APP Membrane Self-Adhesive Sticky for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

APP MembraneSelf-Adhesive Sticky for Waterproof System

Description Of APP Membrane Self-Adhesive Sticky:

1. APP membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. APP membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. APP membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of APP Membrane Self-Adhesive Sticky:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of APP Membrane Self-Adhesive Sticky:

Material | APP modified asphalt impregnated and coated tire base |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Self-Adhesive Sticky |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of APP Membrane Self-Adhesive Sticky:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

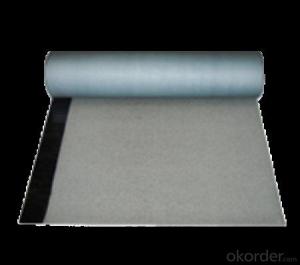

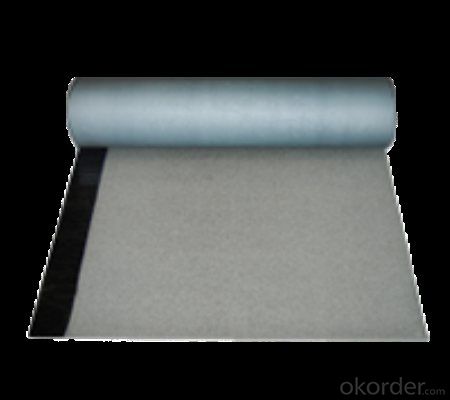

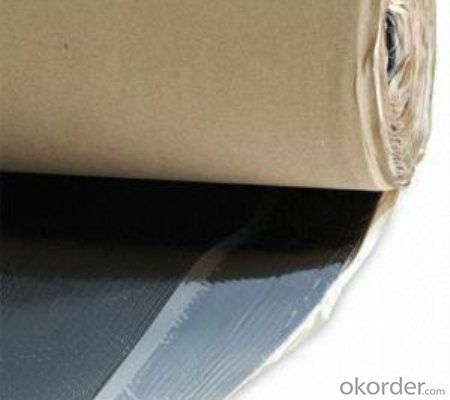

IMages of SBS Self-Adhesive Sticky Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can a waterproofing membrane be used in conjunction with concrete repair or restoration?

- Indeed, it is common practice to utilize a waterproofing membrane in conjunction with concrete repair or restoration. It is advisable to employ a waterproofing membrane as a safeguarding layer on top of repaired or restored concrete surfaces. This is due to the potential compromise of the original concrete's waterproofing properties during the repair or restoration process. Application of a waterproofing membrane guarantees the continued protection of the repaired or restored concrete against water infiltration, thereby preventing additional harm and deterioration. Moreover, the waterproofing membrane contributes to bolstering the overall strength and lifespan of the concrete structure.

- Q: Can a waterproofing membrane be used for a commercial building?

- Indeed, a commercial building can utilize a waterproofing membrane. Specifically engineered to safeguard structures against water damage, these membranes find wide application in commercial settings, encompassing rooftops, basements, and foundation walls. Serving as a protective barrier, the membrane effectively prevents water infiltration, safeguarding against leaks, moisture accumulation, and the growth of mold. Moreover, waterproofing membranes exhibit durability, enabling them to withstand inclement weather conditions, rendering them suitable for commercial buildings exposed to heavy rainfall or extreme temperatures. Ultimately, the incorporation of a waterproofing membrane within a commercial building proves highly effective in preserving long-term structural integrity and averting costly water-related impairments.

- Q: Can a waterproofing membrane be used for a garden pond?

- Indeed, a garden pond can benefit from the use of a waterproofing membrane. Specifically designed to prevent water seepage, this membrane offers an excellent solution for creating a watertight seal in the pond. By lining the pond with this material, one can effectively prevent water leakage and maintain the desired water level. Moreover, the use of a waterproofing membrane also serves to safeguard the pond liner against potential damage from roots, rocks, or other sharp objects, thereby extending the pond's lifespan. However, it is crucial to ensure that the chosen waterproofing membrane is completely safe for aquatic life and does not contain any harmful chemicals that may contaminate the pond water and adversely affect the plants and fish.

- Q: Can waterproofing membranes be used on utility tunnels?

- Yes, waterproofing membranes can be used on utility tunnels. These membranes are designed to provide a barrier against water and moisture, ensuring the protection of the tunnel and its contents from potential water damage.

- Q: How does a waterproofing membrane handle freeze-thaw cycles?

- A waterproofing membrane is designed to withstand freeze-thaw cycles by having specific properties that enable it to expand and contract without compromising its integrity. Freeze-thaw cycles occur when water penetrates the membrane and freezes during colder temperatures, causing it to expand. As the ice melts during warmer temperatures, the membrane should have the ability to contract back to its original state. To handle freeze-thaw cycles, a waterproofing membrane typically possesses elasticity and flexibility, allowing it to accommodate the expansion and contraction without cracking or breaking. It may also have a low water absorption rate to prevent water from seeping into the membrane. Additionally, the membrane should have excellent adhesion to the substrate to ensure it remains in place during temperature fluctuations. Some waterproofing membranes incorporate special additives or technology to enhance their freeze-thaw resistance. These additives may include polymers or elastomers that improve the membrane's ability to withstand extreme temperature changes. Moreover, some membranes have reinforced layers or fabric inserts that provide additional strength and durability, helping them better handle freeze-thaw cycles. Overall, a well-designed waterproofing membrane should be able to handle freeze-thaw cycles effectively by being elastic, flexible, resistant to water absorption, and strongly adhered to the substrate. This ensures the membrane's longevity and prevents water infiltration, protecting structures from potential damage caused by freeze-thaw cycles.

- Q: Can a waterproofing membrane be used on both horizontal and vertical surfaces of a structure?

- Both horizontal and vertical surfaces of a structure can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a barrier against moisture and are commonly utilized in various applications including roofs, basements, foundations, balconies, and walls. Due to their flexibility, they can easily adapt to different surface orientations, making them suitable for both horizontal and vertical installations. The flexibility of the membrane enables it to be applied and adhere effortlessly to different surfaces, effectively protecting against water infiltration and potential damage caused by moisture. Whether it is used on a roof or a wall, a waterproofing membrane is capable of preserving the integrity and longevity of a structure by preventing water penetration and potential water-related issues.

- Q: Can waterproofing membranes be used on elevator pits?

- Indeed, elevator pits can benefit from the utilization of waterproofing membranes. Given their underground location, elevator pits are susceptible to water infiltration, which can lead to detrimental water damage and leaks. To combat these moisture-related issues, waterproofing membranes offer a highly effective solution by preventing water penetration and safeguarding elevator pits. Typically composed of rubber, polyurethane, or bitumen, these membranes are specifically designed to create a watertight barrier. Through their application on the walls and floor of the elevator pit, they form a seamless and durable protective layer. As a result, this membrane system ensures the maintenance of a dry pit, consequently preventing water damage to the elevator components and ensuring the safe and reliable operation of the elevator.

- Q: Can a waterproofing membrane be installed under tile or other flooring materials?

- Yes, a waterproofing membrane can be installed under tile or other flooring materials. Waterproofing membranes are commonly used in areas where moisture may be present, such as bathrooms, kitchens, and basements. These membranes act as a barrier, preventing water from seeping through the floor and causing damage to the underlying structure. They are typically applied directly onto the substrate before the tile or flooring material is installed. This ensures that any water or moisture that may penetrate the flooring is redirected and prevented from reaching the subfloor. By installing a waterproofing membrane, you can protect your floors and extend their lifespan while ensuring a dry and moisture-free environment.

- Q: Can a waterproofing membrane be used for planter boxes and green roofs?

- To ensure the longevity and functionality of planter boxes and green roofs, it is highly recommended to use a waterproofing membrane. This membrane acts as a barrier, preventing water from causing damage to the underlying structures. For planter boxes, a waterproofing membrane is crucial in order to prevent water leakage and protect the surrounding structures. Additionally, it aids in retaining moisture within the planter box, ensuring adequate hydration for the plants. Similarly, green roofs require a waterproofing membrane to prevent water from infiltrating the roof structure and causing leaks or structural damage. This membrane acts as a protective layer, facilitating proper drainage and preventing water accumulation on the roof surface. When choosing a waterproofing membrane for planter boxes and green roofs, durability, flexibility, and resistance to root penetration should be taken into consideration. Some membranes are specifically designed for these applications and offer additional features such as root barriers to prevent damage caused by plant roots penetrating the membrane. In conclusion, a waterproofing membrane is an indispensable component for planter boxes and green roofs. It serves to prevent water leakage, retain moisture, and safeguard the underlying structures from potential damage caused by water infiltration.

- Q: Can waterproofing membranes be used in swimming pools?

- Yes, waterproofing membranes can be used in swimming pools. They are commonly used to create a waterproof barrier that prevents water from seeping through the pool walls or floor, ensuring the pool remains watertight.

Send your message to us

APP Membrane Self-Adhesive Sticky for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords