High Quality 304 Stainless Steel Wire Mesh

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

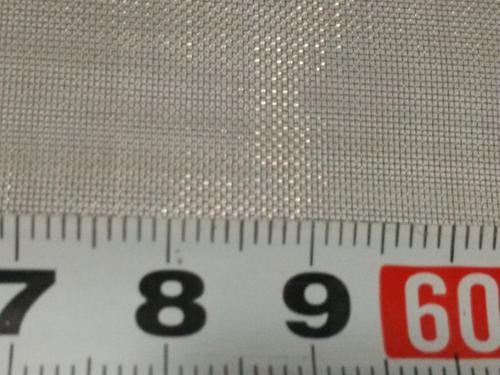

60 Mesh Stainless Steel Wire Mesh

Material: 304 stainless steel wire

Wire DIameter: 0.12mm

Mesh: 60 mesh

Width: 1 m

Length: 30 m/roll

Packing: waterproof paper

MOQ: 1 square meter

Popular Specifications Of Stainless Steel Wire Mesh

- Q: How does steel wire mesh perform in high-tension applications?

- Steel wire mesh performs very well in high-tension applications due to its inherent strength and durability. The steel wires that make up the mesh are designed to withstand high levels of tension without deformation or breakage. This makes it ideal for applications where there is a need for a strong and reliable material to contain or support high-tension loads. In high-tension applications, such as in construction, infrastructure, or industrial settings, steel wire mesh can be used for a variety of purposes. It can be used as a reinforcement material in concrete structures to provide added strength and prevent cracking under high tension. It can also be used as a safety barrier or fencing material to contain or secure areas subjected to high tension forces. The performance of steel wire mesh in high-tension applications is further enhanced by its ability to distribute and absorb tension forces evenly across its surface. This helps to minimize the concentration of stress points, reducing the risk of failure or damage. Additionally, the interlocking nature of the mesh design provides added stability and rigidity, ensuring that it can withstand high-tension loads over an extended period of time. Furthermore, steel wire mesh is highly resistant to corrosion, which is crucial in high-tension applications where exposure to moisture or harsh environments is common. This corrosion resistance ensures that the mesh retains its strength and integrity, even in demanding conditions. Overall, the performance of steel wire mesh in high-tension applications is exceptional. Its strength, durability, even tension distribution, and corrosion resistance make it a reliable and effective choice for various industries and applications where high-tension forces are present.

- Q: Can steel wire mesh be used for construction?

- Yes, steel wire mesh can be used for construction. It is a versatile material that offers various benefits in construction projects. Steel wire mesh is commonly used for reinforcing concrete structures, such as foundations, walls, and slabs, as it provides added strength and durability. It helps to distribute the load evenly, minimizing cracks and improving the overall structural integrity of the construction. Moreover, steel wire mesh can also be used in construction for other purposes, such as forming partitions, creating fences, and providing security. Its high tensile strength, corrosion resistance, and flexibility make it suitable for various construction applications.

- Q: Can steel wire mesh be used for gabion baskets?

- Yes, steel wire mesh can be used for gabion baskets. Gabion baskets are typically made from galvanized steel wire mesh, which provides strength, durability, and resistance to corrosion. The wire mesh is woven into a mesh pattern to create a flexible yet sturdy structure for retaining walls, erosion control, and other civil engineering applications.

- Q: Is steel wire mesh suitable for waste incineration?

- Yes, steel wire mesh is suitable for waste incineration. It is a strong and durable material that can withstand high temperatures, making it an ideal choice for containing and separating waste during the incineration process. Additionally, the mesh structure allows for proper airflow, ensuring efficient combustion and reducing the risk of clogging.

- Q: How is steel wire mesh used in the mining industry?

- Steel wire mesh is commonly used in the mining industry for various applications. It is primarily used for reinforcing tunnels and shafts to provide structural stability and prevent collapse. The mesh is also used as a safety measure to prevent rockfalls or debris from falling onto workers. Additionally, steel wire mesh is utilized for creating screens and filters that separate valuable minerals from unwanted materials during the ore extraction process. Overall, steel wire mesh plays a critical role in ensuring the safety and efficiency of mining operations.

- Q: How does steel wire mesh perform in terms of airflow?

- Due to its open design, steel wire mesh exhibits excellent airflow performance. The interlaced arrangement of the wires enables easy passage of air through the mesh, thereby promoting optimal ventilation. Consequently, it proves to be an ideal material for applications that necessitate efficient airflow, including air filtration systems, ventilation panels, and window or door screens. The structural integrity of steel wire mesh remains intact while ensuring minimal air resistance, guaranteeing the provision of effective airflow.

- Q: Can steel wire mesh be used for creating decorative wall panels?

- Yes, steel wire mesh can be used for creating decorative wall panels. Its strength and durability make it a suitable material for adding a modern and industrial aesthetic to any space. Additionally, the open pattern of the mesh allows for unique light and shadow effects, enhancing the overall decorative appeal of the panels.

- Q: What are the different types of coatings used for steel wire mesh?

- There are several types of coatings used for steel wire mesh, including galvanized, PVC coated, epoxy coated, and stainless steel coated. Each type of coating offers different benefits such as increased corrosion resistance, improved durability, and enhanced aesthetic appearance.

- Q: What are the load-bearing capabilities of steel wire mesh?

- The load-bearing capabilities of steel wire mesh depend on various factors such as the thickness of the wire, the size and spacing of the openings, and the overall design and installation of the mesh. However, in general, steel wire mesh is known for its high strength and durability, making it capable of supporting heavy loads. It is commonly used in construction, mining, and industrial applications where it can withstand significant forces and provide structural stability.

- Q: What are the different tensile strength options available for steel wire mesh?

- The tensile strength options available for steel wire mesh can vary depending on the specific needs and applications. Generally, steel wire mesh is produced with a wide range of tensile strengths to suit different requirements. Some common tensile strength options for steel wire mesh include: 1. Low Tensile Strength: This option is suitable for applications where the mesh is not expected to face significant stress or load. It offers basic strength and is typically used in lightweight applications such as fencing, screening, or decorative purposes. 2. Medium Tensile Strength: This option provides a higher level of strength compared to low tensile strength. It is commonly used in applications that require moderate load-bearing capabilities, such as in agricultural, construction, or industrial settings. 3. High Tensile Strength: This option offers superior strength and durability, making it ideal for applications that involve heavy-duty usage or require resistance to extreme forces. High tensile strength steel wire mesh is commonly employed in industries like mining, infrastructure, or automotive manufacturing. The specific tensile strength of steel wire mesh can vary based on factors such as the diameter of the wire used, the weaving pattern, and the quality of the steel. It is important to consult with manufacturers or suppliers to determine the most appropriate tensile strength option for a particular application.

Send your message to us

High Quality 304 Stainless Steel Wire Mesh

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords