GB Q235 Steel Angle with High Quality 45*45mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Q235 Steel Angle with High Quality 45*45mm:

1.Standards:GB

2.Length:6m, 12m

3.Material:Q235 or equivalent

4.Size:

Size (mm) | Mass (kg/m) | Size (mm) | Mass (kg/m) |

| 45*45*4 | 2.736 | 45*45*5 | 3.369 |

Usage & Applications of GB Q235 Steel Angle with High Quality 45*45mm:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of GB Q235 Steel Angle with High Quality 45*45mm:

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customers' request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

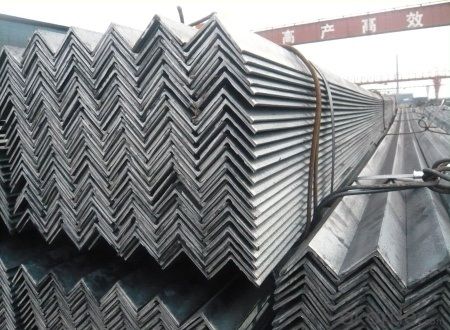

Images of GB Q235 Steel Angle with High Quality 45*45mm:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used in the construction of airport terminals?

- Airport terminals can indeed utilize steel angles in their construction. These angles are frequently employed in the field of construction due to their robustness, longevity, and adaptability. They are commonly incorporated into frameworks, supports, and bracing systems. In the construction of airport terminals specifically, steel angles can serve various purposes, including bolstering structural beams, framing windows and doors, constructing partitions, and fortifying walls and columns. Furthermore, steel angles can be easily joined together through welding, bolting, or fastening, allowing for efficient construction and flexibility in design. All in all, steel angles offer a dependable and cost-effective option for the construction of airport terminals.

- Q: Can steel angles be galvanized or coated for additional protection?

- Yes, steel angles can indeed be galvanized or coated for additional protection. Galvanizing is a common method used to protect steel from corrosion. It involves coating the steel with a layer of zinc, which acts as a barrier against moisture and other corrosive elements. This process can be done through hot-dip galvanizing, where the steel angle is immersed in a bath of molten zinc, or through electroplating, where a thin layer of zinc is applied to the surface of the steel through an electric current. Coating steel angles with other protective materials is also a viable option. There are various coating options available, such as epoxy, powder coatings, and paint. These coatings create a protective layer on the surface of the steel, shielding it from environmental factors that could lead to corrosion or damage. By galvanizing or coating steel angles, additional protection is provided, extending the lifespan of the material and ensuring its durability in different applications and environments.

- Q: How do steel angles perform in extreme temperatures?

- Steel angles are renowned for their exceptional performance in extreme temperatures. With their high melting point, they possess the ability to endure both exceedingly high and low temperatures without compromising their structural integrity. When faced with intense heat, steel angles display a remarkable resistance to thermal expansion, thereby preserving their form and strength. Similarly, even in extremely cold conditions, steel angles remain resilient and impervious to brittleness or weakness, ensuring their longevity and dependability. Consequently, steel angles are highly suitable for use in industries such as construction, automotive, and aerospace, where they are frequently subjected to a wide range of temperature variations. Furthermore, steel angles exhibit exceptional fire resistance, further augmenting their effectiveness in extreme temperature scenarios. All in all, when it comes to applications necessitating stability and strength in extreme temperatures, steel angles are the preferred choice.

- Q: How do steel angles differ from other structural shapes?

- Steel angles possess several distinguishing characteristics that set them apart from other structural shapes. Firstly, their cross-section takes on a distinct L-shape, featuring two perpendicular flanges and a central web connecting them. This exceptional shape grants the angle exceptional strength and load-bearing capacity, rendering it suitable for a myriad of structural applications. Secondly, steel angles exhibit remarkable versatility, finding utility in a wide array of construction projects. They can be effortlessly welded, bolted, or screwed together to forge intricate structures like frames, supports, and bracings. This adaptability endows them with a favored status among engineers and architects. Furthermore, steel angles come in various sizes and thicknesses, allowing for customization tailored to precise project requirements. This assortment in dimensions streamlines the attainment of desired strength and stability in structural designs. Moreover, steel angles provide cost-effective solutions in comparison to alternative structural shapes. Their resourceful utilization of materials and manufacturing processes renders them relatively affordable, all while maintaining their durability and functionality. Lastly, steel angles exhibit an impressive capacity to withstand substantial loads and stresses, making them an idyllic choice for applications where structural integrity is of paramount importance. Their ability to evenly distribute weight across the flanges and web ensures stability and prevents deformation under heavy loads. In conclusion, steel angles epitomize unique structural shapes, endowing construction projects with strength, versatility, customizability, cost-effectiveness, and durability. These attributes distinguish them from other structural shapes, rendering them an excellent choice for diverse construction endeavors.

- Q: Can steel angles be used as bracing elements?

- Yes, steel angles can be used as bracing elements. Steel angles are commonly used in construction and engineering projects for their strength and durability. They are often used to provide structural support and stability, including as bracing elements. Steel angles can be bolted or welded to other structural components to create a rigid and stable bracing system. Their L-shape design allows them to be easily attached to other members, providing additional strength and resistance against lateral forces such as wind or seismic loads. Overall, steel angles are a reliable choice for bracing elements in various applications, ranging from buildings and bridges to industrial structures.

- Q: How do you store and transport steel angles?

- Steel angles can be stored by stacking them horizontally on a flat and level surface, ensuring they are supported evenly to prevent deformation. To transport steel angles, they can be loaded onto flatbed trucks or trailers, securely strapped or chained to prevent movement during transit. Alternatively, they can be bundled together and lifted by cranes or forklifts, ensuring proper balancing and securing the bundle for safe transportation.

- Q: What is the minimum thickness for a steel angle bracket?

- The minimum thickness for a steel angle bracket can vary depending on the specific application and load requirements. However, in general, a minimum thickness of 1/8 inch (3.18 mm) is often considered standard for most angle brackets.

- Q: What are the different types of steel angles connections?

- There are several types of steel angle connections, including bolted connections, welded connections, and hybrid connections. Bolted connections use bolts and nuts to join the steel angles together, providing flexibility for disassembly and reassembly. Welded connections involve fusing the steel angles together using heat, creating a strong and permanent connection. Hybrid connections combine both bolted and welded connections, utilizing the benefits of each method for optimal strength and convenience.

- Q: Can steel angles be used in curtain wall systems?

- Certainly, curtain wall systems can incorporate steel angles. Typically, in such systems, steel angles function as support brackets or mullions. These angles offer structural stability and reinforcement for the glass panels or other types of cladding materials. It is possible to customize the sizes and shapes of steel angles to suit the specific design needs of the curtain wall system. Moreover, welding or bolting steel angles together allows for the creation of the desired framework for the curtain wall. In conclusion, steel angles present a robust and dependable choice for integration into curtain wall systems.

- Q: How are steel angles protected against abrasion?

- Steel angles can be protected against abrasion through various methods, such as applying anti-abrasion coatings, using rubber or plastic lining, or incorporating sacrificial wear plates. These protective measures help to minimize the wear and tear caused by friction and ensure the longevity and durability of the steel angles.

Send your message to us

GB Q235 Steel Angle with High Quality 45*45mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords