SBS Membrane fireproof for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SBS Membrane fireproof for Waterproof System

Description Of SBS Membrane fireproof for Waterproof System:

1. SBS membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. SBS membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. SBS membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of SBS Membrane fireproof for Waterproof System:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of SBS Membrane fireproof for Waterproof System:

Material | Ternary Ethylene-Propylene rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Self-Adhesive Sticky |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of SBS Membrane fireproof for Waterproof System:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

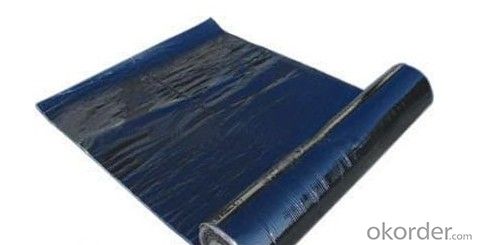

IMages of SBS Membrane fireproof for Waterproof System:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can a waterproofing membrane be used on cinder block surfaces?

- Yes, a waterproofing membrane can be used on cinder block surfaces. Cinder blocks are porous materials that can absorb water, so applying a waterproofing membrane can help prevent moisture from penetrating the surface and causing damage. The membrane acts as a barrier, preventing water from infiltrating the cinder blocks and protecting them from moisture-related issues such as mold, mildew, and deterioration. It is important to properly prepare the cinder block surface before applying the membrane to ensure proper adhesion and effectiveness. Additionally, choosing a waterproofing membrane specifically designed for cinder block surfaces will provide the best results.

- Q: What are the advantages of using a waterproofing membrane?

- One of the main advantages of using a waterproofing membrane is that it provides a reliable and long-lasting solution for preventing water damage. The membrane acts as a barrier, preventing water from seeping into structures and causing issues such as leaks, mold, and deterioration. Additionally, waterproofing membranes are flexible and can be applied to a variety of surfaces, making them a versatile solution for protecting different areas like roofs, basements, and bathrooms.

- Q: How does a waterproofing membrane withstand temperature changes?

- A waterproofing membrane is designed to withstand temperature changes by being made from materials that can expand and contract without losing their properties. These materials are typically flexible and have a high tolerance for temperature fluctuations, allowing them to maintain their waterproofing capabilities even in extreme weather conditions. Additionally, the membrane's installation process often involves proper sealing and adhesion techniques, ensuring that it remains intact and unaffected by temperature changes.

- Q: Can a waterproofing membrane be used in historical or heritage buildings?

- Yes, a waterproofing membrane can be used in historical or heritage buildings. However, it should be done with caution and expertise to ensure that the membrane does not compromise the historical integrity or aesthetic value of the building. The selection and installation of the membrane should be carried out by professionals who understand the specific requirements and challenges associated with preserving the architectural significance of such buildings.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- Yes, a waterproofing membrane can be used in both interior and exterior applications. In interior applications, such as basements or bathrooms, a waterproofing membrane can be installed on walls or floors to prevent water or moisture from seeping through. This helps to protect the underlying structure from damage caused by water intrusion. In exterior applications, a waterproofing membrane can be applied to the exterior walls or foundations of a building to prevent water from penetrating into the structure. This is especially important in regions with heavy rainfall or high water tables. By creating a barrier against water, the membrane helps to keep the interior of the building dry and free from water damage. Overall, the use of a waterproofing membrane in both interior and exterior applications is essential for ensuring the longevity and durability of a structure by protecting it from water-related issues.

- Q: Can a waterproofing membrane be used in conjunction with soundproofing materials?

- Using waterproofing membranes in conjunction with soundproofing materials is a common practice in construction projects. Waterproofing membranes are typically employed to prevent water from entering a structure, while soundproofing materials are used to minimize noise transmission. Although these materials serve different purposes, they can be utilized simultaneously to achieve both waterproofing and soundproofing advantages. For instance, in buildings with basements or bathrooms, waterproofing membranes can be installed on the walls or floors to prevent water infiltration. Subsequently, soundproofing materials can be added on top of the membranes to reduce noise transmission from adjacent areas. By combining these two materials, a building can be safeguarded against water damage while also providing a quieter and more comfortable environment for its occupants.

- Q: Can waterproofing membranes be used on concrete slabs?

- Yes, waterproofing membranes can be used on concrete slabs. These membranes are designed to provide a protective barrier against water infiltration and can effectively prevent moisture from seeping into the concrete.

- Q: Can a waterproofing membrane be used for a retaining wall drainage?

- Using a waterproofing membrane is an effective method for retaining wall drainage. Typically used to prevent water from penetrating structures like basements or foundations, this membrane can also serve as a barrier against water seepage in retaining wall construction. Retaining walls are designed to hold back soil and prevent erosion, but without proper construction, they can be vulnerable to water damage. If water seeps through, it can create pressure behind the wall, causing structural problems over time. By installing a waterproofing membrane on the backside of the retaining wall, water infiltration into the soil and accumulation behind the wall can be prevented. Furthermore, a waterproofing membrane can help with the drainage of water away from the retaining wall. By incorporating drainage systems like weep holes or French drains, alongside the membrane, water can be directed away from the wall, reducing hydrostatic pressure and potential damage. It's important to note that while a waterproofing membrane can be used for retaining wall drainage, proper installation and compatibility with the specific retaining wall system and conditions are crucial. It's recommended to consult with a professional engineer or contractor experienced in retaining wall construction to ensure the most suitable approach for your specific project.

- Q: Does a waterproofing membrane require a protective layer?

- Yes, a waterproofing membrane typically requires a protective layer. The protective layer helps to shield the membrane from various external factors, such as UV rays, weather conditions, mechanical damage, and chemical exposure, thereby enhancing its durability and longevity.

- Q: Can a waterproofing membrane be used for loading docks?

- Yes, a waterproofing membrane can be used for loading docks. Waterproofing membranes are commonly used in construction and can provide a protective barrier against water intrusion, which can be beneficial for loading docks that may be exposed to rain, snow, or other forms of moisture. By applying a waterproofing membrane to the surface of the loading dock, it can help prevent water damage, deterioration, and potential safety hazards.

Send your message to us

SBS Membrane fireproof for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords