Q195, Q235, 3sp, 4sp, SS400 Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Description

Basic Info.

Model NO.: Q195/215/235/345/45#/ASTM A36, JIS SS400

Standard: AISI, JIS, ASTM, DIN, BS, GB

Technique: Hot Rolled

Process: Hot Rolled

Grade: Q195/215/235/345/45#/ASTM A36, JIS Ss400

Dimensions: 20*20-150*150mm

Length: 6-12m or as Required

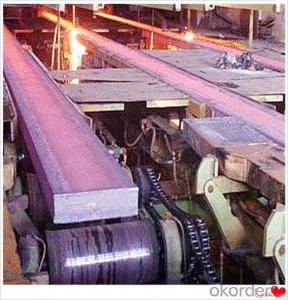

2. Product Picture

3. Packaging and Shipment

Packaging: In Bundle

Export Markets: Global

Application: Carbon structural steel, alloy structural steel, gear steel, spring steel,

Bearing steel, etc.

Packaging Detail: Exporting standard packing in mill or as request

Delivery Detail: Within 15-30 days after receiving deposits or original LC

The Billets produced by the company can be broadly divided into three main types i. E.

1. M. S. Billets

2. CRS Billets

3. Special Alloy Billets

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

4. Production Process

- Q: How is steel wire rope inspected for fatigue and wear?

- Steel wire rope is inspected for fatigue and wear through visual examination and non-destructive tests. This includes inspecting the rope for signs of corrosion, broken wires, or distorted strands. Additionally, magnetic particle inspection and ultrasonic testing are often used to detect hidden defects and measure the rope's internal condition. Regular inspections and maintenance help ensure the integrity and safety of steel wire ropes.

- Q: What are the applications of steel in the chemical industry?

- Steel has numerous applications in the chemical industry due to its exceptional properties. It is commonly used for constructing chemical storage tanks, pipelines, and equipment due to its high strength, durability, and resistance to corrosion. Steel is also utilized in the production of catalysts, reactors, and heat exchangers, where it can withstand high temperatures and pressure. Additionally, steel is an essential material for constructing industrial buildings, support structures, and platforms that house chemical manufacturing facilities.

- Q: What are the different types of steel roofing materials?

- There are several types of steel roofing materials available, including galvanized steel, galvalume steel, zincalume steel, and stainless steel. Each type offers different properties and advantages, such as corrosion resistance, durability, and aesthetic appeal.

- Q: What are the uses of steel in the oil and gas industry?

- Steel is widely used in the oil and gas industry for various applications due to its strength, durability, and resistance to corrosion. It is commonly used in the construction of oil rigs, pipelines, and storage tanks. Steel is also used in the manufacturing of valves, fittings, and other equipment necessary for the extraction, refining, and transportation of oil and gas. Its exceptional properties make steel a reliable and essential material in ensuring the safety and efficiency of operations in the oil and gas industry.

- Q: How do steel products contribute to the transportation industry?

- Steel products play a crucial role in the transportation industry by providing strength, durability, and safety to various components and structures. Steel is extensively used in the manufacturing of vehicles, such as cars, trucks, trains, ships, and airplanes, due to its high tensile strength and ability to withstand extreme conditions. It is used in the construction of frames, chassis, body panels, and engine components, ensuring the structural integrity and longevity of these vehicles. Additionally, steel is utilized in infrastructure projects like bridges, tunnels, and railway tracks, enhancing the reliability and safety of transportation systems. Overall, steel products are vital for the transportation industry as they contribute to the efficiency, performance, and safety of various modes of transportation.

- Q: What are the different methods of testing the quality of steel products?

- There are several methods of testing the quality of steel products, including destructive and non-destructive testing methods. Destructive testing involves subjecting the steel to extreme conditions, such as tension, compression, or bending, to determine its mechanical properties and strength. Non-destructive testing methods include visual inspection, ultrasonic testing, magnetic particle testing, and radiographic testing, which allow for the detection of defects or irregularities in the steel without causing any damage. These testing methods help ensure that steel products meet the required quality standards and are fit for their intended applications.

- Q: What are the uses of steel in the manufacturing of household appliances?

- Steel is commonly used in the manufacturing of household appliances due to its durability, strength, and resistance to corrosion. It provides a sturdy framework for appliances such as refrigerators, ovens, and washing machines, ensuring their longevity and reliability. Additionally, steel's malleability allows for intricate designs and shapes, enabling manufacturers to create aesthetically pleasing appliances. Its ability to conduct heat efficiently also makes it suitable for applications such as cookware and heating elements.

- Q: What is the role of steel in the energy sector?

- Steel plays a crucial role in the energy sector as it is used in the construction of power plants, transmission towers, and pipelines. It provides strength and durability to these structures, ensuring their safety and longevity. Additionally, steel is utilized in the manufacturing of wind turbines, solar panels, and energy storage systems, enabling the production and distribution of renewable energy. Overall, steel is an essential material that supports the infrastructure and development of the energy sector.

- Q: What are the applications of steel forgings in the aerospace industry?

- Steel forgings are widely used in the aerospace industry due to their exceptional strength, durability, and resistance to extreme conditions. They are commonly employed in critical components such as turbine disks, landing gear, wing fittings, and engine shafts. The superior mechanical properties of steel forgings ensure optimal performance, reliability, and safety in aircraft, making them vital for the aerospace sector.

- Q: How are steel profiles used in the fabrication of conveyor systems?

- Steel profiles are used in the fabrication of conveyor systems as they provide the necessary structure, strength, and durability required to support and transport materials. These profiles are used to create the frame and framework of the conveyor, as well as various components such as supports, rollers, and guides. The steel profiles are designed and configured to meet specific load capacities and operational requirements, ensuring reliable and efficient movement of goods in industrial and commercial settings.

Send your message to us

Q195, Q235, 3sp, 4sp, SS400 Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords