automotive, and food processing. 2. Ferritic stainless steel pipes: Ferritic stainless steel contains high levels of chromium but low levels of carbon, which gives it excellent resistance to corrosion. These pipes are commonly used in applications where high strength and resistance to stress corrosion cracking are required. 3. Martensitic stainless steel pipes: Martensitic stainless steel is known for its high strength and hardness. These pipes are often used in applications that require resistance to wear and abrasion, such as cutlery, tools, and bearings. 4. Duplex stainless steel pipes: Duplex stainless steel is a combination of austenitic and ferritic stainless steels. This type of steel offers excellent corrosion resistance and high strength. Duplex stainless steel pipes are commonly used in industries that require resistance to chloride stress corrosion cracking, such as offshore oil and gas production. 5. Precipitation-hardening stainless steel pipes: Precipitation-hardening stainless steel pipes are heat-treatable and have high strength and corrosion resistance. They are often used in industries such as aerospace and chemical processing, where both strength and resistance to corrosion are essential. These are just a few examples of the different types of stainless steel pipes available. The choice of the right type of stainless steel pipe depends on the specific application and the required properties, such as corrosion resistance, strength, and temperature resistance.

- Q: Can stainless steel pipes be used for solar power systems?

- Yes, stainless steel pipes can be used for solar power systems. Stainless steel is a commonly used material in solar power systems due to its durability, corrosion resistance, and high temperature tolerance. It is often used for the construction of solar water heaters, solar thermal collectors, and solar panel frames.

- Q: Can stainless steel pipes be used for swimming pool installations?

- Yes, stainless steel pipes can be used for swimming pool installations. Stainless steel is highly resistant to corrosion and can withstand the harsh chemicals used in pool water. It is also durable, long-lasting, and can handle high water pressure.

- Q: Can stainless steel pipes be etched?

- Stainless steel pipes have the capability to undergo etching, a procedure which involves eliminating a thin layer of metal from the pipe's surface to achieve a desired design or pattern. This is typically accomplished by utilizing an acid or chemical solution that selectively dissolves the exposed metal. However, it is worth mentioning that not all grades of stainless steel are equally suitable for etching. Austenitic stainless steels, specifically 304 and 316, are frequently chosen for etching purposes due to their corrosion resistance and ease of etching. The etching process can also be influenced by various factors, including the composition and thickness of the stainless steel, as well as the chosen method and conditions for etching.

- Q: Can stainless steel pipes be coated or painted?

- Yes, stainless steel pipes can be coated or painted. Coating or painting stainless steel pipes can provide various benefits such as enhanced corrosion resistance, improved aesthetic appearance, and increased durability. However, it is important to note that proper surface preparation is crucial before applying any coating or paint to ensure adhesion and longevity. Additionally, it is recommended to use coatings or paints specifically designed for stainless steel to maintain its inherent qualities and prevent any potential issues such as flaking or peeling.

- Q: Can stainless steel pipes be used for power generation?

- Yes, stainless steel pipes can be used for power generation. Stainless steel is a highly versatile and durable material that is commonly used in various industries, including power generation. It offers excellent corrosion resistance, high strength, and heat resistance, making it suitable for applications involving high temperatures and pressures. In power generation, stainless steel pipes are often used in the construction of power plants, including fossil fuel-fired plants, nuclear power plants, and renewable energy facilities. They are used for transporting various fluids, such as steam, water, and fuel, within the power generation system. Stainless steel pipes are particularly beneficial in power generation due to their ability to withstand extreme conditions, including high temperatures and corrosive environments. They provide excellent resistance against corrosion, which helps to maintain the integrity and longevity of the pipes, ensuring the continuous and reliable operation of power generation systems. Furthermore, stainless steel pipes are highly resistant to thermal expansion and contraction, which is crucial in power generation applications that involve frequent temperature changes. This characteristic helps to prevent leaks and maintain the overall efficiency of the power generation process. In conclusion, stainless steel pipes are widely used in power generation due to their excellent corrosion resistance, high strength, and ability to withstand extreme conditions. They play a vital role in transporting fluids within power plants and contribute to the overall efficiency and reliability of power generation systems.

- Q: Can stainless steel pipes be used for nuclear power applications?

- Yes, stainless steel pipes can be used for nuclear power applications. Stainless steel is known for its corrosion resistance, high strength, and ability to withstand high temperatures, making it suitable for various demanding environments, including nuclear power plants. Additionally, stainless steel's low reactivity with nuclear materials and its ability to maintain structural integrity under radiation exposure further make it a preferred choice for nuclear power applications.

- Q: How are stainless steel pipes insulated?

- To ensure thermal efficiency and prevent heat loss or condensation, stainless steel pipes are commonly insulated using a variety of methods. One method involves wrapping insulation materials like mineral wool or fiberglass around the pipes and securing them with a metal jacket. This insulation material helps reduce heat transfer and maintains the desired temperature of the fluid inside the pipe. Another option is to apply foam insulation directly to the pipe's surface and then cover it with a protective layer like a PVC jacket. This type of insulation forms a seamless and moisture-resistant barrier, effectively preventing any heat loss or condensation. In some cases, stainless steel pipes are insulated through a process known as "cladding." This involves applying a layer of insulating material, such as aluminum or stainless steel, to the exterior surface of the pipe. Cladding provides additional protection against external elements and helps maintain the desired temperature within the pipe. Insulating stainless steel pipes is crucial in various industries where temperature control is vital, such as oil and gas, chemical processing, or HVAC systems. The choice of insulation method depends on factors like the specific application, desired temperature range, and environmental conditions surrounding the pipe.

Send your message to us

seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords