Q41F-10C series lining fluorine ball valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Q41F-10C series lining fluorine ball valve descriptions

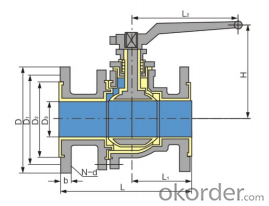

Q41F-10C series lining fluorine ball valve is a professional design for the opening and closing of all kinds of strong corrosive medium, the body USES the carbon steel precision casting, lined with fluorine plastic ball valve and flow components are using steel skeleton outsourcing fluorine plastic.

Widely used in petroleum, chemical, acid alkali, pesticides, dyes, waste-water treatment, electroplating, electronics and other industries.

2. Application environment

Applicable temperature-20℃~120℃

Nominal diameter:(DN)20-250mm

Nominal pressure:(PN)1.0MPa

3. Model sense

EX : Q41F-10-C-65

-Q: Type code:ballvalve

-4: Code for connection type: Flange

-1 : Code for connection type: Floating direct flow type

-F: Parts which is in contact with liquid flow is made with fluorine plastic

-10: Nominal Pressure 1.0MPa

-C: Material of valve body is carbon steel with melt mold

-65: Nominal Diameter is 65mm

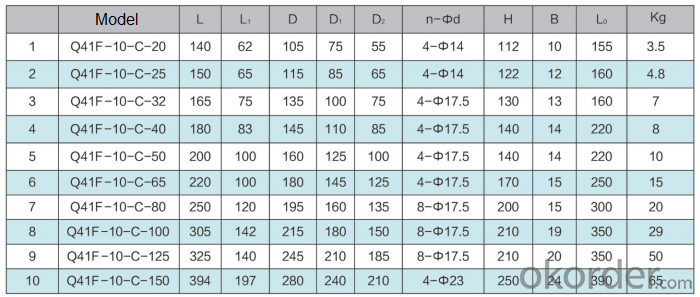

4. Model and parameter technical

5. Products features

-The fluorine lined ball valve with FEP lining layer has extremely high chemical stability and can be applied to any strong corrosion property except "molten alkali metal and element fluorine".

- Fluorine lined ball valve adopts the structure of full diameter and floating ball. The valve can be closed without leakage within the whole pressure range, which is more convenient for the ball cleaning and pipeline maintenance of the pipeline system.

- Ball parts and valve stem casting (forging) are integrated, eliminating the possibility of the valve stem bursting out of the pressure part due to pressure change, and fundamentally ensuring the safety in engineering.

- Fluorine lined ball valve structure is compact and reasonable, the body cavity space is the smallest, reduce the medium retention, in addition, special molding process, make the sealing surface density is good, combined with herringbone PTFE packing combination, make the valve to achieve zero leakage.

-Two-piece, three-piece structure can adapt to a variety of different requirements of the pipeline system and working conditions, including three-piece ball valve allows the main valve body and two sides of the body separation, ensure rapid online replacement, maintenance.

- Q: i was thinkin i needed rings cause my car was smokin like hell and had a bad compression test on one cylinder. anyways i got the head off and my valves are caked with black **** all down one side and the others are completely white. i dont know if when the car turns off if they're supposed to seal but four of them were about a quarter inch off the head. before i tested everything i was smokin like hell and barely runnin and you could hear a knockin sound in the exhaust at the rear of the car. could the head be the problem or still sound like rings??

- have the head checked for level milling it may be warped if it has ever overheated..

- Q: In the very near future I'm having valve replacement surgery. I haven't yet been told the risks or the recovery period, does anyone know the risks or the recovery stages and how long recovery takes?

- Valve replacements actually have very low morality rates like 1-2%. There are always risk's with surgery though, such as blood clots or irregular heart rate. The recovery in the hospital is generally 5-7 days, and then it can take anywhere from 8 weeks to a year to feel recovered.

- Q: I have a honda civic and i took it to get an oil change and they told me that i had an oil leak because my valve cover needed replacing. I did not let them do the work. I called my personal mechanic and he's out of commission for a little while, so he referred me to a friend of his. He said he cleaned all of the built up oil and replaced the valve cover. I noticed yesterday that my car looks like it is leaking oil really bad. I'm wondering, could this be from him washing the old oil that was leaking? My belts seem to be squeaking, like they do when it rains. Any ideas? could this just be excess water that he cleaned it out with?

- if he replaced the valve pan gasket then it could be from where it was leaking at in the first place and he did not clean it off after he got done. if your oil don,t keep going low then you know he got it fixed.

- Q: Is there a product that can fit over a foot valve to give it further protection in muddy water? I am looking for something for forest firefighting in mind. Something like a screen box something else that can give it further protection. It would be nice if it was small, and compact. Pictures would definitely be an asset. Thanks to everyone that answers. Greatly appreciated.

- most foot valves i have bought come with a strainer attached perhaps you should look for that type. if your valve has a strainer you may consider making a further coarse strainer out of a ball of chicken wire and place this over the foot valve assembly(thats what i do for the cold water supply to my house) don't compress the chicken wire very small as it will block up i tie the wire filter on with galvanized wire then i can easily replace it if necessary ps i tried stainless steel pot scourers but they were to fine and blocked easily

- Q: Does anyone know where i can get a chromed valve cover for a 99 eclipse or is there a way that i can do it myself? id like to get one that has the etched 2.0 and DOHC words on it

- You can have it dipped in chrome and detailed for the lettering. It pricey but its the best way or you could try finding chrome spray paint that is good up to 500 degrees and do it yourself but it may not look as good.

- Q: I have to get a new vacuum switching valve for my 1987 toyota pickup. I was just wondering what it does, and if a broken one would cause my truck to not idle. It still runs fine when i drive it, but when i push the clutch in the RPM's get really low until it dies.

- This valve probably is the EGR control valve - the computer monitors the EGR flow and controls the EGR valve opening by switching vacuum to it for opening or bleeding vacuum off for closing. If this valve fails to completely close the EGR valve at idle, the problem will mirror your symptoms

- Q: My third valve won't move at all. I haven't played my trumpet in a while and I tried to oil it to get it to unstick but it still won't move at all. People say to screw it off but I can only unscrew the little cap at the bottom of the valve where you push in, not the white button at the top. Help please! Thank you so much! =]

- on the top of the valve there is the screw that you turn to open the valve to oil it. if this screw wont turn gently tap the edges of it with the rim of your mouthpiece, and make sure that you get the entire screw cap. if this doesn't loosen it enough to remove the cap, then repeat while hitting it at an angle in the direction that it needs to turn. if this doesn't work take off the bottom cap and drip valve oil up though the bottom to drip up to the top cap and continue with the tapping process. if it still wont move, you need to take it to a shop. once the upper cap is loose, the valve still wont move, this is when you take off the bottom valve cap (if you haven't already) and fully remove a different valve that has already been oiled and push it up through the bottom of the stuck valve, this might be hard to do, and you might need to put in a lot of valve oil into the bottom to get it to move. once this valve is removed, thoroughly clean the valve casing and the valve itself, and oil both before replacing the valve. Hope this helps.

- Q: I bought a Bb trumpet from Ebay (I know, probably not the best idea) and when it arrived it was really good, except the valves. They wouldn't go down (or up) really well, so I oiled them, and it helped, but it still won't go up properly (it might go up halfway, then suddenly stop, then go up slowly). The valves sound like they're scraping the side a little, and valve oil doesn't do much good. I don't know what brand it is, so don't ask. Another thing, is there such a thing as over-oiling?

- When dealing with complex and artistic things such as musical instruments, ALWAYS buy form where you can trust, and preferably from where you can test the item out.

- Q: i heard i should get one rather than a Dump valve, well?, should i?

- It is often used as a safety devise in many industrial fields, first introduced on the early steam engines of the 19th century to prevent the boilers from blowing up due to excessive steam pressure. They still did often blow up as the early valves were quite primitive and often stuck closed,

- Q: I have mitral valve prolapse. Just recently Ive been getting chest pains more often * few times a day* and the panic and anxiety have gotten worse. I had a pain last night that lasted about 10 minutes and it was very uncomfortable.I know mitral valve prolapse is a condition that usually not a threat. But can it get worse over time with some people?My doctor already knows I have it but should I go back to have more tests done?Im kinda scared because my symptoms are getting to be more than what they were.Any advice?

- Mitral valve prolapse does not usually cause the painful symptoms usually associated with a heart attack. Depending on the severity it can cause dizziness or fainting on rising from a seated position. If you press on the left carotid artery, reducing blood flow to the brain a mitral valve prolapse condition will not be able to overcome the extra resistance applied to the artery and may cause a blackout. This depends on your exact condition. It can be corrected by surgery with either an artificial or an organic valve replacement. The chest pains may be something else going on with your heart or just caused by anxiety and stress. I believe it would be best if you went back to the cardiologist and had him/her check you out thoroughly. If only to set your mind at ease and relieve some of your anxiety. Take care

Send your message to us

Q41F-10C series lining fluorine ball valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords