Printed Color Coated Steel Coil PPGI PPGL PPAL GL GI AL PPGIPPGL

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Printed Color Coated Steel Coil PPGI PPGL PPAL

Product | PPGI/PPGL/PPAL |

Capacity | 10,000 tons/month |

Base material | Hot dipped galvanized steel/Aluminum |

Thickness | 0.10-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Printed Color Coated Steel Coil PPGI PPGL PPAL

APPLICATION OF OUR PREPAINTED STEEL | ||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit |

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |

Products Show of Printed Color Coated Steel Coil PPGI PPGL PPAL

Packaging & Delivery

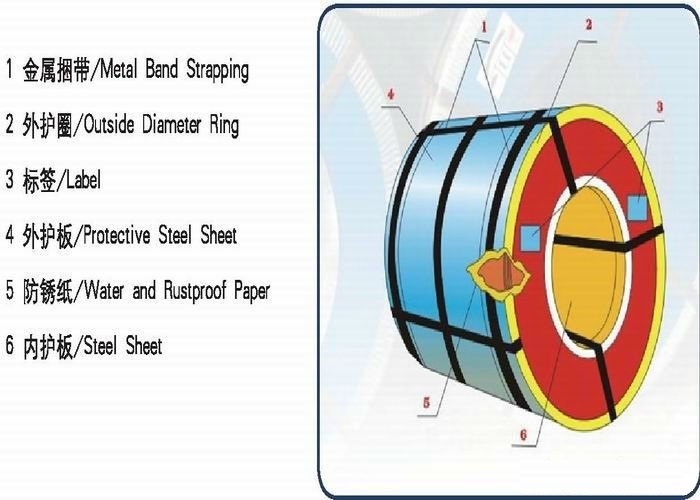

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. |

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . |

3.Having two series producttion line,with the abbual production capacity of 240000 tons. |

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards |

5.Meet with ROHS standard |

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

We are a trading company but we have so many protocol factories and We works as a trading department of these factories. Also We are the shareholders of the factory.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the quality standards for steel coil manufacturing?

- The quality standards for steel coil manufacturing typically include factors such as dimensional accuracy, surface finish, mechanical properties, chemical composition, and adherence to industry-specific standards set by organizations like ASTM or ISO.

- Q: How are steel coils used in the manufacturing of agricultural silos?

- Steel coils are used in the manufacturing of agricultural silos by being formed and shaped into corrugated sheets, which are then assembled into the walls of the silo. The strength and durability of the steel coils ensure that the silo can withstand the weight of the stored grains and withstand external pressures.

- Q: How do steel coils contribute to the agricultural sector?

- Steel coils contribute to the agricultural sector in various ways. Firstly, steel coils are used in the manufacturing of agricultural machinery and equipment such as tractors, harvesters, and irrigation systems. These machines are essential for efficient farming operations, helping farmers increase productivity and reduce labor costs. The strength and durability of steel coils ensure that the machinery can withstand the harsh conditions of the agricultural environment. Additionally, steel coils are used in the construction of storage facilities and warehouses for storing agricultural products. These structures need to be strong and resistant to external elements to protect the crops from damage. Steel coils provide the necessary strength and stability required for constructing these storage facilities, ensuring the safe storage of agricultural produce. Furthermore, steel coils are used in the fabrication of fencing and other agricultural infrastructure. Fencing is crucial in protecting crops from animals and preventing trespassing. Steel coils provide a robust material for fencing, ensuring the security and protection of agricultural lands. Moreover, steel coils are utilized in the production of irrigation pipes and systems. Efficient irrigation is vital for the growth and yield of crops, especially in areas with limited water resources. Steel coils are used to manufacture pipes that can withstand high pressure and are resistant to corrosion, ensuring the efficient distribution of water throughout the agricultural fields. In summary, steel coils play a significant role in the agricultural sector by providing the necessary materials for manufacturing machinery, constructing storage facilities, fencing, and irrigation systems. The strength, durability, and resistance to harsh conditions make steel coils an essential component in enhancing agricultural productivity, protecting crops, and ensuring efficient farming practices.

- Q: When i was 15 i got caught steeling at Super A yes i know i cant believe it. They didnt call the cops or anything they released me to my aunt they took my name and adress and everythimg they said it wouldnt be on my record. But I'm not so sure. Will it be on my record if they didn't call the cops?i live in california. Is there any way i can check my record?

- Steeling? What's that? Did you take a piece of steel and weld it? I am confused?

- Q: How are steel coils used in the manufacturing of industrial machinery?

- Steel coils are used in the manufacturing of industrial machinery as they serve as the primary raw material for various components such as frames, casings, gears, and structural supports. These coils are typically cut, shaped, and welded to create the desired machine parts, ensuring strength, durability, and precision in the final product.

- Q: They say it's some six times stronger than steel. need some explanation.

- Most importantly, spider silk is extremely lightweight: a strand of spider silk long enough to circle the Earth would weigh less than 500 grams (18 oz). Spider silk is also especially ductile, able to stretch up to 140% of its length without breaking. It can hold its strength below ?40 °C. This gives it a very high toughness (or work to fracture), which equals that of commercial polyaramid (aromatic nylon) filaments, which themselves are benchmarks of modern polymer fiber technology. What this means in regard to what you have heard is that if you compared the tensile strength (type 'tensile strength' on wikipedia if you do not know what it means) of spider silk and a strand of steel at the same thickness, the silk would have a higher tensile strength than many grades of steel, upto that of high grade steel - of which they are about the same.

- Q: How are defects in steel coils repaired?

- Defects in steel coils are repaired through various methods depending on the type and severity of the defect. Common repair techniques include grinding, welding, soldering, or using heat treatment processes to correct the defects. The specific approach is determined by professionals after assessing the nature of the defect and considering the desired quality and performance standards of the steel coils.

- Q: How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as the primary material for producing pipes and tubing. These coils are processed and formed into various shapes and sizes to create the necessary components, such as the main exhaust pipe and smaller sections for mufflers and catalytic converters. The steel's strength and durability make it an ideal choice for withstanding the high temperatures and corrosive nature of exhaust gases, ensuring the longevity and functionality of the system.

- Q: What are the common surface treatments for galvanized steel coils?

- The common surface treatments for galvanized steel coils include passivation, chromate coating, and oiling. Passivation is a process where a thin layer of protective material, such as zinc phosphate or chromate, is applied onto the galvanized steel surface. This layer helps to enhance the corrosion resistance of the steel by providing a barrier against moisture and atmospheric elements. Passivation also improves the adhesion of subsequent coatings or paints that may be applied to the steel. Chromate coating, also known as chromating or chromate conversion coating, involves the application of a thin layer of chromate onto the galvanized steel surface. This coating provides an additional layer of protection against corrosion and improves the appearance of the steel. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is another common surface treatment for galvanized steel coils. This involves the application of a thin layer of oil onto the surface of the steel, which helps to prevent the formation of rust and corrosion during storage and transportation. Oiling also provides temporary protection against moisture and other environmental factors until the steel is further processed or used in its final application. These surface treatments are commonly used to enhance the performance, durability, and appearance of galvanized steel coils, ensuring that they can withstand harsh conditions and maintain their quality over time.

- Q: When maintaining a japanese knife: Is a honing steel still necessary if I have a fine 3000/8000 grit whetstone?which do you prefer?

- A steel is to clean off an edge and remove any bends on the bevel, it is not directly for sharpening as it removes no material from the knife (or should not). A whetstone, however fine, does remove material. A steel to maintain an edge, a stone to restore an edge. They are different items for different purposes.

Send your message to us

Printed Color Coated Steel Coil PPGI PPGL PPAL GL GI AL PPGIPPGL

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords