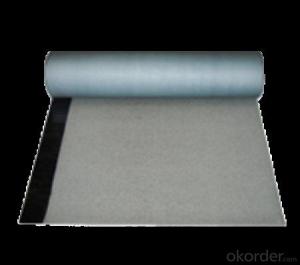

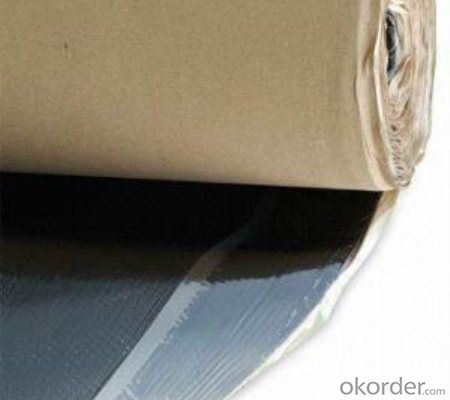

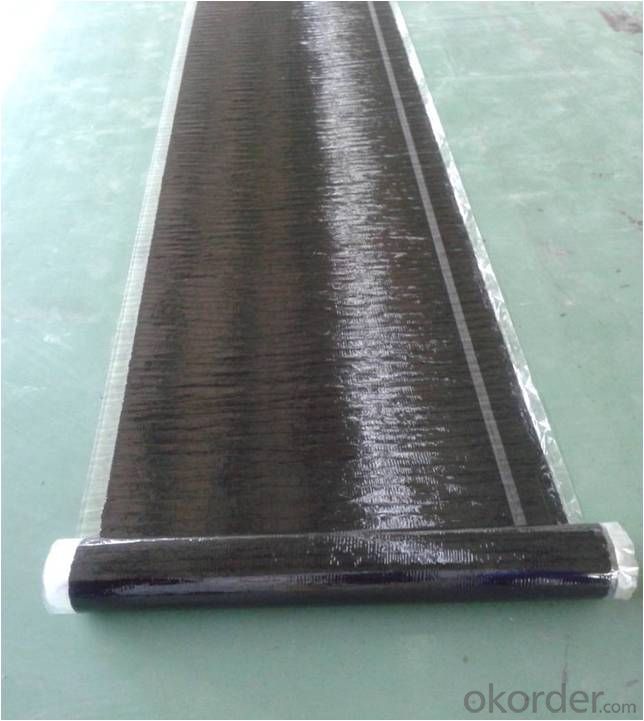

SBS Membrane Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SBS Membrane Smooth for Waterproof System

Description Of SBS Membrane Smooth for Waterproof System:

1. TPO Membrane Smooth is made from Thermoplastic polyethylene hydrocarbons , which is for waterproofing of exposed and non-exposed applications.

2. TPO Membrane Smooth adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. TPO Membrane Smooth is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of SBS Membrane Smooth for Waterproof System:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of SBS Membrane Smooth for Waterproof System:

Material | SBS modified asphalt impregnated and coated tire base |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m |

Thick | 1.2mm, 1.5mm, |

Type | Smooth |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of SBS Membrane Smooth for Waterproof System:

1.Roofs, Basement

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

IMages of TPO Membrane Smooth for Waterproof System:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can a waterproofing membrane be used for historic preservation projects?

- Yes, a waterproofing membrane can be used for historic preservation projects. Waterproofing membranes are commonly used in construction to protect buildings from water damage, and they can be particularly beneficial in preserving historic structures. By preventing water infiltration, the membrane helps to safeguard the integrity of the building, protect against moisture-related deterioration, and extend the lifespan of the historic structure. However, it is important to ensure that the membrane chosen is compatible with the materials and construction techniques used in the historic building to avoid any adverse effects on its authenticity or structural stability.

- Q: Can a waterproofing membrane be used in swimming pools or other water features?

- Yes, a waterproofing membrane can definitely be used in swimming pools or other water features. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water leakage and damage. A waterproofing membrane acts as a barrier between the water and the surrounding structures, ensuring that the water is contained within the pool or water feature. It helps to prevent water seepage, which can cause structural damage and lead to costly repairs. Additionally, a waterproofing membrane also helps to protect the pool or water feature from the harsh chemicals used for water treatment, ensuring its longevity and durability. Therefore, using a waterproofing membrane is a crucial step in the construction or renovation of swimming pools or other water features to ensure their functionality and longevity.

- Q: Can a waterproofing membrane be used on PVC roofs?

- PVC roofs, commonly found in commercial and residential buildings, are known for their durability and resistance to weathering. However, like all roofing materials, they can develop leaks and cracks over time. To combat this issue, a waterproofing membrane can be applied to PVC roofs. This membrane, such as EPDM or TPO, is flexible and can easily adhere to the PVC surface, forming a seamless and watertight barrier. It is crucial to ensure that the chosen waterproofing membrane is compatible with PVC roofs and to carefully follow the manufacturer's instructions for proper installation. Additionally, regular maintenance and inspections are highly recommended to promptly detect and address any potential problems before they worsen.

- Q: Can a waterproofing membrane be used on aerated concrete block surfaces?

- Yes, a waterproofing membrane can be used on aerated concrete block surfaces. The membrane helps to prevent water penetration, protecting the aerated concrete blocks from moisture damage and increasing their longevity.

- Q: Can a waterproofing membrane be used in renovation or retrofitting projects?

- Certainly, a waterproofing membrane is a viable option for use in renovation or retrofitting endeavors. In fact, it often plays a crucial role in these projects, guaranteeing the long-term resilience and safeguarding of the building or structure. Waterproofing membranes are specifically designed to establish a barrier against moisture infiltration, effectively thwarting water damage, mold proliferation, and structural decay. When engaging in renovation or retrofitting tasks, it is not uncommon to encounter predicaments such as leaks, cracks, or deteriorated building materials that undermine the building's waterproofing system. In such scenarios, the application of a waterproofing membrane over the affected areas proves to be a reliable method of sealing and protecting them from further harm. This can be accomplished both internally and externally, tailored to the specific requirements at hand. Waterproofing membranes are available in a variety of forms, including sheet membranes, liquid coatings, or spray-applied membranes. They can be employed on various surfaces such as roofs, walls, basements, and even foundations. These membranes possess qualities such as flexibility, durability, and resistance to water and other environmental pressures, rendering them exceptional for renovation or retrofitting undertakings where augmenting the building's waterproofing capabilities is imperative. In conclusion, it is highly advisable to incorporate a waterproofing membrane into renovation or retrofitting ventures to ensure the endurance and integrity of the building. It serves as a proactive measure to preclude future water damage, preserve structural stability, and enhance the overall quality of the revitalized or retrofitted space.

- Q: Can a waterproofing membrane be used on plywood surfaces?

- Plywood surfaces can benefit from the use of a waterproofing membrane. Plywood is commonly used in construction, including outdoor projects like decks and balconies. However, plywood is not naturally waterproof and can suffer from moisture damage over time. To safeguard plywood surfaces from water damage, a waterproofing membrane can be employed. This membrane functions as a barrier, preventing water from penetrating the plywood and causing rot or decay. There exist various types of waterproofing membranes, such as liquid-applied membranes, sheet membranes, and peel-and-stick membranes. These membranes adhere to the plywood surface and create a tight seal. It is crucial to adhere to the manufacturer's instructions for proper application and ensure the plywood surface is clean and dry before applying the membrane. By utilizing a waterproofing membrane, plywood surfaces can be effectively shielded from water damage, prolonging their lifespan and preserving their structural integrity.

- Q: Can a waterproofing membrane be used for schools or universities?

- Yes, a waterproofing membrane can definitely be used for schools or universities. These membranes are designed to provide protection against water damage, preventing leaks and moisture intrusion in buildings. By installing a waterproofing membrane, schools and universities can ensure the longevity of their structures, protect valuable assets, and maintain a safe and comfortable environment for students and faculty.

- Q: Can waterproofing membranes be applied in cold weather?

- Yes, waterproofing membranes can be applied in cold weather. However, it is important to consider a few factors when applying these membranes in low temperatures. Cold weather can affect the curing process of the membrane, potentially slowing it down. It is crucial to ensure that the surface being waterproofed is dry and free from ice or frost before applying the membrane. Additionally, some waterproofing products may have specific temperature requirements for optimal performance, so it is essential to consult the manufacturer's guidelines. In colder temperatures, it may also be necessary to use specialized adhesives or primers designed for cold weather applications. Overall, with proper precautions and the use of appropriate materials, waterproofing membranes can be successfully applied in cold weather.

- Q: Can waterproofing membranes be used in cold climates?

- Yes, waterproofing membranes can be used in cold climates. They are designed to withstand extreme temperatures, including freezing conditions, and provide effective protection against water penetration.

- Q: Can a waterproofing membrane be used for soundproofing purposes?

- Yes, a waterproofing membrane can be used for soundproofing purposes to some extent. While its primary function is to prevent water penetration, it can also help to reduce sound transmission. Waterproofing membranes are typically made of materials that have good acoustic properties, such as rubber or a combination of rubber and asphalt. These materials can absorb and dampen sound waves, thereby reducing the amount of noise that passes through a wall or floor. However, it is important to note that the soundproofing effectiveness of a waterproofing membrane may not be as high as that of specialized soundproofing materials like acoustic panels or insulation. Therefore, if soundproofing is the main goal, it is recommended to consider using dedicated soundproofing solutions in addition to or instead of a waterproofing membrane.

Send your message to us

SBS Membrane Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords