Sandwichpanel Prefabricated House | Camp House Sandwichpanele

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Eps Sandwich Panel Water Proof Sandwich Panel

Light weight

High intensity Sound proof Easy installation

Eps Sandwich Panel Water Proof Sandwich Panel

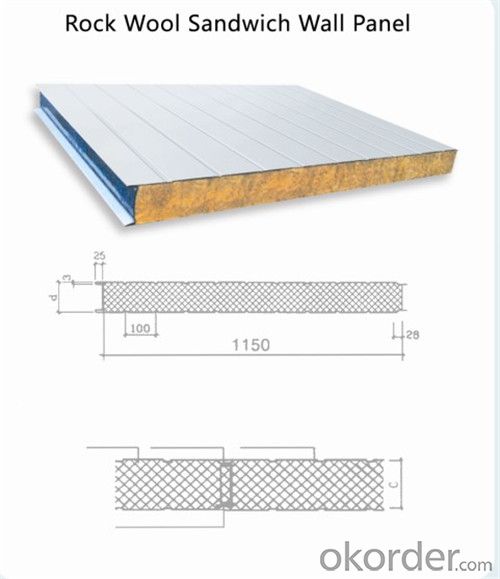

The usual sandwich panels include rock wool Sandwich panel, EPS sandwich panels, PU Sandwich Panel, glass fiber sandwich pannels. The up & down surface of this panel is Galvanized & Prepainted steel sheets, core material is rock rood, EPS, PU, and glass fiber. It is formed by heating, foaming & laminating. It is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Specifications

(1)Core Material: Rock Wool, EPS, PU; Surface Materials: Galvanized Steel sheets or Prepainted Steel sheets.

(2)Wall Thickness: 40, 50, 60, 80,100,120,150,180,200,250mm

(3)Max. Width: 1200mm

(4)Length: according to client's demands, engineering requirements and shipment conditions

(5) Application: for ceiling & wall, partition wall

(6) Widely used in common steel structure and storey adding projects,e.g. adding storey to small steel structure industrid factory building worehouse,suburbon temporary office,residentid quarters,school,hospital,etc.

Characteristics

1) With a light weight, a giraffe fitting and random incise characteristic, the fitting is much simpler, and it can advance the benefit and save the time limit for a project

2) Color coated sandwich panel's surface material and heat preservation material are non-burn or hard-burn materials, entirely satisfy the fireproofing criterion request

3) Manifold disquisition and oversea used approving more than 40 years. By especial coated dispose, the color coated steel panel's guaranty is 10-15 years, and the panel's life express 35 years by painting the antisepsis material after each 10 years

4) Pressing steel panel with the clear line, and many colors for choice, and suit with any different building style materials, achieving the satisfying effects.

5) In common use heat preservation materials are rock-wool, polystyrene,

polyurethane, all with lower thermal conductivity and favorable heat preservation and heat insulation effects

6) Sound insulation intension can be 40-50dB, it is the most effective sound insulation material

7) Pressing steel panel can be arbitrariness incise, it can satisty the especially design demands

8) Use the high strength steel panel for the base metal (contradict open and pull intension 5,600kg/cm2), adding the most advanced design and roll pressing moulding, it gets the best structure character

9) Improves speediness and springiness designs according to clients' requirements.

- Q: What are the considerations for the design of steel structures in areas prone to landslides?

- In areas prone to landslides, it is crucial to take several important considerations into account when designing steel structures. These considerations play a pivotal role in ensuring the safety and stability of the structures in hazardous environments. Key factors to consider include the following: 1. Conducting a thorough site investigation is essential to gain a comprehensive understanding of the geological conditions, such as soil composition, stability, and potential landslide risks. This investigation helps evaluate the severity of the landslide hazards and determine appropriate design measures. 2. The structural design of steel structures in landslide-prone areas should be robust enough to withstand the potential forces generated by landslides. This involves designing for increased loads, such as impact forces and soil pressures, that may be exerted on the structure during a landslide event. 3. Proper foundation design is crucial in areas prone to landslides. The foundation should be designed to resist lateral forces exerted by the sliding mass and provide adequate stability against soil movement. Techniques like soil stabilization, ground treatment, and deep foundations may be necessary to enhance foundation stability. 4. Slope stabilization measures should also be considered when designing steel structures in landslide-prone areas. These measures may include installing retaining walls, geotextiles, soil nails, or other techniques to prevent or mitigate landslides near the structure. 5. An effective drainage system is vital to control groundwater and surface water flow. Excessive water accumulation can increase the likelihood of landslides, so proper drainage design should be implemented to prevent water infiltration and accumulation around the structure. 6. Continuous monitoring and regular maintenance are essential for steel structures in landslide-prone areas to detect any signs of instability or damage. Monitoring systems, such as inclinometers, strain gauges, or settlement markers, can help identify potential landslide movements and trigger appropriate response measures. 7. Developing an emergency response plan is important for steel structures in landslide-prone areas. This plan should outline procedures for evacuation, emergency repairs, and post-landslide assessment to ensure the safety of occupants and minimize potential damage. By considering these factors, engineers and designers can develop steel structures that are better equipped to withstand the challenges posed by landslides. This ensures the safety of occupants and the longevity of the structures in these high-risk areas.

- Q: How are steel structures designed to resist lateral loads?

- Steel structures are designed to resist lateral loads through various methods such as the use of bracing systems, shear walls, moment-resisting frames, and base isolation techniques. These elements are strategically incorporated into the design to provide stability and strength against lateral forces, such as wind or seismic loads. The choice of the specific design method depends on factors like the type of structure, local building codes, and anticipated loads. Overall, steel structures are engineered with careful consideration of lateral load resistance to ensure their safety and stability.

- Q: How are steel structures used in the construction of residential complexes and apartments?

- Steel structures are commonly used in the construction of residential complexes and apartments due to their strength, durability, and versatility. Steel allows for large open spaces, which is especially desirable in residential buildings. It is used for load-bearing columns, beams, and frames, providing stability and allowing for multiple stories. Additionally, steel is resistant to fire, pests, and natural disasters, enhancing the safety and longevity of the structures. Its lightweight nature also allows for efficient transportation and assembly. Overall, steel structures play a crucial role in ensuring the construction of safe, efficient, and modern residential complexes and apartments.

- Q: How are steel structures designed and constructed to meet accessibility codes?

- Various methods and considerations are utilized in the design and construction of steel structures to meet accessibility codes. To begin with, the design phase focuses on incorporating features that make the structure accessible for individuals with disabilities. These features encompass ramps, elevators, and accessible parking spaces. In terms of construction, steel structures adhere to specific guidelines and regulations set by accessibility codes. These codes stipulate requirements for dimensions, clearances, slopes, and handrails, among other factors, in order to guarantee accessibility. In the construction process, particular attention is given to creating pathways and entrances that are sufficiently wide to accommodate wheelchair users comfortably. Additionally, ramps and elevators are constructed with precise dimensions and specifications to cater to individuals with mobility impairments. The installation of handrails is also a crucial aspect. They are positioned at appropriate heights and designed to provide a secure grip for individuals facing mobility challenges. Moreover, tactile warning surfaces are often integrated into the design to assist visually impaired individuals in navigating the structure. Furthermore, steel structures are designed to ensure that all areas, including restrooms, meeting rooms, and common areas, are accessible to individuals with disabilities. This encompasses features such as accessible toilets, sinks, and doorways that meet the required dimensions. In summary, the design and construction of steel structures to meet accessibility codes necessitate meticulous planning and adherence to specific guidelines. This guarantees that individuals with disabilities can safely and independently access and navigate the structure.

- Q: How are steel structures designed to resist snow loads?

- Steel structures are designed to resist snow loads by considering factors such as the weight of the snow, the geographical location, and the building's shape and design. Engineers calculate the maximum expected snow load and design the structure to withstand this load by incorporating appropriate factors of safety. This can include using stronger steel sections, increasing the number and size of supports, and incorporating sloped roofs to allow for snow shedding. Additionally, regular maintenance and monitoring of the structure are essential to ensure its continued resistance to snow loads.

- Q: What are the common design considerations for steel pedestrian bridges?

- Some common design considerations for steel pedestrian bridges include the load capacity requirements, aesthetic appeal, durability and resistance to corrosion, ease of maintenance, integration with the surrounding environment, accessibility for people with disabilities, and adherence to safety standards and codes.

- Q: How are steel structures designed to resist progressive collapse?

- Steel structures are designed to resist progressive collapse through various measures such as redundancy, robustness, and enhanced connection design. Redundancy involves the provision of alternative load paths to ensure that the structure remains stable even if one or more elements fail. Robustness refers to the ability of the structure to withstand localized damage without resulting in a catastrophic collapse. Enhanced connection design focuses on creating stronger and more resilient connections between structural elements to prevent the propagation of failures. These design strategies work together to ensure that steel structures can effectively resist progressive collapse and maintain their stability and integrity.

- Q: What are the common challenges faced during the construction of steel structures?

- During the construction of steel structures, one may encounter several common challenges. These challenges are as follows: 1. Design complexity: The design of steel structures often involves intricate calculations and detailing. Meeting the requirements for structural integrity, load distribution, and architectural functionality can be challenging. 2. Handling and transportation of materials: Steel structures require large quantities of steel components, which can be heavy and difficult to handle and transport. It is crucial to plan logistics efficiently to ensure timely delivery and proper storage and handling on-site. 3. Welding and fabrication: Steel structures often require complex and time-consuming welding and fabrication processes. It is essential to have proper training and expertise to ensure high-quality work, as any defects can compromise the structural integrity. 4. Weather conditions: Adverse weather conditions such as high winds, extreme temperatures, and heavy rainfall can significantly impact the construction of steel structures. These conditions can delay progress, increase safety risks, and require additional measures for protection against corrosion or damage. 5. Limited site access and space: Steel structures are often constructed in urban areas or on sites with limited access and space. This presents challenges in terms of logistics, material storage, and equipment maneuverability. Careful planning and coordination are necessary to minimize disruptions and optimize construction processes. 6. Coordination with other trades: Steel structures are typically part of larger construction projects involving multiple trades and disciplines. Effective coordination and communication with other contractors, architects, engineers, and subcontractors are essential to ensure seamless integration with other building systems and to avoid delays or conflicts. 7. Quality control and inspections: Adhering to industry standards and codes is crucial for ensuring the quality of steel structures. Regular inspections and quality control measures are necessary to verify the integrity of components, welding, and fabrication processes. Promptly addressing any deficiencies or deviations is essential for maintaining safety and structural soundness. In conclusion, the construction of steel structures requires careful planning, coordination, and expertise. By effectively addressing these common challenges, construction projects can be successfully completed, resulting in safe, durable, and aesthetically pleasing structures.

- Q: What are the different types of steel roofs and skylights used in buildings?

- There are various types of steel roofs used in buildings, including corrugated steel roofs, standing seam steel roofs, and steel shingle roofs. As for skylights, steel-framed skylights are commonly used in buildings, along with steel-supported glass roofs and steel-clad skylights.

- Q: How are steel structures used in oil and gas refineries?

- Due to their exceptional strength, durability, and versatility, steel structures are widely utilized in oil and gas refineries. They play a crucial role in supporting the various components and equipment necessary for refining processes. Storage tanks are a primary application of steel structures in oil and gas refineries. These tanks are typically constructed with steel due to its ability to withstand high pressures and harsh weather conditions. They serve as storage facilities for crude oil, refined petroleum products, and other chemicals involved in the refining process. Furthermore, steel structures are employed to create platforms and walkways that grant access to different areas of the refinery. These platforms are indispensable for maintenance, inspections, and operational activities. Steel's strength ensures the safety of workers and equipment, even in demanding environments. Pipelines, another essential component of oil and gas refineries, heavily rely on steel structures. Steel pipes are renowned for their strength, corrosion resistance, and ability to endure high temperatures and pressures. They are utilized to transport crude oil, natural gas, and various refined products throughout the refinery complex. Moreover, steel structures are utilized in the construction of process units, including distillation towers, reactors, and heat exchangers. These units are crucial for the separation, conversion, and purification of different components in the refining process. Steel's high load-bearing capacity and resistance to heat make it an ideal material for these structures. In conclusion, steel structures are indispensable in oil and gas refineries for a variety of applications. From storage tanks and pipelines to platforms and process units, the strength, durability, and versatility of steel make it a perfect material choice. It ensures the safety, efficiency, and longevity of refinery operations, contributing to the overall success of the industry.

Send your message to us

Sandwichpanel Prefabricated House | Camp House Sandwichpanele

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords