Galvanized Hexagonal Wire Netting-3/4 Inch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

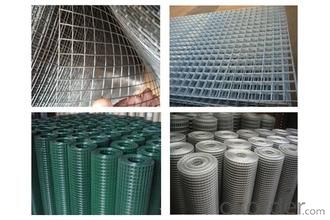

Pictures of Galvanized Hexagonal Wire Mesh

Specification of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh-Normal Twist |

| Mesh OpeningWire ThicknessWidthinchmmbwgmminchm3/81027; 26; 25; 24; 230.40-0.6312-480.3-1.21/21327; 26; 25; 24; 23; 22; 21; 200.40-0.8812-800.3-2.05/81627; 26; 25; 24; 23; 22; 21; 200.40-0.8812-480.3-1.23/41927; 26; 25; 24; 23; 22; 21; 200.40-0.8812-800.3-2.012527; 26; 25; 24; 23; 22; 21; 200.40-0.8812-800.3-2.01-1/43024; 23; 22; 21; 20; 19; 180.56-1.2512-480.3-1.21-1/24023; 22; 21; 20; 19; 180.63-1.2512-800.3-2.025023; 22; 21; 20; 19; 18; 170.63-1.4712-800.3-2.037523; 22; 21; 20; 19; 18; 17; 16; 150.63-1.8312-800.3-2.0410016; 15; 14; 13; 121.65-2.7720-1600.5-4.0 |

Galvanized Hexagonal Wire Mesh-Revise Twist |

| Mesh OpeningWire ThicknessWidthinchmmbwgmminchm12525; 24; 23; 22; 21; 20; 19; 180.51-1.2512-800.3-2.01-1/43025; 24; 23; 22; 21; 20; 19; 180.51-1.2512-800.3-2.01-1/24025; 24; 23; 22; 21; 20; 19; 180.51-1.2512-800.3-2.025025; 24; 23; 22; 21; 20; 19; 18; 170.51-1.4712-800.3-2.037523; 22; 21; 20; 19; 18; 170.63-1.4712-800.3-2.0 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment Galvanized Hexagonal Wire Mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How is steel wire mesh used in reinforcement of hospitals?

- Steel wire mesh is used in the reinforcement of hospitals by providing structural support to concrete elements such as walls, columns, and beams. It helps to enhance the strength and durability of these structures, making them more resistant to seismic activities or other external forces. Additionally, steel wire mesh can be used to reinforce the flooring and roofing systems of hospitals, ensuring their stability and safety.

- Q: How is steel wire mesh used in reinforcement of power plants and energy facilities?

- Due to its exceptional strength and durability, steel wire mesh is commonly employed in the reinforcement of power plants and energy facilities. It is primarily used in concrete structures to enhance their overall structural integrity and provide additional reinforcement. One of the primary uses of steel wire mesh in these facilities is in the construction of reinforced concrete walls and slabs. These structures must withstand high pressures, vibrations, and extreme temperatures. By incorporating steel wire mesh within the concrete, the load is distributed more effectively, preventing crack propagation and improving the strength and resilience of the structures. Steel wire mesh is also crucial for reinforcing concrete foundations, particularly in areas with weak soil conditions or when the load-bearing capacity needs to be increased. It improves the stability and load-carrying capacity of the foundations by providing additional tensile strength to counteract potential movements or settling. Another important application of steel wire mesh is in the reinforcement of concrete tunnels and pipelines within power plants and energy facilities. These structures carry high-pressure fluids or gases, and failure can have catastrophic consequences. Steel wire mesh reinforces the concrete, preventing cracks and ensuring the long-term durability and structural integrity of these critical components. Furthermore, steel wire mesh is used in the construction of concrete slabs and floors in power plants and energy facilities. These areas are subjected to heavy loads, frequent machinery movement, and exposure to chemicals or extreme temperatures. Reinforcing the concrete with steel wire mesh increases its load-bearing capacity, prevents cracking, and enhances resistance to wear and tear. Overall, steel wire mesh plays a vital role in the reinforcement of power plants and energy facilities. It provides enhanced strength, durability, and resistance to various external influences, ensuring the long-term stability and safety of these structures. This allows them to operate efficiently and reliably for many years.

- Q: Can steel wire mesh be used for acoustic insulation?

- Yes, steel wire mesh can be used for acoustic insulation. It can effectively reduce sound transmission when combined with other materials such as acoustic foam or other sound-absorbing materials. The mesh helps to block and dampen sound waves, making it a suitable option for acoustic insulation in various applications.

- Q: Can steel wire mesh be used for creating partitions or dividers?

- Yes, steel wire mesh can be used for creating partitions or dividers. Steel wire mesh is a versatile material that can be easily shaped and installed to create partitions or dividers in various settings such as homes, offices, or industrial spaces. It provides a sturdy and durable solution for dividing spaces while still allowing visibility and airflow. Steel wire mesh partitions or dividers can be customized to fit specific dimensions and can be combined with other materials such as wood or glass to create a more aesthetically pleasing design. Additionally, steel wire mesh partitions offer the advantage of being easily reconfigurable, allowing for flexible space management.

- Q: Is steel wire mesh easy to clean and maintain?

- Yes, steel wire mesh is generally easy to clean and maintain. It can be easily wiped down or hosed off to remove dirt, dust, or debris. Additionally, its durable and corrosion-resistant nature makes it relatively low-maintenance.

- Q: Can steel wire mesh be used for creating safety nets or fall protection systems?

- Yes, steel wire mesh can be used for creating safety nets or fall protection systems. Steel wire mesh is a strong and durable material that can provide a reliable barrier to prevent falls or accidents in various applications. It is commonly used in construction sites, industrial settings, and even in sports facilities to create safety nets and fall protection systems. The mesh's interwoven design and high tensile strength make it capable of withstanding heavy impact and distributing the force of a fall, thereby minimizing the risk of injury. Additionally, steel wire mesh is resistant to corrosion and can withstand harsh weather conditions, making it suitable for outdoor use. Overall, steel wire mesh is an effective and versatile material for creating safety nets and fall protection systems.

- Q: How does steel wire mesh perform in vibration resistance?

- Steel wire mesh performs well in vibration resistance due to its high tensile strength and durability. The interlocking structure of the mesh effectively absorbs and disperses vibrations, making it an ideal choice for applications that require stability and minimal movement under dynamic loads.

- Q: How is steel wire mesh used in reinforcement of landscaping projects?

- Steel wire mesh is commonly used in the reinforcement of landscaping projects to provide structural support and stability. It is often used to reinforce retaining walls, concrete pathways, and garden beds, preventing them from shifting or collapsing under pressure. The mesh is typically installed within these structures, acting as a reinforcement to distribute the weight and increase their overall strength. Additionally, steel wire mesh can also be used to prevent soil erosion by securing it in place, allowing for better drainage and preventing the loss of topsoil.

- Q: What are the load-bearing capabilities of steel wire mesh?

- The load-bearing capabilities of steel wire mesh are determined by various factors such as the diameter and strength of the wire used, the spacing and configuration of the mesh, and the structural support it receives. Generally, steel wire mesh has excellent load-bearing capabilities due to its inherent strength and rigidity. The diameter of the wire used in the mesh plays a crucial role in determining its load-bearing capacity. Thicker wires can withstand higher loads compared to thinner wires. Additionally, the strength of the wire material also affects its load-bearing capabilities. Steel wire, known for its high tensile strength, provides superior load-bearing capacity compared to other materials. The spacing and configuration of the mesh also impact its load-bearing capabilities. Mesh with smaller openings and closer wire spacing can distribute and support heavier loads more effectively. Furthermore, the structural support provided to the mesh, such as framing or reinforcement, enhances its load-bearing capacity. Proper installation and securing methods ensure that the mesh can withstand the intended load without deformation or failure. It is important to note that load-bearing capabilities can vary depending on the specific application and requirements. Load calculations, engineering analysis, and adherence to relevant building codes and standards are necessary to determine the exact load-bearing capabilities of steel wire mesh in a given scenario. Overall, steel wire mesh is widely recognized for its robust load-bearing capabilities, making it a popular choice in various industries, including construction, mining, agriculture, and infrastructure development.

- Q: What are the weight and density of steel wire mesh?

- The weight and density of steel wire mesh can vary depending on the specific type and thickness of the mesh. However, generally speaking, steel wire mesh has a higher density and weight compared to other materials like aluminum or plastic mesh. The weight and density can be calculated by measuring the dimensions of the mesh and using the density of steel, which is approximately 7850 kg/m³.

Send your message to us

Galvanized Hexagonal Wire Netting-3/4 Inch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords