APP/SBS Modified Bitumen Waterproof Membrane For Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CE approved waterproof membrane price , self adhesive textured roll sbs waterproof membrane

product description:

CE approved waterproof membrane price , self adhesive textured roll sbs waterproof membrane take the “Skin” type waterproof thought, according to the features of construction site, on the basis of width elastomeric modified bitumen waterproofing membrane, combining with features of wet-application self-adhesive membrane, use advanced equipment to produce 2 meters width that WP-SBS wet-application width elastomeric modified bitumen waterproofing membrane (Hereinafter referred to: WP-SBS membrane).WP-SBS is made of bitumen modified with Styrene-Butadiene- Styrene (SBS)as dipping and painting. Its upper surface covers PE membrane and color sand or schist, and lower surface is made of isolation material. Products correspond to the national standards GB18242-2008(elastomeric modified bitumen waterproofing membrane), paste by cement or cement mortar, and construct on the wet base, achieving tight and full adhesion with substrates, eliminating fluid-channeling layer, all above contribute to making a reliable “Skin” type waterproof system, which is a breakthrough innovation in ordinary modified bitumen membrane.

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Characteristic

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable scope:

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application method:

1.Make sure the roof deck smooth ,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2.There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3.After application ,a full serious inspection is required to make sure no air bubble ,no fold,no falling away etc to guarantee the waterproof life.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Product usage of pe compound waterproof membrane

The products are widely used in projects of compound geomembrane impervious

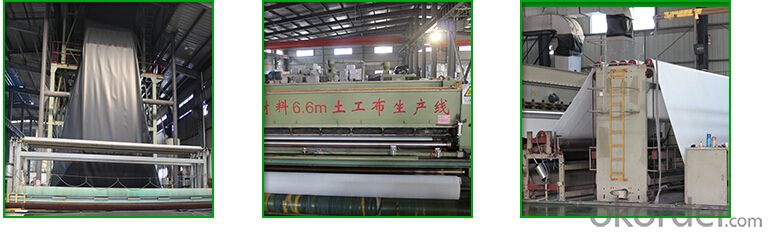

Product line&test

♦Product line

From raw materials to finished products, every process is tested and controlled professionally and seriously by our professional machines and person.

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Why choose us ?

We have 20 years manufacturer experience

10000-30000 square meter factory size,more than 10 production lines

We will be your best partner,provide high quality products with CE,ISO,SGS

approved in competitive prive,sincerely hope to make a win-win cooperation with you.

FAQ

- Q: Can a waterproofing membrane be used in conjunction with a drainage system?

- Yes, a waterproofing membrane can be used in conjunction with a drainage system. In fact, it is often recommended to use both together for effective waterproofing and drainage in areas such as basements, roofs, and foundations. The waterproofing membrane acts as a barrier to prevent water from seeping through the surface, while the drainage system helps to remove any excess water that may accumulate. By combining these two systems, it ensures a comprehensive solution to protect the structure from potential water damage.

- Q: Can a waterproofing membrane be used on stone block surfaces?

- Yes, a waterproofing membrane can be used on stone block surfaces. The membrane creates a protective barrier that prevents water penetration and helps to maintain the integrity of the stone blocks. However, it is essential to ensure that the appropriate type of waterproofing membrane is selected and installed correctly to ensure proper adhesion and durability on the stone surface.

- Q: Can a waterproofing membrane be painted over?

- Indeed, painting over a waterproofing membrane is possible. Nevertheless, it is crucial to guarantee the cleanliness, dryness, and absence of any debris or loose substances on the membrane prior to applying paint. Furthermore, it is advised to employ a paint specifically formulated for waterproofing membranes in order to achieve proper adhesion and durability. It is equally essential to adhere to the manufacturer's guidelines for both the waterproofing membrane and the paint to ensure compatibility and effectiveness.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Certainly! Below is a rewritten version of the passage: Indeed, elevator pits or sump pits can benefit from the utilization of a waterproofing membrane. These pits are prone to water infiltration, but the application of a waterproofing membrane can effectively prevent water seepage. By acting as a barrier, the membrane stops any water from entering the pit and causing harm to the elevator or pumping system. Consequently, this safeguards the longevity and integrity of the elevator or pump. Moreover, the waterproofing membrane also safeguards the surrounding structures from water damage. Thus, it is crucial to select a suitable waterproofing membrane that is specifically designed for below-ground applications and possesses the necessary properties to withstand the unique conditions within an elevator or sump pit.

- Q: Can a waterproofing membrane be used in conjunction with energy-efficient building designs?

- Yes, a waterproofing membrane can be used in conjunction with energy-efficient building designs. In fact, incorporating a waterproofing membrane into the construction of an energy-efficient building can provide several benefits. Firstly, a waterproofing membrane helps to protect the building envelope from water infiltration, which is critical for maintaining the integrity and longevity of the structure. By preventing water damage, the building can avoid costly repairs and potential energy losses caused by moisture intrusion. Additionally, a well-designed waterproofing system can contribute to the energy efficiency of the building by reducing the need for mechanical heating and cooling. By preventing moisture from entering the building envelope, the waterproofing membrane helps to maintain a consistent indoor temperature, reducing the load on HVAC systems and improving energy efficiency. Furthermore, certain types of waterproofing membranes, such as those with reflective or heat-resistant properties, can also contribute to energy savings by reducing heat transfer through the building envelope. These membranes reflect solar radiation, reducing the amount of heat absorbed by the building, and thus decreasing the demand for cooling. Lastly, waterproofing membranes can be integrated with other energy-efficient building components, such as green roofs or rainwater harvesting systems. These systems can help to further reduce energy consumption by providing insulation, reducing stormwater runoff, and promoting sustainable water management practices. Overall, incorporating a waterproofing membrane into an energy-efficient building design can enhance both the durability and energy performance of the structure. It offers protection against water damage, reduces the load on mechanical systems, and can be integrated with other sustainable features, making it a valuable component of energy-efficient building designs.

- Q: What are the different types of waterproofing membranes?

- Construction and building projects commonly utilize various types of waterproofing membranes to prevent water penetration through walls, roofs, or other structures. These membranes can be applied to different surfaces. 1. Bituminous Membranes: Comprised of bitumen, polymers, and reinforcement materials like fiberglass or polyester, bituminous waterproofing membranes are frequently employed in roofing applications. They can be applied using hot or cold processes and offer outstanding waterproofing properties and durability. 2. PVC Membranes: Synthetic PVC membranes exhibit high resistance to water, chemicals, and UV radiation. They are often used in roofing applications, particularly for flat or low-slope roofs. PVC membranes are lightweight, flexible, and easy to install, boasting long-lasting waterproofing protection while being puncture and tear-resistant. 3. EPDM Membranes: Synthetic rubber EPDM membranes find common use in roofing applications. These membranes are highly durable, flexible, and resistant to UV radiation, ozone, and extreme temperatures. They can be installed as a single-ply membrane or in combination with other materials. 4. TPO Membranes: TPO membranes, a type of single-ply roofing membrane, are commonly employed in commercial and industrial settings. Composed of polymer blends and reinforcement materials, TPO membranes exhibit high resistance to water, chemicals, and UV radiation. They are lightweight, flexible, and easy to install. 5. Liquid Applied Membranes: Liquid applied membranes are an application type where the waterproofing system is initially liquid and cures to form a seamless and flexible membrane. These membranes can be made from various materials such as acrylic, polyurethane, or rubber-based compounds. They are often used for below-grade applications like basements or foundations, as well as roofs or other surfaces. To ensure effective and long-lasting waterproofing protection, it is crucial to consider the specific project requirements and consult with professionals to determine the most suitable type of waterproofing membrane.

- Q: Does a waterproofing membrane require any special maintenance?

- Yes, a waterproofing membrane does require some special maintenance. While it is designed to be durable and withstand various weather conditions, regular maintenance is necessary to ensure its effectiveness and longevity. Some maintenance tasks include: 1. Regular inspections: Check the membrane for any signs of damage, such as cracks, tears, or punctures. Inspect the seams and edges to ensure they are properly sealed. 2. Clean the surface: Remove any debris, dirt, or vegetation that may have accumulated on the membrane. This can be done using a broom, brush, or pressure washer (if recommended by the manufacturer). 3. Clear drains and gutters: Ensure that the drains and gutters connected to the membrane are not clogged or blocked. This will prevent water from pooling on the surface and potentially causing damage. 4. Repair any damages: If any cracks, tears, or punctures are found, they should be repaired promptly to prevent water leakage. Follow the manufacturer's instructions for the appropriate repair method and materials. 5. Regularly check the waterproofing system: If the membrane is part of a larger waterproofing system, such as a basement or roof, it is important to inspect and maintain the entire system. This may involve checking the integrity of other components, such as drainage pipes or flashing. 6. Consider professional maintenance: Depending on the size and complexity of the waterproofing system, it may be beneficial to hire a professional maintenance service. They can conduct thorough inspections, perform necessary repairs, and provide expert advice on maintaining the membrane. By following these maintenance practices, you can ensure that your waterproofing membrane remains in good condition and effectively protects your structure from water damage.

- Q: Modified asphalt waterproofing membrane SBS I G PE4 What does it mean?

- SBS is called the elastomer modified asphalt waterproofing membrane, I on behalf of the model, GK is the tire base for the polyester tire base, PE four on behalf of the membrane for the double-sided PE film four mm thick.

- Q: Can a waterproofing membrane be used for bridge or tunnel waterproofing?

- Yes, a waterproofing membrane can be used for bridge or tunnel waterproofing. Waterproofing membranes are commonly used in construction projects to prevent water penetration and protect structures from potential damage caused by moisture. In the case of bridges and tunnels, which are exposed to harsh environmental conditions and high water pressure, a high-quality waterproofing membrane can effectively provide an impermeable barrier, ensuring the long-term durability and structural integrity of these infrastructure elements.

- Q: What is the difference between pressure-sensitive self-adhesive waterproofing membrane and sbs asphalt waterproofing membrane?

- 2, from the construction method (1) pressure-sensitive self-adhesive waterproof membrane is the use of wet shop method, that is, the base surface and the membrane should engage in cement slurry, and finally, the shop on it. And sbs asphalt waterproofing membrane using the roasted method, quite troublesome. So from the construction method, the two differences are relatively large, the former construction more convenient.

Send your message to us

APP/SBS Modified Bitumen Waterproof Membrane For Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords