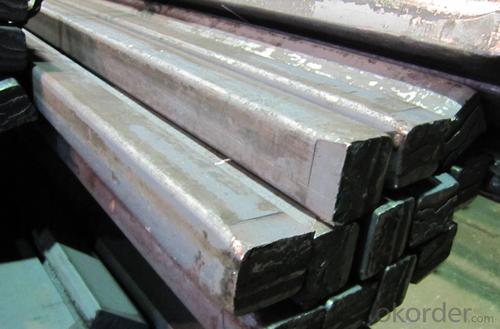

Q235/3SP 145MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 145MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 145MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 145MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 145MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 145MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different types of surface treatment methods used for steel billets?

- Steel billets can undergo various surface treatment methods to serve specific purposes. Here are some commonly employed techniques: 1. Pickling: By immersing steel billets in an acidic solution, typically hydrochloric or sulfuric acid, any scale or oxide layers on the surface can be eliminated. Pickling enhances the surface finish and readies the steel for further processing. 2. Shot Blasting: This method involves propelling high-velocity small metal or ceramic particles onto the steel billet surface. The process effectively removes rust, scale, and contaminants, resulting in a clean and smooth finish. 3. Grinding: To eradicate imperfections from the steel billet surface, mechanical abrasive wheels are utilized. Grinding can achieve a specific surface roughness, making it ideal for precision and accuracy requirements. 4. Acid Etching: By applying an acid solution to the steel billet surface, a controlled roughness or texture can be created. This enhances subsequent coating or paint adhesion. 5. Galvanizing: A layer of zinc is applied to the steel billets in this popular method. Zinc acts as a sacrificial barrier, providing excellent corrosion resistance and protecting the underlying steel from oxidation. 6. Powder Coating: Electrostatically applying a dry powder to the steel billet surface characterizes this technique. Upon heating, the powder melts and forms a protective layer known for its durability, corrosion resistance, and ability to offer diverse decorative finishes. 7. Passivation: This chemical process aims to enhance the corrosion resistance of stainless steel billets. It involves eliminating iron contaminants and forming a passive oxide layer that safeguards the steel from oxidation. These examples represent only a fraction of the surface treatment methods available for steel billets. The selection of a method depends on factors like desired surface finish, intended steel application, and required level of corrosion resistance.

- Q: How are steel billets used in the manufacturing of castings?

- Steel billets are an important raw material in the manufacturing of castings. Castings are solid metal objects that are formed by pouring molten metal into a mold and allowing it to cool and solidify. Steel billets are typically used as the starting material for this process. To create castings, steel billets are first heated to a high temperature until they become molten. This molten steel is then poured into a mold, which is typically made of sand or metal. The mold is designed to have the desired shape and dimensions of the final casting. Once the molten steel is poured into the mold, it is left to cool and solidify. As the steel cools, it takes on the shape of the mold, forming the desired casting. The cooling process is critical as it determines the strength, hardness, and other mechanical properties of the final product. After the steel has solidified, the mold is removed, and the casting is cleaned and finished. This may involve removing any excess material, such as gates or risers, that were used to facilitate the pouring of the molten metal. The casting may also undergo additional processes, such as machining or heat treatment, to achieve the desired final specifications. In summary, steel billets are used in the manufacturing of castings by being melted and poured into a mold to create the desired shape. The cooling and solidification of the molten steel within the mold results in the formation of a solid casting, which can then be further processed and finished as required.

- Q: Can steel billets be cold rolled?

- Steel billets cannot be cold rolled, as this process specifically involves reducing the thickness of a metal sheet or strip by passing it through a series of rollers at room temperature. Instead, steel billets are primarily utilized as raw material for producing steel bars, rods, and other long products through hot rolling. During hot rolling, the steel billets are heated to high temperatures and subsequently passed through rolling mills to achieve the desired shape and dimensions. Cold rolling is not appropriate for steel billets because it necessitates heating to enhance the steel's malleability and ability to deform, which cannot be achieved with solid, unheated billets.

- Q: How do steel billets contribute to energy efficiency?

- Steel billets have a significant impact on energy efficiency in various ways: 1. Enhanced production efficiency: Steel billets serve as the initial form of steel utilized in different manufacturing processes. Employing steel billets as the starting material allows manufacturers to achieve higher production efficiency. The uniform size and shape of billets facilitate easier handling, cutting, and shaping, thereby reducing energy consumption during manufacturing. 2. Optimized resource utilization: Steel billets are commonly produced from recycled steel scrap. By employing recycled steel as the raw material, manufacturers minimize the need for extracting and processing virgin iron ore, a highly energy-intensive procedure. This conservation of natural resources helps in reducing overall energy consumption related to steel production. 3. Efficient heat recovery: The manufacturing of steel billets necessitates high temperatures for melting and shaping the steel. However, modern steel plants are equipped with advanced technologies that enable efficient heat recovery. The excess heat generated during the process can be captured and utilized for various purposes, such as generating steam or heating other areas of the plant. This heat recovery system effectively reduces energy wastage and enhances overall energy efficiency. 4. Employment of energy-efficient equipment: Steel billet production often involves the use of heavy machinery and equipment. Manufacturers are increasingly investing in energy-efficient technologies and equipment to minimize energy consumption. For instance, the utilization of more efficient electric arc furnaces or induction heating systems can significantly reduce energy requirements compared to traditional methods. These technological advancements contribute to the overall energy efficiency of steel billet production. In conclusion, steel billets play a pivotal role in enhancing energy efficiency in the steel industry. Their impact is evident in production efficiency, resource optimization, heat recovery, and the utilization of energy-efficient equipment. By minimizing energy consumption, the use of steel billets promotes a more sustainable steel manufacturing process.

- Q: How do steel billets compare to other steel products?

- Steel billets are a type of semi-finished steel product that is widely used in various industries. When comparing steel billets to other steel products, there are several key factors to consider. Firstly, steel billets are considered to be more versatile compared to other steel products. This is because they can be easily transformed into various shapes and sizes through different manufacturing processes such as rolling, forging, and extrusion. This versatility makes steel billets suitable for a wide range of applications, including construction, automotive, and manufacturing industries. In terms of strength and durability, steel billets are known for their high tensile strength and excellent resistance to corrosion. This makes them suitable for use in demanding environments and applications where strength and durability are essential. Other steel products may have similar properties, but steel billets are often preferred due to their ability to be customized into specific shapes and sizes. Another important aspect to consider is the cost-effectiveness of steel billets. Compared to fully finished steel products, steel billets are more cost-effective as they require less processing and finishing. This leads to reduced production costs, which can be advantageous for industries seeking to minimize expenses while still maintaining high-quality steel. Additionally, steel billets are also more environmentally friendly compared to other steel products. Since they undergo less processing and finishing, the carbon footprint associated with their production is significantly lower. This aspect is particularly important for industries that prioritize sustainability and aim to reduce their impact on the environment. In conclusion, steel billets offer several advantages when compared to other steel products. Their versatility, high strength, cost-effectiveness, and environmental friendliness make them a preferred choice in various industries. The ability to customize their shape and size, coupled with their durability and resistance to corrosion, further enhances their appeal. Overall, steel billets are a reliable and efficient option for those seeking high-quality steel products.

- Q: What are the common challenges in steel billet production?

- There are several common challenges in steel billet production that manufacturers often face. One of the primary challenges is maintaining consistent quality throughout the production process. Steel billets need to meet specific standards and specifications in terms of chemical composition, mechanical properties, and surface finish. Any deviation from these requirements can lead to rejection of the billets, causing delays and additional costs. Therefore, ensuring consistent quality control throughout the production cycle is crucial. Another challenge is achieving the desired size and shape of the billets. Steel billets come in various sizes and shapes, depending on the intended use. Producing billets with accurate dimensions and shape requires precision and careful calibration of the equipment involved in the production process. Any deviation in size or shape can result in difficulties during downstream processes, such as rolling or forging, and may lead to product defects or inefficiencies. Maintaining efficient production rates is also a common challenge. Steel billet production often involves complex and time-consuming processes, such as melting, casting, and cooling. Any disruption or bottleneck in these processes can significantly impact the production rate and overall efficiency. It is crucial to optimize the production flow and identify and address any bottlenecks in order to meet demand and minimize production delays. Controlling energy consumption and minimizing waste is another challenge in steel billet production. The production of steel billets requires high energy inputs, such as electricity and fuel. Finding ways to reduce energy consumption and optimize the use of resources can help minimize production costs and environmental impact. Additionally, minimizing waste generation and implementing effective recycling or reusing strategies can further enhance the sustainability of the production process. Lastly, ensuring the safety of workers and maintaining a safe working environment is a critical challenge in steel billet production. The production process involves working with heavy machinery, high temperatures, and potentially hazardous materials. Implementing robust safety protocols, providing appropriate personal protective equipment, and conducting regular safety audits are essential to prevent accidents and ensure the well-being of the workforce. Overall, steel billet production faces challenges related to maintaining consistent quality, achieving accurate size and shape, maintaining efficient production rates, controlling energy consumption, and ensuring worker safety. Overcoming these challenges requires continuous improvement, investment in technology and equipment, and a commitment to quality control and safety measures.

- Q: How are steel billets used in the manufacturing of wire products?

- Steel billets are an essential component in the manufacturing of wire products. They serve as the starting material for the wire production process. Steel billets are semi-finished products that are typically cast in a rectangular or square shape. These billets are made from molten steel that is solidified and then subjected to various shaping processes to form the desired dimensions. The first step in using steel billets for wire production involves heating them in a furnace to a specific temperature. This heating process, known as annealing, helps soften the steel and make it more malleable. By doing so, it becomes easier to shape the billets into wire forms. Once the billets have been heated and softened, they are then passed through a series of rollers and drawing dies. These machines gradually reduce the cross-sectional area of the billets, elongating them into the desired wire diameter. The process of reducing the diameter of the billets is called wire drawing. During the wire drawing process, the steel billets undergo multiple passes through the rollers and drawing dies. Each pass reduces the diameter of the billets further until they reach the desired wire size. This continuous reduction in diameter also improves the mechanical properties of the wire, such as its tensile strength and ductility. After the wire drawing process, the steel wire is typically coiled onto spools or reels for further processing or distribution. Depending on the intended application, the wire may undergo additional treatments, such as heat treatment or surface coating, to enhance its properties or protect it from corrosion. In summary, steel billets are used in the manufacturing of wire products by being heated, shaped, and drawn through rollers and dies to reduce their diameter and transform them into wire forms. This process allows for the production of wires with various dimensions and properties, making them suitable for a wide range of applications in industries such as construction, automotive, electrical, and manufacturing.

- Q: What is the role of steel billets in the manufacturing of tools and dies?

- Steel billets are essential for the production of tools and dies, playing a crucial role in the manufacturing process. These semi-finished steel products serve as the starting material, being heated, forged, and shaped to create the desired tools and dies used in different industries. The use of steel billets offers several advantages, primarily due to their high strength and durability. Steel is known for its excellent mechanical properties, such as hardness, toughness, and wear resistance. When manufacturers use high-quality steel billets, they can be confident that the resulting tools and dies will have the necessary strength and durability to withstand demanding conditions. In addition, steel billets provide versatility in terms of customization. They can be easily shaped and formed into various sizes and dimensions, allowing manufacturers to create tools and dies that meet specific requirements. Whether it's a complex mold or a precision cutting tool, steel billets offer the flexibility needed to produce intricate and accurate components. Moreover, steel billets are preferred in the manufacturing of tools and dies due to their thermal conductivity. Steel effectively conducts heat, which is crucial for processes like heat treatment, quenching, and tempering. These thermal treatments are often used to enhance the hardness and strength of tools and dies, making them more resistant to wear and extending their lifespan. In conclusion, steel billets are indispensable in the manufacturing of tools and dies. They serve as the primary material for these components, providing high strength, durability, customization options, and thermal conductivity. By utilizing steel billets, manufacturers can create tools and dies that meet the demanding requirements of various industries, ensuring optimal performance and longevity.

- Q: How are steel billets tested for mechanical properties?

- Steel billets are tested for mechanical properties using various methods to ensure their quality and suitability for specific applications. One common method is the tensile test, which involves pulling a small sample from the billet and subjecting it to a gradually increasing tensile force until it fractures. This test helps determine important mechanical properties such as ultimate tensile strength, yield strength, and elongation. Another method used is the hardness test, which measures the resistance of the billet's surface to indentation. This test provides information about the billet's hardness, which is crucial for assessing its ability to withstand wear and deformation. Additionally, the impact test is performed to evaluate the billet's toughness and ability to absorb energy. This involves striking a standardized sample with a pendulum and measuring the energy absorbed during fracture. The impact test is particularly important for applications where the steel billet is subjected to sudden loads or impacts. To assess the billet's ability to resist deformation, the compression test is employed. In this test, the billet is subjected to a compressive force until it deforms or fractures. The results obtained from this test help determine the billet's compressive strength and deformation characteristics. Furthermore, non-destructive testing methods such as ultrasonic testing and magnetic particle inspection are used to detect any internal defects or irregularities in the billet. These methods involve the use of specialized equipment to examine the billet's internal structure and identify any flaws that may compromise its mechanical properties. Overall, steel billets undergo a comprehensive range of tests to ensure their mechanical properties meet the required standards. These tests help guarantee the quality and reliability of the billets, enabling them to be used in various industries such as construction, automotive, and manufacturing.

- Q: How are steel billets used in the manufacturing of oil and gas equipment?

- Steel billets are a crucial component in the manufacturing of oil and gas equipment. These billets, which are essentially semi-finished steel products, serve as the starting material for the fabrication of various equipment used in the oil and gas industry. One of the primary applications of steel billets is in the production of pipes. Oil and gas pipes need to withstand high pressure, extreme temperatures, and corrosive environments. Steel billets provide the raw material necessary to create seamless or welded pipes that can meet these demanding requirements. The billets are heated, pierced, and elongated through a process called extrusion, which enables the formation of seamless pipes. Alternatively, they can be rolled and welded to create longitudinally welded pipes. Steel billets are also used in the manufacturing of valves, fittings, and flanges. Valves play a critical role in controlling the flow of oil and gas within pipelines and equipment. Fittings, such as elbows, tees, and reducers, are used to connect pipes together or change their direction. Flanges, on the other hand, provide a means of connecting pipes, valves, and other equipment by bolting them together. All of these components require the use of steel billets as the starting material, which are then machined, shaped, and heat-treated to meet the necessary specifications and standards. Furthermore, steel billets are utilized in the fabrication of drilling equipment and offshore structures. Drilling equipment, including drill bits, drill collars, and drill pipes, are essential for oil and gas exploration and extraction. These components are subjected to intense forces and harsh conditions, making the use of high-quality steel billets crucial to ensure their strength and durability. Offshore structures, such as platforms and rigs, also require steel billets to construct the framework and support systems that can withstand the challenging marine environment. In summary, steel billets are indispensable in the manufacturing of oil and gas equipment. They serve as the raw material for pipes, valves, fittings, flanges, drilling equipment, and offshore structures. By starting with high-quality steel billets, manufacturers can produce durable and reliable equipment that can withstand the demanding conditions of the oil and gas industry.

Send your message to us

Q235/3SP 145MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords