SBS Membrane Self-Adhesive Sticky for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SBS MembraneSelf-Adhesive Sticky for Waterproof System

Description Of SBS Membrane Self-Adhesive Sticky:

1. SBS membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. SBS membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. SBS membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of SBS Membrane Self-Adhesive Sticky:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of SBS Membrane Self-Adhesive Sticky:

Material | SBS modified asphalt impregnated and coated tire base |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Self-Adhesive Sticky |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of SBS Membrane Self-Adhesive Sticky:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

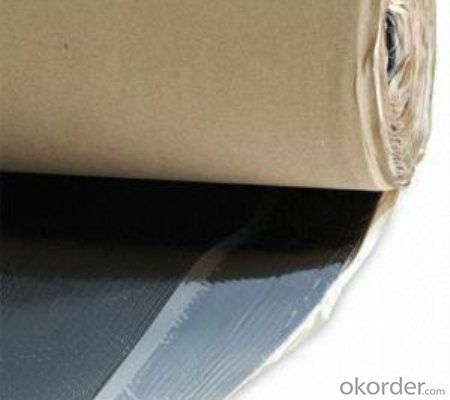

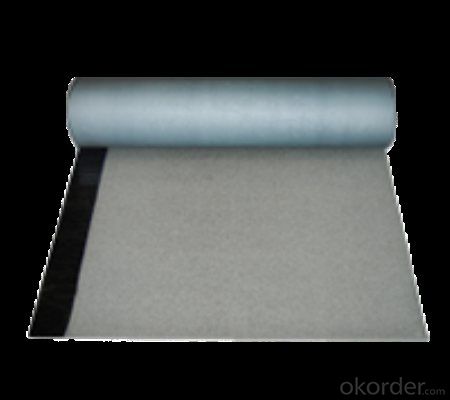

IMages of SBS Self-Adhesive Sticky Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Are there any specific installation requirements for waterproofing membranes?

- Yes, there are specific installation requirements for waterproofing membranes. These requirements may vary depending on the type of membrane being used, but there are some general guidelines that apply to most installations. Firstly, it is important to properly prepare the surface that the membrane will be applied to. This may involve cleaning the surface, removing any loose debris or previous coatings, and ensuring the surface is smooth and free from any irregularities. This step is crucial as it allows for better adhesion between the membrane and the surface. Next, the membrane should be applied according to the manufacturer's instructions. This typically involves using a suitable adhesive or bonding agent to adhere the membrane to the surface. It is important to follow the recommended application rate and ensure that the membrane is applied evenly and without any air bubbles or wrinkles. In addition to proper application, it is also important to pay attention to the seams and joints of the membrane. These areas are particularly vulnerable to water penetration, so they should be carefully sealed using an appropriate sealant or tape. This ensures a watertight seal and prevents any water from seeping through the seams. Lastly, it is important to protect the installed membrane from any damage during and after installation. This may involve covering the membrane with a protective layer, such as a geotextile fabric or a layer of soil, to prevent punctures or tears. Additionally, any construction or landscaping work that may occur after the installation should be done with caution to avoid damaging the membrane. Overall, the specific installation requirements for waterproofing membranes will depend on the type of membrane being used and the specific conditions of the project. It is always recommended to consult the manufacturer's instructions and guidelines to ensure proper installation and long-lasting waterproofing performance.

- Q: Can a waterproofing membrane be used on retaining walls?

- Yes, a waterproofing membrane can be used on retaining walls. Retaining walls are often exposed to moisture and hydrostatic pressure, which can lead to water infiltration and deterioration of the structure. Applying a waterproofing membrane on the retaining wall can help prevent water penetration, protect the wall from moisture-related damage, and prolong its lifespan. The membrane acts as a barrier, preventing water from seeping into the wall and causing potential issues such as efflorescence, cracks, or erosion. It is important to choose a waterproofing membrane that is specifically designed for below-grade applications and is capable of withstanding the pressure exerted by the retained soil. Additionally, proper installation techniques and appropriate drainage systems should be considered to ensure the effectiveness of the waterproofing membrane on retaining walls.

- Q: Can waterproofing membranes be used on parking decks?

- Yes, waterproofing membranes can be used on parking decks. Parking decks are exposed to various weather conditions and are subject to constant vehicle traffic, which can lead to water penetration and damage. Waterproofing membranes provide a protective barrier against water infiltration, preventing moisture from seeping into the structure and causing deterioration. These membranes are designed to withstand heavy loads and resist the chemicals found in automotive fluids, making them an ideal solution for parking decks. By applying waterproofing membranes, the lifespan of the parking deck can be extended, reducing the need for costly repairs and ensuring the safety and integrity of the structure.

- Q: Does a waterproofing membrane prevent mold and mildew growth?

- Yes, a waterproofing membrane can help prevent mold and mildew growth by creating a barrier that prevents moisture from seeping into walls, floors, or other surfaces. By keeping the area dry, it reduces the conditions necessary for mold and mildew to thrive. However, it is important to note that a waterproofing membrane alone may not completely eliminate mold and mildew, as proper ventilation and maintenance are also crucial in preventing their growth.

- Q: Can a waterproofing membrane be used for a stadium roof?

- Yes, a waterproofing membrane can be used for a stadium roof. Waterproofing membranes are commonly used in construction projects, including roofs, to prevent water infiltration and protect the underlying structure from water damage. The membrane acts as a barrier against moisture and is designed to withstand the harsh outdoor elements, such as rain, snow, and UV radiation. By applying a waterproofing membrane to a stadium roof, it can help ensure that the roof remains watertight and prevents leaks, which is crucial for maintaining the integrity of the stadium and protecting spectators, equipment, and facilities inside. Additionally, waterproofing membranes are available in various types and materials, allowing for customization to meet the specific requirements and design of the stadium roof.

- Q: Can waterproofing membranes be used on rooftop terraces?

- Yes, waterproofing membranes can be used on rooftop terraces to protect them from water damage and ensure their longevity.

- Q: Are waterproofing membranes resistant to saltwater corrosion?

- Yes, waterproofing membranes are generally resistant to saltwater corrosion. They are designed to withstand harsh environmental conditions, including exposure to saltwater, without deteriorating or being affected by corrosion.

- Q: Can a waterproofing membrane be used in historic buildings?

- Yes, a waterproofing membrane can be used in historic buildings. Historic buildings often face challenges related to moisture infiltration and water damage due to their age and construction materials. Waterproofing membranes are a common solution to prevent water seepage and protect the building's structural integrity. However, it is important to choose a waterproofing membrane that is compatible with the historic building's materials and construction methods to ensure its preservation and adherence to historical authenticity. Additionally, any waterproofing work done on a historic building should be carried out by professionals with expertise in historic preservation to ensure proper installation and minimal impact on the building's historical value.

- Q: Are waterproofing membranes UV resistant?

- Indeed, the majority of waterproofing membranes boast UV resistance. Given their frequent exposure to sunlight, UV resistance is a crucial attribute for these membranes. Over time, the degradation and deterioration caused by UV rays can significantly impair the effectiveness and durability of materials, necessitating the inclusion of UV-resistant additives or coatings by manufacturers. This incorporation of UV resistance safeguards the integrity and performance of the membrane, guaranteeing enduring protection against water infiltration.

- Q: Can a waterproofing membrane reduce noise transmission?

- Yes, a waterproofing membrane can reduce noise transmission.

Send your message to us

SBS Membrane Self-Adhesive Sticky for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords