SBS Membrane Smooth and Non- Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SBS Membrane Smooth and Non- Smooth for Waterproof System

Description Of SBS Membrane Smooth and Non- Smooth for Waterproof System

1. SBS Membrane Smooth is made from Thermoplastic polyethylene hydrocarbons , which is for waterproofing of exposed and non-exposed applications.

2. SBS Membrane Smooth adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. SBS Membrane Smooth is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of SSBS Membrane Smooth and Non- Smooth for Waterproof System

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

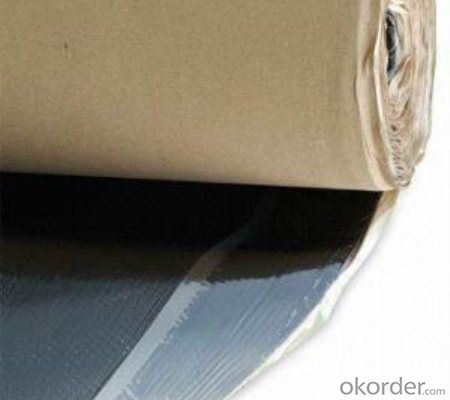

Material | SBS modified asphalt impregnated and coated tire base |

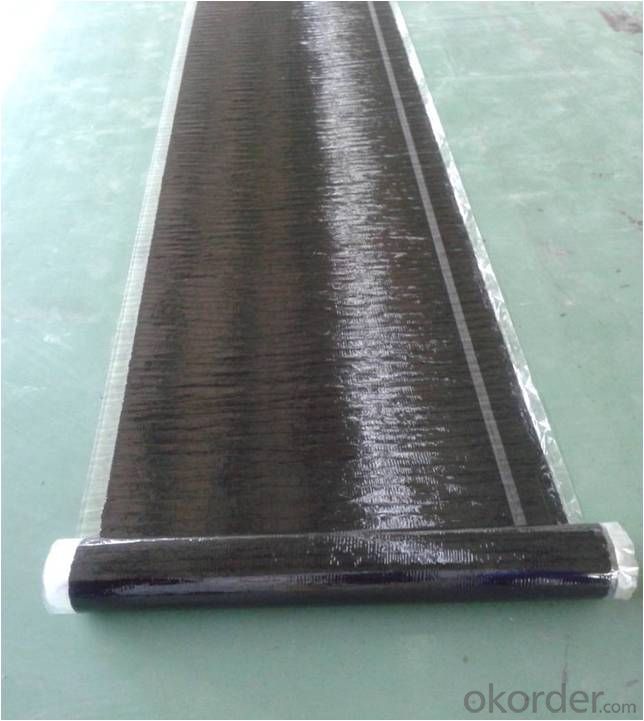

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m |

Thick | 1.2mm, 1.5mm, |

Type | Smooth and Non- Smooth |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of SBS Membrane Smooth and Non- Smooth for Waterproof System

1.Roofs, Basement

2. Industrial and civil building waterproofing

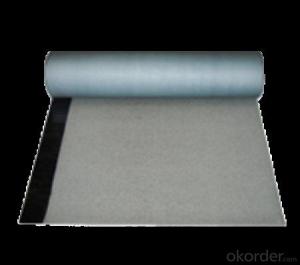

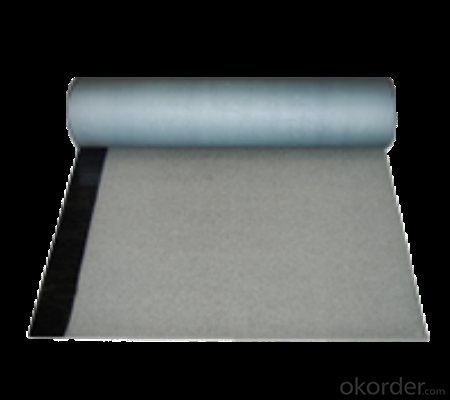

IMages of SBS Membrane Smooth and Non- Smooth for Waterproof System

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 12 years.

3. How long do we usually reply your request?

We always reply our customer within 4 hours.

- Q: Does a waterproofing membrane prevent efflorescence or mineral deposits on surfaces?

- Efflorescence or mineral deposits on surfaces can be prevented with the use of a waterproofing membrane. Efflorescence occurs when water-soluble salts dissolve in concrete or masonry materials and migrate to the surface, leaving behind a white residue. By stopping water from penetrating the surface, a waterproofing membrane reduces the amount of water available to dissolve these salts and carry them to the surface, effectively reducing the occurrence of efflorescence. Similarly, mineral deposits can form when water with dissolved minerals evaporates, leaving behind the minerals as residue. A waterproofing membrane prevents water from reaching the surface, thus minimizing the formation of mineral deposits. It is important to note, however, that a waterproofing membrane may not completely eliminate these issues if there are underlying problems with the material or water source. To ensure the effectiveness of the waterproofing membrane in preventing efflorescence or mineral deposits, regular maintenance and proper installation are crucial.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is typically resistant to hydrocarbons or oil spills. Waterproofing membranes are designed to create a barrier that prevents water penetration and moisture damage to the underlying surfaces. These membranes are often made from materials such as modified bitumen, polyurethane, or PVC, which have excellent resistance to various chemicals, including hydrocarbons and oil. This resistance ensures that the membrane remains intact and effective even when exposed to oil spills or hydrocarbon-based substances. However, it is essential to note that the specific resistance may vary depending on the type and quality of the waterproofing membrane used. Therefore, it is crucial to select a membrane that is specifically engineered to withstand the intended environment and potential chemical exposures.

- Q: Can a waterproofing membrane be installed on a sloping surface?

- Yes, a waterproofing membrane can be installed on a sloping surface. In fact, it is often necessary to install a waterproofing membrane on sloping surfaces to ensure proper water drainage and prevent water seepage.

- Q: Can a waterproofing membrane be used on brick walls?

- Yes, a waterproofing membrane can be used on brick walls. Brick is a porous material that can absorb water and moisture, making it susceptible to damage and deterioration over time. Applying a waterproofing membrane on brick walls helps to prevent water penetration and protect the structural integrity of the bricks. The membrane acts as a barrier, preventing water from seeping into the bricks while still allowing moisture to evaporate. This helps to keep the bricks dry and reduces the risk of water-related issues such as efflorescence, mold, and mildew. Additionally, a waterproofing membrane can also enhance the thermal insulation properties of the brick walls by reducing heat loss and improving energy efficiency. It is important to choose a waterproofing membrane specifically designed for use on masonry surfaces to ensure proper adhesion and long-lasting protection.

- Q: Can a waterproofing membrane be used in areas with heavy foot traffic or vehicle loadings?

- In high-traffic or heavy loading areas, it is possible to utilize a waterproofing membrane. Nevertheless, it is crucial to select a membrane specifically designed for such purposes in order to guarantee durability and longevity. These specialized membranes are typically thicker and more resistant to wear and tear. Furthermore, it is important to consider the type of traffic or loading that the area will endure. For instance, areas with vehicular traffic may necessitate a membrane with higher compressive strength to endure the weight of vehicles. In conclusion, the selection of the appropriate type of membrane that satisfies the specific demands of the application is of utmost importance when using waterproofing membranes in high-traffic or heavy loading areas.

- Q: Can a waterproofing membrane be used for interior applications?

- Yes, a waterproofing membrane can be used for interior applications. It is commonly used in bathrooms, kitchens, basements, and other areas where moisture or water damage is a concern. The membrane helps prevent water penetration and protects the underlying structure from potential damage.

- Q: How does a waterproofing membrane handle joint movement?

- To prevent water infiltration and maintain its effectiveness, a waterproofing membrane is specially crafted to handle joint movement. It accomplishes this by exhibiting flexibility and the ability to adapt to the expansion and contraction of joints. When joints experience movement due to factors like temperature fluctuations or settling of the structure, a waterproofing membrane must have the capability to stretch and compress without tearing or compromising its waterproofing properties. This is typically achieved through the utilization of elastomeric materials, such as rubber or synthetic polymers, which boast exceptional elongation and recovery properties. Moreover, waterproofing membranes may incorporate reinforcing materials, such as fabric or mesh, to enhance their tensile strength and their capacity to withstand joint movement. These reinforcements assist in distributing the stresses caused by joint movement, thus preventing localized damage and preserving the integrity of the membrane. Furthermore, certain waterproofing membranes possess special adhesive properties that enable them to tightly bond to the surfaces they are applied to, including the edges of joints. This adhesive bond plays a crucial role in establishing a continuous barrier against water penetration, even in the presence of joint movement. In summary, a waterproofing membrane is designed to exhibit flexibility and durability, ensuring effective management of joint movement, long-term protection against water intrusion, and the preservation of the structural integrity of the building or structure.

- Q: Is a waterproofing membrane resistant to abrasion?

- Yes, a waterproofing membrane is generally resistant to abrasion. Waterproofing membranes are designed to provide a protective barrier against water and moisture intrusion. They are typically made from durable materials such as PVC, TPO, or EPDM, which have high resistance to abrasion. This allows them to withstand the normal wear and tear that may occur during installation or due to foot traffic or other mechanical activities. However, it is important to note that the level of abrasion resistance can vary depending on the specific type and quality of the membrane, as well as the conditions in which it is installed or used. Therefore, it is always recommended to consult the manufacturer's guidelines and specifications to ensure proper selection and installation of a waterproofing membrane.

- Q: Can a waterproofing membrane be applied in cold weather or during winter months?

- Yes, a waterproofing membrane can be applied in cold weather or during winter months. However, there are specific considerations and precautions that need to be taken into account. It is important to choose a waterproofing membrane that is specifically designed for cold weather applications. These membranes are formulated to withstand low temperatures and provide effective waterproofing even in freezing conditions. Before applying the membrane, the surface should be thoroughly cleaned and free from any debris, ice, or snow. It is also crucial to ensure that the surface is dry, as moisture can affect the adhesion and performance of the membrane. In cold weather, it may take longer for the surface to dry, so extra time should be allowed for this process. Additionally, the ambient temperature during the application should be within the recommended range specified by the manufacturer. Cold temperatures can affect the curing time of the membrane and may require longer curing periods. It is important to follow the manufacturer's instructions and guidelines for application and curing to ensure proper performance. Moreover, it is advisable to consult with a professional waterproofing contractor who has experience working in cold weather conditions. They can provide expert guidance and ensure that the membrane is applied correctly to achieve the desired waterproofing results. Overall, while it is possible to apply a waterproofing membrane in cold weather or during winter months, it is crucial to choose the right product, prepare the surface properly, and follow the manufacturer's instructions and guidelines to ensure a successful and effective application.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Certainly! Waterproofing membranes can be applied to tunnels that have emergency exits. It is strongly advised to utilize a waterproofing membrane in these tunnels to prevent water infiltration and safeguard the integrity of the exits. These membranes are specifically designed to establish a barrier against water and moisture, guaranteeing that the tunnels stay dry and unharmed by water. This is particularly crucial for emergency exits, as they must remain accessible and operational under all circumstances. By installing a waterproofing membrane, the tunnels can be adequately shielded from potential water ingress, thus ensuring the safety and functionality of the emergency exits.

Send your message to us

SBS Membrane Smooth and Non- Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords