Reinforced Welded Mesh Panel Black Galvanized Construction Materials with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Reinforced Welded Mesh Panel Description:

Welded Wire Mesh Panel is made of superior quality welded mesh panel with flat even surface, firm structure, be used extensively in building, food, agriculture and so on.Smooth and trim mesh surface, solid and uniform structure and superior integral performance, it won't loosen even subject to local cutting or pressure, It has the characteristics of corrosion-resisting and oxidation resisting.

Reinforced Welded Mesh Panel is extensively used in industry and agriculture construction, transportation and mining for all such purposes as poultry houses, egg baskets, runway enclosures, floor heating draining rack, fruit drying screen, fence, fruit drying screen, fence and other industries

2.Main Features of Reinforced Welded Mesh Panel:

• Antirust

• Durable

• Nice Visual

• User-friendly

• Solid

• versatile

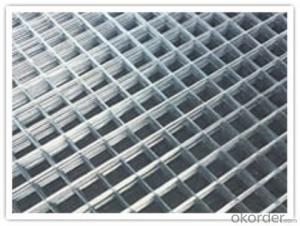

3.Reinforced Welded Mesh Panel Images

4.Reinforced Welded Mesh Panel Specification

Product Code | Std Unit | Longitudinal Wires | Cross Wires | Mass(kg) | Dimensions(m) |

SL52 | sheet | 10×4.77@200+4×4@100 | 30×4.77@200 | 21 | 6×2.4 |

SL62 | sheet | 10×6@200+4×4.77@100 | 30×6@200 | 33 | 6×2.4 |

SL72 | sheet | 10×6.75@200+4×4@100 | 30×6.75@200 | 41 | 6×2.4 |

SL81 | sheet | 25×7.6@100 | 60×7.6@200 | 105 | 6×2.4 |

SL82 | sheet | 10×7.6@200+4×5.37@100 | 30×7.6@200 | 52 | 6×2.4 |

SL92 | sheet | 10×8.6@200+4×6@100 | 30×8.6@200 | 66 | 6×2.4 |

SL102 | sheet | 10×9.5@200+4×6.75@100 | 30×9.5@200 | 80 | 6×2.4 |

× Diameter (mm) × Spacing (mm) | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

We are one of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional Reinforced Welded Mesh Panel factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is Assortments of Reinforced Welded Mesh Panel?

Galvanized Welded Wire Mesh Panel

Electro galvanized welded wire mesh panel

Hot Dipped Galvanized welded mesh panel

PVC Coated Welded Wire Mesh panel

Stainless steel welded wire mesh panel

③How long can we receive the product after purchase?

In the purchase of Reinforced Welded Mesh Panel within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: How is steel wire mesh maintained?

- Steel wire mesh is maintained by regularly inspecting it for any signs of damage or corrosion. Any rust or corrosion should be removed using a wire brush or sandpaper. Additionally, the mesh should be cleaned periodically to remove dirt, debris, and any other contaminants that may accumulate on its surface. It is also important to avoid placing heavy objects on the mesh or subjecting it to excessive force or stress, as this could potentially damage or deform the wires.

- Q: Can steel wire mesh be used for erosion control and slope stabilization?

- Erosion control and slope stabilization can be achieved using steel wire mesh. This material is commonly utilized for these purposes due to its robustness, longevity, and ability to withstand harsh environmental conditions. Typically, the mesh is installed on slopes or banks to maintain stability and prevent soil erosion. By acting as a barrier, it hinders the movement of soil particles while allowing water to pass through. To ensure a secure installation, the steel wire mesh is usually anchored to the ground using stakes or anchors. This reinforcement strengthens the slope and prevents further erosion. Furthermore, combining the steel wire mesh with vegetation can enhance its effectiveness. In conclusion, steel wire mesh is a dependable and efficient solution for erosion control and slope stabilization applications.

- Q: What are the disadvantages of using steel wire mesh?

- There are several disadvantages of using steel wire mesh, which should be taken into consideration before opting for this material. One of the main disadvantages is its susceptibility to corrosion. Steel wire mesh is prone to rusting, especially when exposed to moisture or corrosive elements. This can significantly reduce its lifespan and structural integrity. Regular maintenance and protective coatings may be required to prevent or slow down the corrosion process. Another drawback is the potential for sharp edges. Steel wire mesh is made up of interconnected wires, which can have sharp ends or protrusions. This can pose a safety hazard, especially if the mesh is used in areas where people might come into contact with it. Extra precautions should be taken to ensure the edges are properly finished or protected to avoid any injuries. Additionally, steel wire mesh is not suitable for applications requiring high transparency or visibility. Due to its grid-like structure, it may obstruct the view and limit the passage of light and air. This can be a disadvantage in situations where unobstructed vision or adequate airflow is desired. Moreover, steel wire mesh is relatively heavy and can be challenging to install or manipulate. Its weight can make it difficult to handle and transport, requiring additional labor or equipment. Furthermore, the rigidity of the material makes it less flexible compared to other alternatives, making it less adaptable to certain project requirements. Lastly, steel wire mesh can be more expensive than other materials. The cost of the steel, manufacturing processes, and specialized equipment required for installation can contribute to its higher price. This can make it less cost-effective for some projects, especially when there are more affordable alternatives available. In conclusion, while steel wire mesh offers several advantages, including durability and strength, it also has its disadvantages. These include susceptibility to corrosion, sharp edges, limited visibility, difficulty in handling, and higher costs. Assessing these drawbacks alongside the specific needs of the project is crucial in determining whether steel wire mesh is the most suitable option.

- Q: Can steel wire mesh be used for mining?

- Yes, steel wire mesh can be used for mining. It is commonly used as a reinforcement material in underground mining operations to provide support and prevent rockfalls or collapses. The mesh is installed to line the walls, ceiling, and floor of the mine to create a safer working environment for miners.

- Q: Can steel wire mesh be used for reinforcement in concrete slabs?

- Yes, steel wire mesh can be used for reinforcement in concrete slabs. It helps to enhance the strength and durability of the concrete by providing structural support and preventing cracking or failure.

- Q: Can steel wire mesh be used for stone retaining walls?

- Yes, steel wire mesh can be used for stone retaining walls. It can provide added strength and stability to the structure, helping to prevent the stones from shifting or collapsing. The wire mesh is typically installed within the wall, acting as a reinforcement and holding the stones together.

- Q: Does steel wire mesh provide good ventilation?

- Good ventilation is provided by steel wire mesh. The mesh's open structure allows for unrestricted airflow, making it an excellent choice for situations that require ventilation. Whether it is utilized in windows, fences, or other constructions, the steel wire mesh permits the circulation of fresh air while ensuring security and protection. Moreover, the durability and strength of steel make it a dependable choice for long-term ventilation requirements. All in all, steel wire mesh is a successful solution for achieving superior airflow and ventilation in diverse environments.

- Q: What are the different edge finishing options available for steel wire mesh?

- Steel wire mesh offers various edge finishing options to meet specific requirements and applications. These options comprise: 1. Selvage Edge: The most common and cost-effective choice is twisting the wire ends to form a loop or hook. This method prevents unraveling and strengthens the mesh. 2. Welded Edge: Heat and pressure are utilized to weld the wire ends, creating a durable and sturdy edge that prevents fraying. Commonly used in industrial applications for enhanced strength and stability. 3. Serged Edge: The wire ends are wrapped with a separate wire or thread, stitched along the edge of the mesh. Serged edges reinforce the mesh and protect it from damage or unraveling. 4. Folded Edge: Wire ends are folded back onto the mesh, resulting in a clean and smooth edge. Ideal for applications where aesthetics and a tidy appearance are crucial. 5. PVC Coating: Some steel wire meshes can be coated with PVC (Polyvinyl Chloride) to provide both protection and a decorative edge finish. This coating enhances the mesh's appearance and prevents corrosion and rusting. 6. Hemmed Edge: This method involves folding the wire ends back onto themselves and stitching or hemming them together. Hemmed edges add strength and prevent fraying or unraveling of the mesh. To select the appropriate edge finishing option for steel wire mesh, it is essential to consider specific requirements such as strength, durability, aesthetics, and budget.

- Q: Is steel wire mesh suitable for food processing or packaging?

- Yes, steel wire mesh is suitable for food processing or packaging in certain instances. Steel wire mesh is known for its strength, durability, and resistance to corrosion, making it an ideal material for applications in the food industry where hygiene and safety are paramount. In food processing, steel wire mesh can be used for various purposes such as sieving, filtering, and straining. Its fine mesh structure allows for the separation of solids and liquids, ensuring that only the desired components are retained. This is particularly useful in processes like sifting flour, straining liquids, or removing impurities from ingredients. Furthermore, steel wire mesh can be utilized for packaging food products. Its sturdy and rigid construction provides excellent protection and containment for items such as fruits, vegetables, or seafood. The mesh design allows for proper air circulation, preventing spoilage and maintaining product freshness. However, it is important to note that not all steel wire mesh is suitable for direct contact with food. It is crucial to choose a mesh that is made from food-grade stainless steel, specifically designed to meet health and safety regulations. Food-grade stainless steel is non-reactive, non-toxic, and resistant to bacterial growth, ensuring that it does not contaminate the food. Moreover, regular cleaning and maintenance are essential to prevent the buildup of dirt, grease, or food particles, which can compromise the hygiene and safety of the mesh. Periodic inspections and replacement of worn-out or damaged mesh are also necessary to maintain its effectiveness and prevent any risk of contamination. In conclusion, steel wire mesh can be a suitable material for food processing or packaging, provided that it is made from food-grade stainless steel and is properly cleaned and maintained. It offers strength, durability, and hygiene, making it a valuable asset in the food industry.

- Q: Can steel wire mesh be used for anti-slip surfaces and walkways?

- Steel wire mesh is a versatile option for anti-slip surfaces and walkways. With its durability and strength, it offers exceptional traction and grip. This makes it perfect for establishing anti-slip surfaces. The mesh's open structure allows water, dirt, and debris to pass through, reducing the chance of slipping and improving safety. Furthermore, steel wire mesh is resistant to corrosion, making it suitable for outdoor use where moisture is present. It can be easily installed on stairs, ramps, bridges, and walkways to enhance traction and prevent accidents. In summary, steel wire mesh is a dependable and efficient solution for establishing anti-slip surfaces and walkways.

Send your message to us

Reinforced Welded Mesh Panel Black Galvanized Construction Materials with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords