Aluzinc Steel Sheet for Roofing with Prime Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluzinc Steel Sheets Description:

Hot-dip aluzinc steel sheet is substrated on cold rolled steel(CRC) in various strength and specification. Coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• Excellent corrosion resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

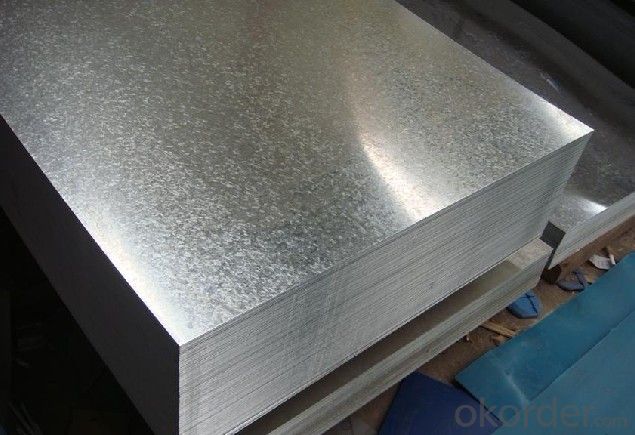

3. Aluzinc Steel Sheets Images

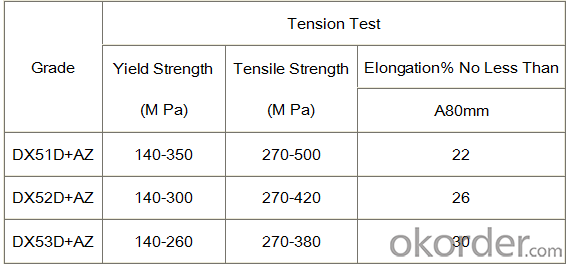

4.Aluzinc Steel Sheets Specification

Thickness: 0.3-0.7mm

Width: 914-1250mm

Inner Diameter: 508-610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Available Surface Treatment: Passivating & Oiling & AFP & Filming

5.FAQ of Aluzinc Steel Sheets

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can steel sheets be used in corrosive environments?

- Corrosive environments necessitate careful consideration of the type of steel used and appropriate protective measures. Stainless steel, for instance, is known for its exceptional resistance to corrosion and ability to withstand harsh conditions. It contains chromium, which creates a protective oxide layer on the surface, preventing corrosion. Alternatively, galvanized steel involves applying a layer of zinc to the surface, forming a protective barrier against corrosion. Furthermore, one can enhance the resistance of steel sheets to corrosive elements by applying various coatings like epoxy, polyurethane, or paint. The selection of the right steel grade and protective coatings is crucial and should be based on the specific corrosive environment to ensure long-lasting performance. Regular inspections and maintenance are also imperative to promptly identify and address any potential signs of corrosion.

- Q: Can steel sheets be used in architectural or decorative applications?

- Yes, steel sheets can be used in architectural or decorative applications. Steel sheets offer durability, versatility, and a sleek aesthetic that make them suitable for various architectural and decorative purposes such as cladding, roofing, wall panels, and interior design elements.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets are known for their exceptional weather resistance properties. Due to their composition and protective coatings, steel sheets are highly resistant to various weather conditions such as rain, snow, and wind. They have the ability to withstand extreme temperatures, both hot and cold, without any significant deterioration or damage. Additionally, steel sheets are also highly resistant to corrosion, making them an ideal choice for outdoor applications and areas with high humidity or saltwater exposure. The weather resistance of steel sheets helps to ensure their longevity and durability, making them a reliable option for various construction and industrial purposes.

- Q: Stainless steel drawing plate, polishing plate, mirror panels of the three differences

- Drawing process will to some extent lose the thickness of stainless steel plate, usually at 0.1~0.2mm. In addition, because the human body, especially the palm has a relatively strong oil and sweat secretion, stainless steel wire drawing board often hand touch will leave a more obvious fingerprints, regular scrub.

- Q: What is the standard size of steel sheets?

- The standard size of steel sheets can vary depending on the specific application and industry. However, a common standard size for steel sheets is 4 feet by 8 feet, also known as 48 inches by 96 inches.

- Q: What are the common sizes of steel sheets available in the market?

- The common sizes of steel sheets available in the market vary, but some standard sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sizes are widely used in various industries and can be easily found in steel suppliers or hardware stores.

- Q: Are steel sheets suitable for harsh weather conditions?

- Yes, steel sheets are highly suitable for harsh weather conditions. Steel is known for its durability and strength, making it an ideal material for withstanding extreme weather conditions such as high winds, heavy rain, snow, and even hail. Steel sheets are designed to be resistant to corrosion, rust, and degradation caused by prolonged exposure to harsh weather, making them long-lasting and reliable in any climate. Additionally, steel sheets can be coated with protective finishes, such as galvanized or painted coatings, to further enhance their resistance to weathering. This makes steel sheets a popular choice for various applications in harsh weather-prone areas, including roofing, siding, and outdoor structures, as they provide excellent protection and structural integrity even in the toughest weather conditions.

- Q: Are steel sheets non-magnetic?

- No, steel sheets are generally magnetic.

- Q: Can steel sheets be used for shipbuilding?

- Absolutely, shipbuilding can definitely make use of steel sheets. In reality, steel stands as one of the most frequently employed materials in shipbuilding owing to its exceptional strength, durability, and resistance to corrosion. It is typical to employ steel sheets for the construction of a ship's hull, decks, and other structural elements. The superior tensile strength of steel equips ships with the ability to withstand the harsh conditions of the ocean, including heavy waves and extreme weather. Furthermore, the ease of fabrication and welding of steel sheets renders them an ideal choice for the construction of large and intricate ship structures. On the whole, steel sheets emerge as a dependable and efficient option for shipbuilding.

- Q: Are steel sheets available in different patterns or textures?

- Indeed, one can find steel sheets in a multitude of patterns and textures. Although conventional steel sheets possess a smooth and unadorned appearance, there exists a wide array of alternatives featuring diverse patterns and textures. These patterns can be skillfully embossed, delicately etched, or expertly brushed onto the surface of the steel, thereby enhancing its aesthetic appeal. Some frequently encountered patterns include diamond, checker, or grid patterns, while textures can range from a subdued and velvety matte finish to a more lustrous and reflective surface. The availability of these diverse patterns and textures bestows upon designers a greater degree of flexibility, rendering them suitable for a myriad of applications, such as architectural endeavors, interior design projects, or ornamental components in furniture and fixtures.

Send your message to us

Aluzinc Steel Sheet for Roofing with Prime Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords