Rusty Steel Sheets - Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

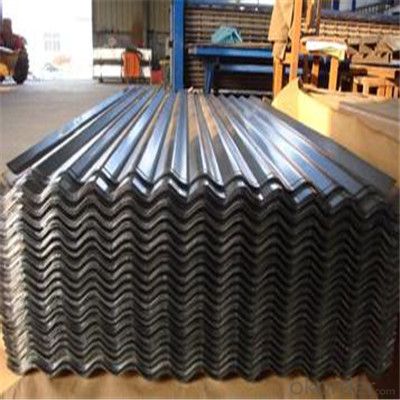

Description of Corrugated Iron Sheet:

Weight of each package: about 4.1mt

Width: 600mm-1250mmWidth tolerance:-0/+3mm

Depth of corrugated: from 23mm to 25mm

Pitch: from 57mm to 59mm

Length: less than 12m

Surface treatment: chromate, oil/unoil, bright finish, spangle

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

(1) Novel and beautiful modeling , rich luster, strong adornment sex, flexible in combination, can express different architectural styles;

(2) Light weight (6 ~ 10 kg/m squared) high strength (yield strength 250 ~ 550 mpa) fine skin stiffness,fine seismic performance of waterproofing agent;

(3) Factory product with high quality

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:What is the difference between a smooth and expanded metal steel sheet?

- A smooth metal steel sheet has a flat surface with no perforations or raised patterns, while an expanded metal steel sheet has a textured surface with small diamond-shaped openings that are created by stretching the metal.

- Q:Can the steel sheets be bent or formed into different shapes?

- Yes, steel sheets can be bent or formed into different shapes using a variety of techniques such as pressing, rolling, or using specialized machinery like hydraulic brakes or metal forming tools.

- Q:Can steel sheets be perforated for ventilation purposes?

- Indeed, ventilation purposes can be achieved through the perforation of steel sheets. Multiple industries and applications frequently employ perforated steel sheets whenever ventilation is necessary. By incorporating perforations into the steel sheets, airflow is enabled while ensuring the material's structural integrity remains intact. The customization of these perforations allows for ventilation requirements to be tailored, encompassing factors like hole size and pattern. Notably, HVAC systems, industrial equipment, architectural endeavors, and acoustic panels, among other applications, greatly benefit from the utilization of perforated steel sheets. This is due to the crucial need for a harmonious equilibrium between ventilation and strength.

- Q:Can the steel sheets be used for roofing purposes?

- Yes, steel sheets can be used for roofing purposes. Steel roofing sheets are a popular choice due to their durability, strength, and resistance to harsh weather conditions. They provide excellent protection against elements such as rain, snow, and hail. Steel roofing sheets are also fire-resistant and can withstand high winds, making them a reliable option for roofing. Additionally, steel sheets are lightweight, which makes them easier to install and reduces the load on the structure. They are available in various designs and colors, allowing for customization according to individual preferences. Overall, steel sheets are a versatile and practical choice for roofing purposes.

- Q:What is the typical yield strength of steel sheets?

- The typical yield strength of steel sheets can vary depending on the grade and type of steel. However, on average, low carbon steel sheets have a yield strength of around 250 MPa (megapascals), while high carbon steel sheets can have a yield strength of up to 800 MPa.

- Q:How do steel sheets handle weathering?

- Steel sheets are designed to handle weathering quite effectively. They are typically coated with a protective layer, such as zinc or a combination of zinc and aluminum, which creates a barrier against moisture and other environmental elements. This coating, known as galvanization, prevents the steel from corroding or rusting when exposed to rain, snow, and other forms of precipitation. In addition to the protective coating, steel sheets are also treated with various chemical processes to enhance their resistance to weathering. These processes may include the application of primers, paints, or sealants that further shield the steel from moisture, UV radiation, and extreme temperature fluctuations. Moreover, the composition of steel itself contributes to its ability to withstand weathering. Steel is an alloy comprised primarily of iron, carbon, and other elements, which gives it inherent strength and durability. This structural integrity allows steel sheets to resist deformation, cracking, or warping that may occur due to weather-related stresses. However, it is important to note that over time, even the most well-protected steel sheets may experience some degree of weathering. Exposure to harsh environmental conditions can gradually degrade the protective coating, leading to the formation of small areas of rust or corrosion. Regular maintenance, such as cleaning, inspecting, and reapplying protective coatings, can help prolong the lifespan of steel sheets and maintain their resistance to weathering.

- Q:What is the average weight of galvanized steel sheets?

- The average weight of galvanized steel sheets can vary depending on their dimensions and thickness. However, a common gauge for galvanized steel sheets is between 18 and 26 gauge, with sizes ranging from 0.036 inches to 0.0179 inches thick. On average, a 18 gauge galvanized steel sheet can weigh approximately 5.625 pounds per square foot, while a 26 gauge sheet may weigh around 3.125 pounds per square foot. It is important to note that these numbers are approximate averages and individual sheets may vary slightly in weight.

- Q:What are the different types of steel sheet surface coatings for corrosion resistance?

- There are several types of steel sheet surface coatings available for corrosion resistance, including galvanized coatings, zinc-rich coatings, aluminum coatings, and organic coatings such as paint or epoxy. Each coating offers unique benefits and application suitability depending on the specific requirements and environmental conditions.

- Q:What is the minimum thickness of a steel sheet?

- The minimum thickness of a steel sheet depends on various factors, including the specific grade of steel being used, the intended application, and the manufacturing process. However, in general, steel sheets can be produced with thicknesses ranging from as thin as 0.4 millimeters (0.016 inches) to several millimeters thick. It is important to note that thinner steel sheets are typically used for applications that require flexibility and lightness, such as automotive body panels or electrical enclosures, while thicker sheets are employed for structural purposes, such as construction materials or heavy machinery components. Ultimately, the minimum thickness of a steel sheet is determined by the specific requirements of the project or application.

- Q:What is the process of manufacturing steel sheets?

- Manufacturing steel sheets encompasses a series of steps. Initially, the necessary raw materials for steel production, including iron ore, coal, and limestone, are acquired. Following this, these materials undergo processing in a blast furnace to generate molten iron. The molten iron is then refined in either a basic oxygen furnace or an electric arc furnace, eliminating impurities and incorporating alloying elements to attain the desired steel composition. Upon completion of the refining process, the steel is cast into slabs or billets, which are subsequently reheated in a furnace until they reach a suitable temperature for rolling. The reheated steel is then fed through a sequence of rolling mills, where it is shaped and its thickness is reduced to form a continuous sheet. The rolling process comprises multiple passes through the mills, gradually diminishing the steel's thickness and enhancing its properties. After the rolling process, the steel sheets are frequently subjected to pickling and treated with various coatings or finishes to enhance their surface quality and resistance to corrosion. Finally, the sheets are cut into specific sizes and may undergo additional processing, such as tempering or annealing, to further enhance their mechanical properties. In summary, the production of steel sheets involves a combination of refining, casting, rolling, and finishing processes to create superior-quality sheets that meet the desired specifications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rusty Steel Sheets - Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords