Mesh Shape Color Coated Steel Coil Orange Peel Shape Color Steel Coil PPGI PPGL PPAL GI GL

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Mesh Shape Color Coated Steel Coil PPGI PPGL PPAL

Product | PPGI/PPGL/PPAL |

Capacity | 10,000 tons/month |

Base material | Hot dipped galvanized steel/Aluminum |

Thickness | 0.10-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Mesh Shape Color Coated Steel Coil PPGI PPGL PPAL

APPLICATION OF OUR PREPAINTED STEEL | ||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit |

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |

Products Show of Mesh Shape Color Coated Steel Coils PPGI PPGL PPAL

Packaging & Delivery

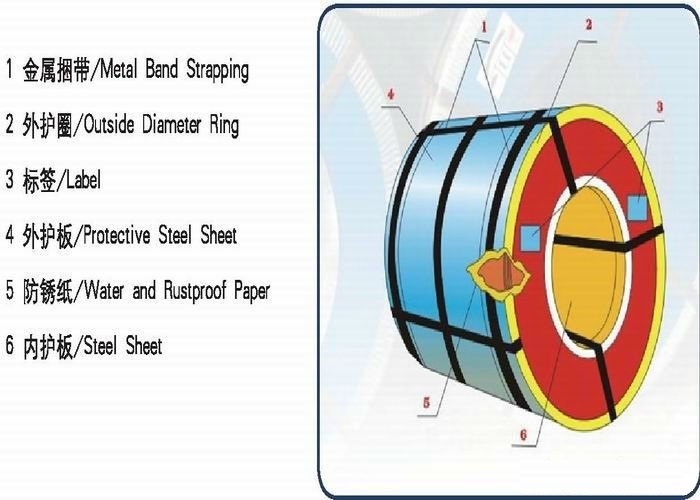

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. |

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . |

3.Having two series producttion line,with the abbual production capacity of 240000 tons. |

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards |

5.Meet with ROHS standard |

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

We are a trading company but we have so many protocol factories and We works as a trading department of these factories. Also We are the shareholders of the factory.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the common size limitations for steel coil production?

- The size limitations for steel coil production can vary based on various factors, including the type of steel used, the manufacturing process, and the available equipment. However, there are generally accepted size limitations in the industry. One primary constraint is the width of the steel coil, which is typically determined by the size of the rolling mill or slitting equipment used in production. Standard widths for steel coil production range from approximately 600 millimeters (23.6 inches) to 2,000 millimeters (78.7 inches). Nonetheless, specialized equipment and processes can achieve widths outside of this range. Another limitation is the thickness of the steel coil, which can be influenced by the type of steel, intended application, and manufacturing capabilities. Common thicknesses for steel coils range from 0.15 millimeters (0.006 inches) to 6 millimeters (0.236 inches). However, specialized equipment and processes may be required to produce thicker or thinner coils. The weight of the steel coil is also an important consideration, typically determined by the capacity of production and handling equipment, as well as transportation limitations. Standard coil weights range from a few hundred kilograms to several tons. However, larger equipment or dividing the coil into smaller coils can enable the production of coils that exceed these limits. In addition to width, thickness, and weight, there may also be limitations on the length of the steel coil. This can be influenced by factors such as the size of the production line, handling and transportation capabilities, and customer requirements. Standard coil lengths typically range from a few meters to several tens of meters. However, specialized equipment and processes can produce longer coils. It is important to note that these size limitations are not fixed and can vary depending on project or customer requirements. Manufacturers often collaborate closely with customers to determine the optimal size limitations for their steel coil production, ensuring the final product meets desired specifications.

- Q: i cant find this stuff about steel:conductivitystrengthcorrosion resistancecommon applicationsif you know of any interesting facts, i could use those 2!thanx!

- go okorder and search for steel.......

- Q: where can i find information online about steel residential homes that use solar energy?

- Steel okorder

- Q: Like 49ers. Pittsburgh have long history of steel industry?

- Yes, short and simple

- Q: How are steel coils inspected for defects after rewinding?

- Steel coils are inspected for defects after rewinding through a thorough visual examination and various non-destructive testing techniques such as ultrasonic testing, magnetic particle inspection, and eddy current testing. These methods help identify any surface defects, internal flaws, or deviations in dimensions, ensuring the quality and integrity of the steel coils.

- Q: Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- steel, it will take you way to long to mine mithril ore, and all the coal. also if you make steel plate bodies they actually sell becuase people use it to make steel titian pouches

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings for various purposes, primarily for structural support. These coils are typically used to create steel frames, beams, and columns that provide strength and stability to the structure. Additionally, steel coils are also used in the production of roofing materials, wall cladding, and reinforcement bars, which further enhance the durability and safety of the building.

- Q: How are steel coils used in the manufacturing of machinery?

- Steel coils are used in the manufacturing of machinery as they provide a reliable and durable material for various components and structures. These coils are often shaped, cut, and formed into desired parts such as gears, shafts, frames, and supports. The high strength and versatility of steel coils allow them to withstand heavy loads and harsh conditions, ensuring the machinery's efficiency and longevity.

- Q: How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials by being unwound and flattened to create the wire used for fencing. The steel wire is then further processed and shaped into different forms, such as chain link or barbed wire, to meet specific fencing needs.

- Q: Is a steel plate the same as a steel coil?

- You must have an open book and a flat plate, and it is a little bit harder to cut the parts than the plate.

Send your message to us

Mesh Shape Color Coated Steel Coil Orange Peel Shape Color Steel Coil PPGI PPGL PPAL GI GL

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords