Schuco Aluminum Profiles for Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

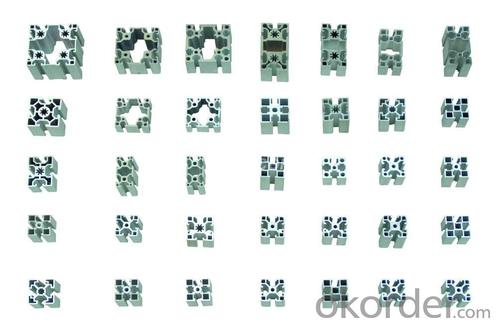

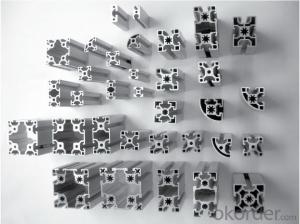

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Can aluminum profiles be used for creating protective enclosures?

- Yes, aluminum profiles can be used for creating protective enclosures. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various applications, including protective enclosures. Aluminum profiles can be easily fabricated and assembled to create custom enclosures of different shapes and sizes. They provide excellent structural integrity and can withstand harsh environmental conditions. Additionally, aluminum profiles offer good thermal conductivity, allowing for efficient heat dissipation if required. Overall, aluminum profiles are a popular choice for creating protective enclosures due to their versatility, strength, and durability.

- Q: This question asks for methods to protect aluminum profiles from water damage during the installation and usage phases.

- <p>To prevent water damage to aluminum profiles during installation or use, follow these steps: 1. Ensure the aluminum profiles are properly sealed with a high-quality sealant to prevent water penetration. 2. Use corrosion-resistant fasteners and hardware to avoid rusting. 3. Install drainage systems to direct water away from the profiles. 4. Regularly inspect and maintain the profiles to identify and repair any damage promptly. 5. Avoid installing profiles in areas with high humidity or direct exposure to rain. 6. Use protective coatings or paints that are water-resistant and compatible with aluminum. 7. Keep the profiles clean and free from dirt or debris that can trap moisture. By following these precautions, you can significantly reduce the risk of water damage to aluminum profiles.</p>

- Q: Are aluminum profiles suitable for lighting fixtures?

- Lighting fixtures can greatly benefit from the use of aluminum profiles. Aluminum, being a lightweight and versatile material, offers numerous advantages for lighting applications. To begin with, aluminum profiles possess excellent thermal conductivity. This means they effectively dissipate the heat generated by the lighting fixtures. Maintaining a cooler operating temperature is crucial as excessive heat can shorten the lifespan and impact the performance of the lighting components. By utilizing aluminum profiles, the longevity and efficiency of the lighting fixtures are enhanced. Moreover, aluminum profiles are resistant to corrosion, making them suitable for both indoor and outdoor lighting fixtures. This corrosion resistance ensures that the fixtures can endure harsh environmental conditions, such as high humidity or moisture exposure, without deteriorating or losing functionality. Additionally, aluminum profiles are easily customizable and can be tailored to meet various lighting requirements. They can be extruded into different shapes and sizes, allowing for flexibility in the design of lighting fixtures. This versatility empowers manufacturers to create sleek and modern lighting solutions that seamlessly integrate into different architectural designs and spaces. Furthermore, aluminum profiles offer aesthetic appeal as they can be powder-coated or anodized in a wide array of colors. This provides a plethora of options to match different interior or exterior design themes. Lastly, aluminum is a sustainable material that can be fully recycled. By choosing aluminum profiles for lighting fixtures, one contributes to reducing environmental impact and supports the principles of sustainability. To summarize, aluminum profiles are highly suitable for lighting fixtures due to their thermal conductivity, corrosion resistance, versatility, aesthetic appeal, and sustainability. This is why they are extensively used in the lighting industry.

- Q: What are the advantages of using aluminum profiles in the renewable energy sector?

- The utilization of aluminum profiles in the renewable energy sector brings forth numerous benefits. To begin with, these profiles possess a combination of lightness and strength, rendering them ideal for the construction of solar panel frames, wind turbine components, and other renewable energy infrastructure. Their favorable strength-to-weight ratio facilitates easy transportation and installation, thereby reducing costs and enhancing efficiency. Moreover, aluminum profiles exhibit exceptional resistance to corrosion, making them suitable for outdoor applications, even in harsh environments. This durability ensures the stability and functionality of renewable energy infrastructure over extended periods, including coastal areas and corrosive surroundings. Furthermore, aluminum profiles offer remarkable thermal conductivity, a crucial attribute for efficient heat dissipation in renewable energy systems. This property facilitates efficient cooling of solar panels, wind turbine generators, and other components, thereby improving their performance and lifespan. Additionally, aluminum is a sustainable material that can be effortlessly recycled. With the renewable energy sector's focus on promoting sustainability, the utilization of aluminum profiles aligns perfectly with the industry's objectives. Aluminum can be recycled repeatedly without compromising its properties, reducing the need for primary aluminum production and minimizing the carbon footprint of renewable energy projects. Lastly, aluminum profiles provide design flexibility and versatility. They can be easily customized and fabricated into various shapes and sizes, allowing for seamless integration into different renewable energy applications. This adaptability empowers engineers and designers to optimize the use of aluminum profiles, resulting in improved energy efficiency and overall system performance. In conclusion, the utilization of aluminum profiles in the renewable energy sector offers advantages such as lightweight strength, corrosion resistance, thermal conductivity, sustainability, and design flexibility. By incorporating aluminum profiles into renewable energy infrastructure, we can enhance the efficiency, durability, and environmental sustainability of the sector.

- Q: What is the maximum length of aluminum profiles available?

- The maximum length of aluminum profiles available can vary depending on the supplier and specific requirements, but it is typically around 6 meters (20 feet).

- Q: How do you prevent galvanic corrosion with aluminum profiles?

- To prevent galvanic corrosion with aluminum profiles, several measures can be taken. Firstly, it is essential to ensure that the aluminum profiles are not in direct contact with dissimilar metals, especially those that have a higher electrochemical potential. This can be achieved by using insulating materials, coatings, or gaskets between the aluminum profiles and other metals. Additionally, applying protective coatings or anodizing the aluminum surfaces can provide a barrier against corrosion. Regular maintenance, including cleaning and inspection, is also crucial to identify any potential corrosion risks and address them promptly.

- Q: The latest list of aluminum China

- Lear aluminum is also good Oh, A Well-Known Trademark in China, China energy-saving innovation enterprise ten, Hebei enterprises in Handan

- Q: When will the aluminum mold be padded?

- The plane will die pad is a small pad on the inside of the die sleeve, and a large pad size is the size of the inner diameter of the sliding seat, there are generally several square and circular pad, some special structure material need professional pad, such as an open slot, the structure is not very stable, when die under high pressure are squashed requires a special pad.

- Q: Can aluminum profiles be used in roofing systems?

- Yes, aluminum profiles can be used in roofing systems. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an ideal choice for roofing applications. Aluminum profiles can be used to create various roofing components, such as gutters, downspouts, and flashing, which help to channel water away from the roof and prevent leaks. Additionally, aluminum profiles can be easily fabricated and customized to fit the specific requirements of a roofing system. Overall, aluminum profiles offer numerous advantages for roofing systems, including strength, durability, and resistance to weathering, making them a popular choice for both residential and commercial roofing projects.

- Q: How about the price of aluminum profile?

- Usually calculated by weight, or by weight according to the length of each metre.

Send your message to us

Schuco Aluminum Profiles for Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords