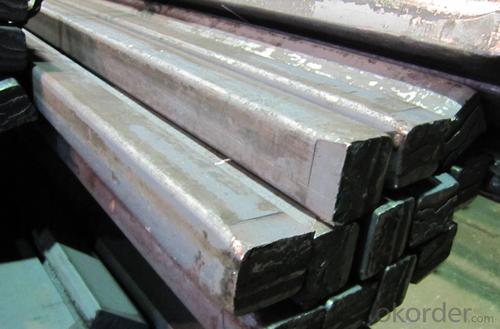

Q235/3SP 155MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 155MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 155MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 155MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 155MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 155MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets used in the manufacturing of heavy machinery?

- Steel billets are used in the manufacturing of heavy machinery as they serve as the raw material for forging, casting, and machining processes. These billets are heated, shaped, and transformed into various components such as gears, shafts, frames, and structural parts, which are essential building blocks for constructing heavy machinery. The high strength and durability of steel billets make them ideal for withstanding the heavy loads and harsh conditions that heavy machinery often operates in.

- Q: What are the main challenges in the transportation of steel billets?

- The main challenges in the transportation of steel billets include ensuring proper handling and securing of the heavy and bulky loads, preventing damage or deformation during loading and unloading processes, and complying with safety regulations for transporting hazardous materials. Additionally, factors such as limited availability of specialized equipment, fluctuations in fuel prices, and coordinating logistics for long-distance shipments can pose challenges for efficient and cost-effective transportation of steel billets.

- Q: How are steel billets used in the production of heat exchangers?

- Steel billets are an essential component in the production of heat exchangers. Heat exchangers are devices that transfer heat between two or more fluids, such as air and water, without them coming into direct contact. Steel billets, which are semi-finished metal products, serve as the raw material for manufacturing the various components of heat exchangers. Firstly, steel billets are used to create the tubes and pipes that form the primary framework of heat exchangers. These tubes are designed to withstand high pressures and temperatures while efficiently transferring heat. Steel, with its high strength and thermal conductivity, is an ideal material for this purpose. Next, the steel billets are processed through various techniques such as hot rolling, forging, or extrusion to shape them into the required dimensions. This process ensures that the tubes and pipes have the desired diameter, thickness, and length, which are crucial factors in determining the heat transfer efficiency of the heat exchanger. Additionally, steel billets are also used to produce the fins and plates of heat exchangers. Fins are thin, elongated structures that increase the surface area of the heat exchanger, allowing for enhanced heat transfer. Steel billets are shaped and cut into fins, which are then attached to the tubes or plates. These fins provide additional contact points for heat transfer and help improve the overall efficiency of the heat exchanger. Moreover, steel billets are used in the production of headers and manifolds, which are crucial components for the distribution and collection of fluids within the heat exchanger. These headers ensure that the fluids flow through the tubes and fins in a controlled manner, maximizing heat transfer and minimizing pressure losses. The strength and durability of steel make it a suitable material for these critical components. In conclusion, steel billets play a vital role in the production of heat exchangers. They are used to manufacture the tubes, pipes, fins, headers, and manifolds, which are all essential components of a heat exchanger. The use of steel ensures the durability, strength, and thermal conductivity required for efficient heat transfer in these devices.

- Q: What are the different surface treatments for improved surface roughness in steel billets?

- To enhance the surface roughness of steel billets, there are various surface treatments available. These treatments aim to improve the quality and properties of the billets, making them more suitable for different industrial applications. Some commonly used surface treatments for achieving better surface roughness in steel billets are as follows: 1. Shot Blasting: In shot blasting, high-speed abrasive particles are used to bombard the surface of the steel billets. This treatment effectively removes any contaminants, scale, or unevenness present on the surface, resulting in a smoother and more uniform finish. 2. Acid Pickling: Acid pickling involves immersing the steel billets in an acid solution, typically hydrochloric or sulfuric acid. This chemical treatment dissolves any oxides, rust, or scale present on the surface, leaving behind a clean and smoother surface. 3. Mechanical Grinding: Mechanical grinding employs abrasive wheels or belts to remove material from the surface of the steel billets. This treatment is particularly effective in eliminating deep scratches, pits, or irregularities, resulting in a smoother and more polished surface. 4. Electrochemical Polishing: Electrochemical polishing is an electrochemical process that combines chemicals and electrical current to remove a thin layer of material from the steel billet's surface. This treatment helps eliminate any surface imperfections, resulting in a smoother and more reflective finish. 5. Roller Leveling: Roller leveling involves passing the steel billets through a set of rollers that exert pressure on the surface, flattening and smoothing out any irregularities. This treatment is especially effective in improving the flatness and surface roughness of the billets. 6. Thermal Treatment: Thermal treatment, such as annealing, can also enhance the surface roughness of steel billets. Annealing involves heating the billets to a specific temperature and slowly cooling them to relieve internal stresses and improve the surface finish. It is crucial to consider the specific requirements of the steel billets and the desired surface roughness when selecting a surface treatment. Each treatment has its advantages and limitations, and factors such as the type of steel, dimensions of the billets, desired surface finish, and cost-effectiveness should be taken into account when choosing the most suitable treatment.

- Q: How are steel billets handled during transportation?

- Steel billets are typically handled with great care during transportation to ensure their safety and prevent any damage. They are usually transported using specialized equipment such as cranes, forklifts, or conveyors. These tools are used to lift and move the heavy billets from one location to another. Before transportation, the billets are often bundled or secured together to prevent them from shifting or falling during transit. This bundling process can involve using steel straps or bands to hold the billets tightly together, ensuring they remain stable and intact during transportation. In addition to securing the billets, protective measures are often taken to prevent any external damage. For instance, the billets may be covered with protective coatings, such as oil or rust inhibitors, to shield them from moisture or corrosion. This is particularly important when transporting billets over long distances or in adverse weather conditions. During transportation, the billets are carefully loaded onto trucks, trains, or ships, depending on the destination. Special attention is given to balancing the weight distribution to prevent any imbalance or tipping during transit. The transportation vehicles used are designed to handle heavy loads and often have mechanisms in place to secure the billets further, such as straps, latches, or containers. While in transit, the vehicles carrying the steel billets are driven or operated with caution to minimize any sudden movements or impacts. Drivers may need to follow specific routes or speed limits to ensure a smooth and safe journey. Regular inspections and maintenance of the transportation vehicles are conducted to ensure their reliability and prevent any mechanical failures that could jeopardize the safety of the billets. Overall, the transportation of steel billets involves a combination of careful planning, secure bundling, protective measures, and safe handling techniques. These practices aim to safeguard the billets and ensure they reach their destination in optimal condition, ready for further processing or use in various industries.

- Q: What are the different surface defects in steel billets?

- Some common surface defects in steel billets include cracks, scars, pits, surface roughness, and scale.

- Q: What is the typical size and shape of steel billets?

- Steel billets commonly have a rectangular or square form and are available in different dimensions. The prevailing measurements usually vary from 100mm x 100mm to 300mm x 300mm, while the lengths typically span from 3 meters to 12 meters. Nevertheless, the size and configuration of steel billets are subject to change based on the particular demands of the steel manufacturing process and the intended purpose of the billets.

- Q: How are steel billets used in the production of oil and gas equipment?

- Steel billets are an essential component in the production of oil and gas equipment. These billets are semi-finished steel products that are typically square or rectangular in shape, and they serve as the primary raw material for manufacturing various oil and gas equipment. Firstly, steel billets are used in the production of pipes, which are crucial for transporting oil and gas from the extraction sites to refineries or distribution points. Billets are heated and then rolled into seamless or welded pipes, depending on the specific requirements. These pipes are designed to withstand high pressure, corrosive environments, and extreme temperatures, making them suitable for transporting oil and gas through pipelines over long distances. Additionally, steel billets are used in the manufacturing of valves and fittings, which are integral components of oil and gas equipment. Valves control the flow of oil and gas within pipelines, allowing for regulation and shut-off when necessary. Fittings, such as connectors and couplings, ensure the proper connection and alignment of different pipe sections. These components are typically forged or machined from steel billets to ensure strength, durability, and resistance to harsh operating conditions. Furthermore, steel billets are utilized in the production of drilling equipment, such as drill bits, drill collars, and drill pipes. These components are subjected to extreme forces and abrasive environments during the drilling process. Steel billets are forged, heat-treated, and machined to create these drilling tools, ensuring they can withstand the demanding conditions encountered during oil and gas exploration. In summary, steel billets play a crucial role in the production of oil and gas equipment. They are used to manufacture pipes, valves, fittings, and drilling equipment, which are essential for the extraction, transportation, and processing of oil and gas. The high strength, durability, and resistance to harsh conditions make steel billets an ideal raw material for constructing reliable and efficient equipment in the oil and gas industry.

- Q: What are the different surface treatments for improved corrosion resistance in steel billets?

- Steel billets can undergo different surface treatments to enhance their resistance to corrosion. These treatments aim to establish a protective barrier on the steel's surface, preventing corrosive agents from reaching the metal beneath. Some commonly used surface treatments for improved corrosion resistance in steel billets include: 1. Hot-dip galvanizing: Immersing the steel billets in molten zinc creates a galvanized coating, which is a zinc-iron alloy. This coating offers excellent corrosion resistance and prolongs the lifespan of the steel billets. 2. Electroplating: Through electroplating, a thin layer of metal such as zinc or nickel is applied to the steel billets using an electric current. This layer acts as a protective barrier against corrosion and provides an attractive finish. 3. Powder coating: By applying a dry powder mixture of resin and pigment to the steel billets and heating it, a durable and corrosion-resistant layer is formed. Powder coating is available in various colors and finishes. 4. Paint coatings: Applying corrosion-resistant paint to steel billets creates a protective barrier that hinders moisture and corrosive agents from reaching the steel. Multiple layers of paint can be added for enhanced durability and longevity. 5. Passivation: Passivation is a chemical process that eliminates free iron and contaminants from the steel billets' surface. This process prevents corrosion and encourages the formation of a protective oxide layer. Passivation is often combined with other surface treatments like electroplating or powder coating to enhance corrosion resistance. It is important to consider factors such as the billets' operating environment, desired lifespan, and cost considerations when choosing a surface treatment for improved corrosion resistance. A thorough evaluation of specific requirements and professional consultation are crucial in determining the most suitable treatment option.

- Q: How do steel billets contribute to the manufacturing of telecommunications equipment?

- Steel billets play a crucial role in the manufacturing of telecommunications equipment by providing the necessary raw material for various components and structures. These billets, typically made from carbon steel, are semi-finished products that are further processed to create specific shapes and sizes required for telecommunications equipment. One of the key ways steel billets contribute to the manufacturing of telecommunications equipment is by serving as the base material for the fabrication of towers and masts. These structures are vital for the installation of antennas and satellite dishes, enabling the transmission and reception of signals for telecommunications networks. Steel billets are shaped and welded to create sturdy and durable towers that can withstand various environmental conditions. Moreover, steel billets are also used in the production of enclosures and cabinets for housing telecommunication equipment. These enclosures provide protection from external factors such as dust, moisture, and vandalism, ensuring the proper functioning and longevity of the equipment. Steel billets are formed into panels, frames, and chassis that are then assembled to create robust enclosures that can withstand harsh environments. In addition, steel billets contribute to the manufacturing of telecommunications equipment by being used in the production of cable trays and supports. These components are essential for organizing and routing cables, providing a neat and efficient infrastructure for telecommunications systems. Steel billets are rolled and formed into various shapes, such as channels and angles, to create sturdy cable trays and supports that can handle the weight and stress of multiple cables. Furthermore, steel billets are also utilized in the fabrication of connectors and brackets for telecommunications equipment. These small yet crucial components provide the necessary connections and support for different devices and modules in telecommunications systems. Steel billets are machined, drilled, and shaped into specific designs to create reliable connectors and brackets that ensure proper functionality and stability. Overall, steel billets play a vital role in the manufacturing of telecommunications equipment by providing the necessary raw material for various components and structures. Their strength, durability, and versatility make them an ideal choice for creating robust and reliable equipment that can withstand the demands of modern communication networks.

Send your message to us

Q235/3SP 155MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords