Q195, Q235, Q345B, SS400, A36, S235JR, S355JR, SAE1020, SAE1045, 3SP, 5SP Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

steel billets

Size:30*30mm-150*150mm

Standard: GB,BS,ASTM

Grade: Q195, Q235, Q345B, SS400, A36, S235JR, S355JR, SAE1020, SAE1045, 3SP, 5SP

Application: Carbon structural steel, alloy structural steel, gear steel, spring steel,

bearing steel, etc.

Packaging Detail: exporting standard packing in mill or as request

Delivery Detail: within 15-30 days after receiving deposits or original LC

The Billets produced by the company can be broadly divided into three main types i.e.

1. M.S. Billets

2. CRS Billets

3. Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and

various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like

Earthquake resistant TMT Re-Bars and for special grade structural steel products.

steel billets

| Ladle Analysis: | ||

| Designation | Carbon | Manganese |

| C15 | 0.12-0.18 | 0.30-0.60 |

| C18 | 0.15-0.21 | 0.30-0.60 |

| C20 | 0.17-0.23 | 0.30-0.60 |

| C15 MMn | 0.12-0.18 | 0.60-1.00 |

| C18 MMn | 0.15-0.21 | 0.60-1.00 |

| C20 MMn | 0.17-0.23 | 0.60-1.00 |

| C15 HMn | 0.12-0.18 | 1.00-1.50 |

| C18 HMn | 0.15-0.21 | 1.00-1.50 |

| C20 HMn | 0.17-0.23 | 1.00-1.50 |

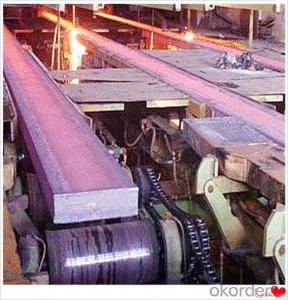

steel billets display

Pre-sale Service

1. Sample can be offered free fast while courier fee paid by buyer's side.

2. We have full stock, and can deliver within short time. Many styles for you to choose.

3. OEM and ODM order are accepted, any kind of logo printing or design are available.

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5. All of our products are produced by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

6. We have rich experience of design, manufacture and sell solar water heater, we cherish every order from our honor.

After you choose

1. We will count cheapest shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment,

3. Email you the tracking no, and help to chase the parcels until it arrive you.

After-sale service

1. We are very glad that customer give us some suggestion for price and products.

2. If any question, please contact with us freely by E-mail or Telephone.

- Q: How are steel products used in the railway industry?

- Steel products are used extensively in the railway industry for various purposes such as constructing tracks, bridges, and tunnels, manufacturing train components like locomotives and rolling stock, and providing structural support to the infrastructure.

- Q: How are steel products used in the manufacturing of household appliances?

- Steel products are used in the manufacturing of household appliances due to their durability, strength, and heat resistance. Steel is commonly used for the frames, bodies, and internal components of appliances like refrigerators, ovens, and dishwashers. It provides stability and support, ensuring the longevity of the appliances. Additionally, steel's resistance to corrosion and high temperatures makes it suitable for various parts that come into direct contact with heat or water, such as heating elements, stove burners, and tubs in washing machines.

- Q: How is steel used in the production of elevator systems?

- Steel is a crucial material in the production of elevator systems as it is used for constructing the elevator car, the support structure, and the guide rails, ensuring durability, strength, and safety for the entire system.

- Q: What are the common uses of steel in the defense industry?

- Steel is commonly used in the defense industry for a variety of applications such as manufacturing armored vehicles, naval ships, aircraft carriers, submarines, and tanks. It is also utilized for constructing military infrastructure, including bunkers, fortifications, and military base facilities. Furthermore, steel is essential for producing weapons, ammunition, and equipment for the armed forces. Its high strength, durability, and resistance to impact make it an ideal material for ensuring the safety and effectiveness of defense operations.

- Q: What are the common types of steel products used in the pet food and supplies industry?

- The common types of steel products used in the pet food and supplies industry include stainless steel bowls and dishes, steel cages and crates, steel shelving and storage units, and steel pet grooming tables and equipment.

- Q: What are the environmental impacts of steel production and the use of steel products?

- The environmental impacts of steel production and the use of steel products are significant. Steel production is a highly energy-intensive process that contributes to greenhouse gas emissions, primarily in the form of carbon dioxide. The extraction of raw materials, such as iron ore and coal, for steel production also leads to habitat destruction and deforestation. Additionally, steel production produces air pollutants including sulfur dioxide, nitrogen oxides, and particulate matter, which contribute to air pollution and respiratory problems. The process also generates large amounts of waste, such as slag and dust, which can contaminate soil and water sources if not properly managed. The use of steel products also has environmental implications. The manufacturing, transportation, and disposal of steel products contribute to carbon emissions and energy consumption. Furthermore, when steel products reach the end of their life cycle, improper disposal can result in waste accumulation in landfills. However, it is important to note that steel is a highly recyclable material, and recycling can significantly reduce the environmental impacts associated with its production. By promoting sustainable practices, such as using recycled steel and improving energy efficiency in production processes, we can mitigate the environmental impacts of steel production and use.

- Q: How is steel used in the manufacturing of storage tanks?

- Steel is commonly used in the manufacturing of storage tanks due to its durability, strength, and resistance to corrosion. It provides a reliable and long-lasting material for containing and storing various substances such as liquids, gases, or solids. Steel storage tanks are widely used in industries such as oil and gas, chemical, water treatment, and agriculture, ensuring the safe and efficient storage of materials.

- Q: What is the role of steel in the telecommunications industry?

- Steel plays a crucial role in the telecommunications industry as it is used to construct communication towers and support structures. These structures provide the necessary height and stability for antennas and satellite dishes, allowing for the transmission and reception of signals. Steel's strength, durability, and cost-effectiveness make it an ideal material choice for these applications, ensuring reliable and efficient communication networks.

- Q: What are the different methods of shaping steel into desired forms?

- There are several methods of shaping steel into desired forms, including forging, casting, rolling, and extrusion.

- Q: What are the applications of steel mesh in security fencing?

- Steel mesh is commonly used in security fencing applications due to its high strength and durability. It provides a secure barrier that prevents unauthorized entry and acts as a deterrent to potential intruders. Steel mesh also allows for visibility, making it suitable for areas that require constant monitoring. Additionally, its versatility and customizable design make it ideal for various security applications such as protecting commercial properties, residential areas, prisons, airports, and construction sites.

Send your message to us

Q195, Q235, Q345B, SS400, A36, S235JR, S355JR, SAE1020, SAE1045, 3SP, 5SP Steel Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords