SBS / APP Modified Bitumen Sheet Waterproofing Membrane for Ponds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of SBS / APP Modified Bitumen Sheet Waterproofing Membrane:

1. Asphalt roofing shingles are lightweight, glass fibre based bitumen strip slates. They are easily installed and the appearance of a highly decorative tiled roof finish. Asphalt shingles are exported to Britain, Asia, South America, Africa and so on.

Main Features of SBS / APP Modified Bitumen Sheet Waterproofing Membrane:

1) Size: 1000*333mm

2) Thick: 2.7mm, 5.2mm

3) Types: 3-Tab, Laminated, Mosaic, Fish-scale, Goethe

4) 12 colors

5) Weight: 9.5-12.5kgs/m2

6) Packing: 21pcs or 16pcs/bundle, 800-1000bundles/20' GP, wood pallet

7) Accessories: bitumen mastic, nails, roof underlayment

8) Warranty Time: 20-30 years

9) Temperature: -45°C to 130°C

10) Certificates: ISO14001:2004, ISO9001:2008

Specifications of SBS / APP Modified Bitumen Sheet Waterproofing Membrane:

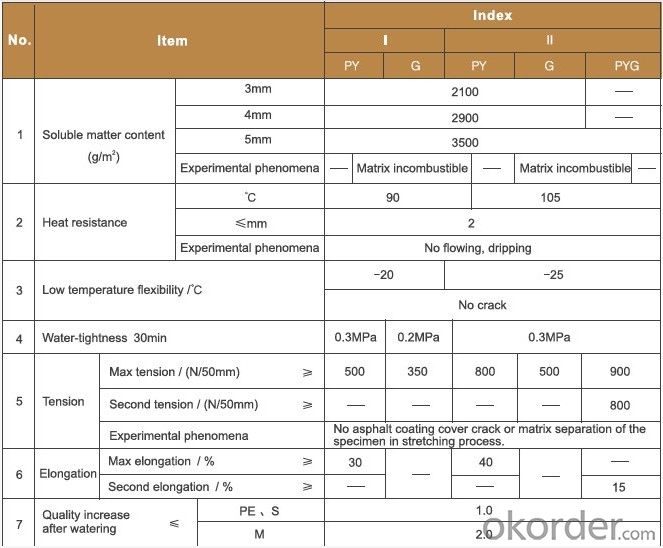

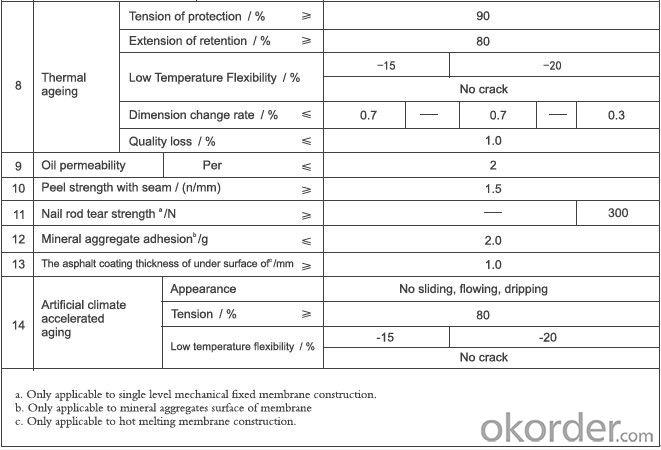

Physical Performance: Executive GB18242-2008

Storage and Transportio

Applications of EPDM Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

IMages of SBS / APP Modified Bitumen Sheet Waterproofing Membrane:

FAQ:

Q1.:What are we supplying?

A1:We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

Q2: How Many years experience do we have?

A2:We have exported to more than 20 countries in the past 15 years.

Q3.:Do you provide samples for us?

A3:Yes,We will provide samples for free.Waiting for your your good news.

- Q: Can a waterproofing membrane be used for a bridge deck construction?

- Bridge deck construction can utilize a waterproofing membrane. This membrane is a thin material layer applied to the bridge deck to prevent water infiltration and safeguard the underlying structure against corrosion and deterioration. To ensure the bridge's longevity and durability, it is commonly employed in bridge deck construction. The waterproofing membrane functions as a moisture barrier, effectively stopping water and other liquids from penetrating the surface of the bridge deck. This is especially vital for bridge decks as they are constantly exposed to various weather conditions, including rain, snow, and ice, which can cause gradual harm. Apart from its water resistance properties, the waterproofing membrane also provides protection against other elements like UV rays and chemicals that can deteriorate the bridge deck surface. By obstructing water and other detrimental substances from reaching the bridge deck, the membrane aids in extending the bridge's lifespan while reducing maintenance and repair expenses. Moreover, the waterproofing membrane contributes to the overall safety of the bridge by minimizing the risk of structural damage caused by water infiltration. By keeping the bridge deck dry, it helps preserve the bridge's integrity and prevents potential hazards such as slippery surfaces or weakened structural components. In conclusion, the waterproofing membrane is an essential element in bridge deck construction as it guarantees the long-term functionality and durability of the bridge. Its ability to protect against water infiltration, UV rays, and chemicals makes it an ideal choice for enhancing the performance and lifespan of a bridge.

- Q: Can a waterproofing membrane be used for underground utility vaults?

- Yes, a waterproofing membrane can be used for underground utility vaults. Waterproofing membranes are commonly used to prevent water infiltration and protect structures from moisture damage. In the case of underground utility vaults, where there is a high risk of groundwater seepage, a waterproofing membrane can provide an effective barrier against water penetration, ensuring the vault remains dry and protected from potential water-related issues.

- Q: Can a waterproofing membrane be used on balconies and decks?

- Balconies and decks can benefit greatly from the use of a waterproofing membrane. It is highly recommended to install this protective layer to safeguard against water damage. These outdoor areas are exposed to rain, snow, and other weather conditions, which can lead to issues like rot, mold, and structural deterioration if water seeps into the structure. By applying a waterproofing membrane beneath the surface material, such as tiles or decking, a barrier is created that prevents water from penetrating and redirects it away from the structure. This not only prolongs the life of the balcony or deck but also preserves its visual appeal. Moreover, the use of a waterproofing membrane is particularly crucial for balconies located above living spaces, as it prevents water from dripping down. In conclusion, incorporating a waterproofing membrane is an effective solution to ensure the durability and functionality of balconies and decks.

- Q: Are there any specific considerations for installing a waterproofing membrane on metal surfaces?

- Installing a waterproofing membrane on metal surfaces requires specific considerations. It is crucial to choose a membrane that is compatible with the type of metal being used, as some membranes may not adhere well to certain metals. Proper preparation of the metal surface is also important, which may involve thorough cleaning to remove dirt and contaminants, as well as priming to improve adhesion. Another factor to consider is the expansion and contraction of the metal surface due to temperature changes. This movement can potentially affect the performance of the waterproofing membrane, so it is necessary to select a membrane that can accommodate the metal's movement without compromising its waterproofing capabilities. The type of waterproofing membrane being used is also significant. Liquid-applied membranes, sheet membranes, and peel-and-stick membranes each have their own installation requirements, and it is important to follow the manufacturer's guidelines for proper installation on metal surfaces. Additionally, other factors such as exposure to UV radiation, potential for corrosion, and compatibility with other building materials or systems should be taken into account. Considering these factors will help ensure a successful and long-lasting installation of a waterproofing membrane on metal surfaces.

- Q: Does a waterproofing membrane require any specific safety precautions during installation?

- Yes, installing a waterproofing membrane does require specific safety precautions. These may include wearing protective clothing, such as gloves and goggles, to prevent contact with chemicals or materials that may be harmful. It is important to ensure proper ventilation in the installation area to minimize exposure to potentially harmful fumes or vapors. Additionally, following manufacturer's instructions, using proper tools and equipment, and working in a well-organized manner can help prevent accidents or injuries during the installation process.

- Q: Can a waterproofing membrane be removed or replaced if necessary?

- If necessary, one can remove or replace a waterproofing membrane. Over time, these membranes may deteriorate or sustain damage, resulting in leaks or moisture seepage. In such instances, it becomes necessary to remove the current membrane and install a new one to ensure effective waterproofing. This removal and replacement process entails meticulously peeling away the old membrane, cleansing the surface, and applying a fresh membrane system. Consulting a skilled waterproofing contractor is crucial as they can evaluate the condition of the existing membrane and offer suitable guidance for its removal and replacement.

- Q: Can a waterproofing membrane be used for a shower pan liner installation?

- Yes, a waterproofing membrane can be used for a shower pan liner installation. A waterproofing membrane is designed to create a barrier against moisture and prevent water from seeping through the shower pan and causing damage to the underlying structure. It is essential to have a reliable and effective waterproofing system in place to ensure the longevity and integrity of the shower installation. A waterproofing membrane can provide this protection by effectively sealing the shower pan and creating a watertight barrier. It is important to choose a membrane specifically designed for use as a shower pan liner and to follow the manufacturer's instructions for proper installation.

- Q: Does a waterproofing membrane require any specific cleaning methods?

- Yes, a waterproofing membrane typically requires specific cleaning methods. It is important to avoid using abrasive cleaners or tools that may damage the membrane. Instead, gentle cleaning solutions and soft brushes or cloths should be used to remove dirt and debris without compromising the membrane's integrity. Regular maintenance and cleaning will help prolong the lifespan and effectiveness of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for elevator pits and sump pits?

- Yes, a waterproofing membrane can be used for elevator pits and sump pits. Elevator pits and sump pits are generally prone to water leakage and moisture issues, which can cause damage to the structural integrity of the pits and surrounding areas. To prevent such issues, waterproofing membranes are commonly used to create a barrier against water intrusion. A waterproofing membrane is designed to be highly resistant to water penetration and can effectively seal the elevator and sump pits, preventing water from seeping in. These membranes are typically made of materials such as rubberized asphalt, ethylene propylene diene terpolymer (EPDM), or polyvinyl chloride (PVC) and are applied to the walls and floors of the pits. By installing a waterproofing membrane, the elevator and sump pits can be protected from water damage, including potential corrosion, mold growth, and structural deterioration. This not only helps to maintain the functionality and longevity of the pits but also ensures a safe and healthy environment for occupants and equipment. However, it is important to consider the specific requirements and regulations of elevator and sump pit installations, as different jurisdictions may have specific codes and standards that need to be followed. Additionally, proper installation and regular maintenance of the waterproofing membrane are crucial to ensure its effectiveness in preventing water infiltration.

- Q: Can a waterproofing membrane be used on aluminum surfaces?

- Yes, a waterproofing membrane can be used on aluminum surfaces.

Send your message to us

SBS / APP Modified Bitumen Sheet Waterproofing Membrane for Ponds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords