Q195, Q235, Q275, JIS Ss400, 3sp, 4sp Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

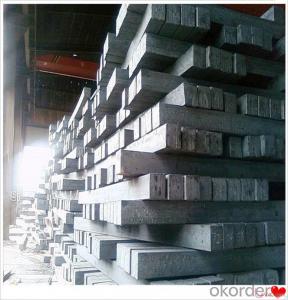

Gbq195, Q235, Q275, JIS Ss400, 3sp, 4sp Steel Billets

1.Executive Standard:GB,ASTM,DIN,JIS,BS

2.Product:Q195,Q235,Q275,SS400,S185,S235JR Steel Billets

3.Process: Hot rolled

4.Application:These products are widely used in all kinds of architecture and engineering structure, such as the beam, Bridges, transmission tower, hoisting, ship,industrial furnace, container frame and warehouse and Other fields.

5.Surface Condition: Black or as required

6.MOQ:1000MT

7.Chemical Composition:

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

1. Q: Where is your company located? How can I visit there?

A: Our company is located in Beijing, China. Welcome to visit us.

2. Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

3. Q: What's the MOQ?

A: Our MOQ is 1000mt.

4. Q: What's the delivery time?

A: It will take about 30-45 days after TT or L/C.

5. Q: What is the payment terms?

A: T/T, L/C at sight

6. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

7. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: How are steel coils used in the production of steel fasteners?

- Steel coils are used in the production of steel fasteners by being processed into flat strips or wires, which are then cut, shaped, and threaded to create various types of fasteners such as screws, bolts, and nuts. The coils provide a continuous supply of steel material that is easily manipulable and can be efficiently transformed into the desired shape and size for fastener production.

- Q: so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- It rather relies upon on what type of music you're enjoying, nylon string guitars have a mellow, softer tone than steel strings, the feel of the nylon strings (a minimum of to me) are reliable, in my opinion, i might ought to declare nylon is extra suitable, large for finger choosing and a effective tone. once you're searching for a guitar, you are able to flow out to a close-by guitar save, and attempt the two out for your self, in straight forward terms then will you comprehend for specific.

- Q: What are the common applications of pre-painted steel coils?

- Pre-painted steel coils, also known as pre-coated steel coils or color coated steel coils, are widely used in various industries due to their versatility and durability. Some of the common applications of pre-painted steel coils include: 1. Construction: Pre-painted steel coils are extensively used in the construction industry for roofing, wall cladding, and building panels. The color options available in pre-painted steel coils allow architects and designers to create aesthetically pleasing structures. 2. Automotive: Pre-painted steel coils are used in the automotive industry for manufacturing car bodies, interior panels, and various other parts. The corrosion resistance and excellent finish provided by pre-painted steel coils make them a preferred choice in this industry. 3. Appliances: Many household appliances like refrigerators, washing machines, and air conditioners use pre-painted steel coils for their outer panels. The attractive colors and textures available in pre-painted steel coils help enhance the appearance of these appliances. 4. Electronics: Pre-painted steel coils are also used in the electronics industry for manufacturing cabinets and casings of electronic devices like computers, televisions, and audio systems. The protective coating on pre-painted steel coils helps protect the electronic components from environmental factors. 5. Furniture: Pre-painted steel coils find applications in the furniture industry for manufacturing cabinets, shelves, and other similar products. The wide range of colors and finishes available in pre-painted steel coils allows furniture manufacturers to create visually appealing and durable products. 6. Signage and Advertising: Pre-painted steel coils are commonly used in signage and advertising applications for manufacturing display boards, billboards, and signages. The vibrant colors and weather-resistant properties of pre-painted steel coils make them suitable for outdoor use. 7. Industrial Equipment: Pre-painted steel coils are utilized in the manufacturing of industrial equipment such as storage tanks, HVAC systems, and machinery components. The corrosion resistance and high strength of pre-painted steel coils make them suitable for these demanding applications. In summary, pre-painted steel coils have a wide range of applications in various industries such as construction, automotive, appliances, electronics, furniture, signage, and industrial equipment. Their durability, corrosion resistance, and aesthetic appeal make them a popular choice for manufacturers across different sectors.

- Q: how is stainless steel made? what are the things used in making it?

- There are 3 basic stainless steels. The Martinsitic, the ferritic, and the Austinistic. The spelling may be wrong on all of them. (Got out of school in 1966 with my metallurgy in 1965. The Ferritic is magnetic and has some resistance to corrosion but the Martinsitic is much more resistant to corrosion. The Austinitic stainless is very resistant to corrosion. The differences are the amount of Chrome and Nickel in the batches. The Austinitic has an 18/8 ratio of Chromium and Nickel with the rest Iron and minor ingredients. The carbon content is very important and these steels are often made in small batches with close monitoring of composition and carbon content. Scrap metals are frequently used with the chrome and nickel being added as carefully selected scrap or even fresh crude stocks. Electric melting is frequent to avoid contamination.

- Q: What are the different types of steel coil recoiling methods?

- There are three main types of steel coil recoiling methods: slit edge recoiling, mill edge recoiling, and oscillated recoiling.

- Q: I bought a Remington 870 super mag last fall and wanted to to switch to non-tox steel loads. The gun came with a modified rem choke. I know that not all chokes are qualified to handle steel. It doesn't say anywhere on the choke no steel I was just wondering if anyone out there knew for sure that those chokes that the guns come with won't get damaged be steel.

- Remington 870 Chokes

- Q: How are steel coils used in the production of power generation equipment?

- Steel coils are used in the production of power generation equipment as they are shaped and formed into various components such as turbine casings, generator frames, and steam pipes. These coils provide the necessary strength and durability to withstand the high temperatures, pressure, and mechanical stresses involved in power generation processes. Additionally, steel coils are often coated with protective layers to prevent corrosion, ensuring the longevity and reliability of the equipment.

- Q: and what are the four main elements in STAINLESS steel? x

- Very high carbon steel (0.96 to 2.11%) is hard and not very ductile (difficult to mold or shape). It is also difficult to weld, but has the lowest melting point. As the carbon content is reduced, the steel becomes softer, more ductile and melts at a higher temperature. Stainless steel is an alloy of Iron, Carbon, Chromium. The fourth element would depend upon the grade of steel, but Nickel is probably the most common.

- Q: How are steel coils used in the production of HVAC equipment?

- Steel coils are used in the production of HVAC equipment as they serve as the primary components for heat transfer. These coils are responsible for facilitating the transfer of heat between the air and refrigerant, ensuring efficient cooling or heating of the air circulating within the HVAC system.

- Q: How do steel coils compare to other materials?

- Steel coils have several advantages over other materials. Firstly, steel is known for its high strength and durability. This makes steel coils highly resistant to wear and tear, making them suitable for a wide range of applications. Additionally, steel coils have excellent heat resistance, making them ideal for use in high-temperature environments. Furthermore, steel coils have superior corrosion resistance compared to many other materials. This is especially important in industries such as construction and automotive, where exposure to moisture and chemicals is common. Steel coils can withstand these harsh conditions, ensuring long-lasting performance and reliability. Another advantage of steel coils is their versatility. Steel can be easily molded into various shapes and sizes, allowing for customization and flexibility in design. This makes steel coils suitable for a wide range of applications, including manufacturing, construction, transportation, and energy industries. Moreover, steel coils offer good value for money. Despite their numerous benefits, steel coils are generally more affordable compared to other materials such as aluminum or copper. This makes steel coils a cost-effective choice for businesses and industries looking for high-quality and reliable materials. In summary, steel coils have several advantages over other materials. They offer high strength, durability, and heat resistance, along with superior corrosion resistance. Steel coils are also versatile and can be easily customized to suit different applications. Additionally, they provide good value for money. Overall, steel coils are a reliable and efficient choice for various industries and applications.

Send your message to us

Q195, Q235, Q275, JIS Ss400, 3sp, 4sp Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords