OEM Painted Aluminum Sheets 4x8 - Python Embossed Sheet for Automotive Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Python Embossed Sheet for Automotive Tool Box

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Python Embossed Sheet for Automotive Tool Box

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Python Embossed Sheet for Automotive Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

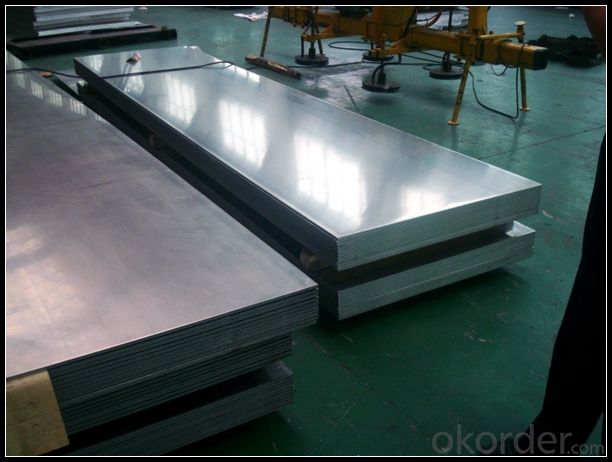

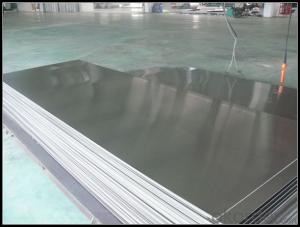

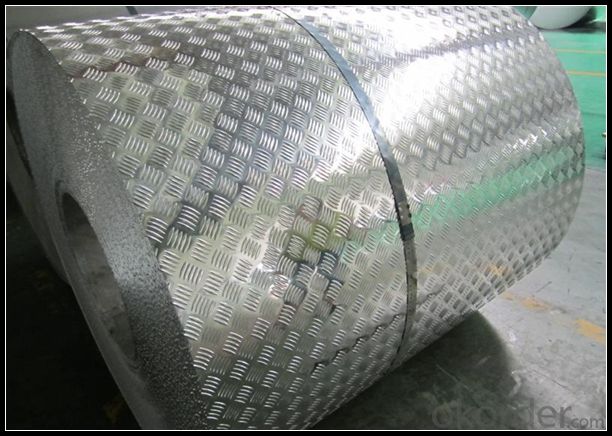

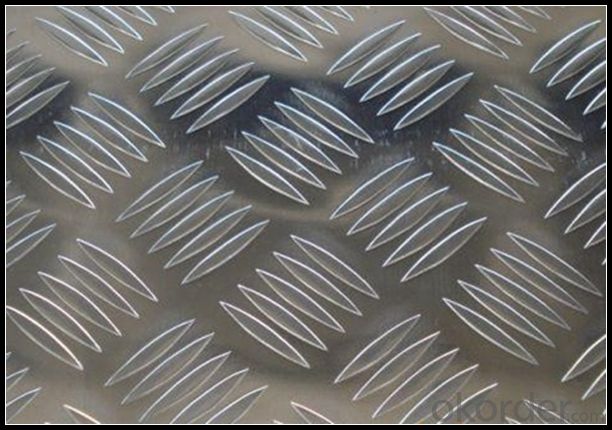

5. Image of Python Embossed Sheet for Automotive Tool Box

6. Package and shipping of Python Embossed Sheet for Automotive Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for methods to prevent rusting on aluminum sheets during the installation process.

- <p>To prevent rusting on aluminum sheets during installation, ensure that the aluminum is of high quality and free from impurities. Keep the surface clean and dry at all times, avoiding contact with corrosive materials. Use appropriate protective coatings or sealants that are compatible with aluminum. Avoid scratches or dents that can expose the metal to moisture. Store aluminum sheets in a dry place before installation. During installation, handle the sheets carefully to avoid damage. Regularly inspect and maintain the aluminum sheets to catch any signs of corrosion early.</p>

- Q: What types of aluminum sheets are recommended for outdoor applications?

- <p>Yes, there are specific types of aluminum sheets suitable for exterior use. These include aluminum sheets with a protective coating, such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a Kynar 500庐 PVDF coating are highly resistant to UV rays, making them ideal for exterior applications. Marine-grade aluminum is also recommended for exterior use due to its superior corrosion resistance, especially in coastal areas. These types of aluminum sheets are designed to withstand harsh outdoor conditions and maintain their integrity over time.</p>

- Q: How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, several preventive measures can be taken: 1. Barrier Coating: Apply a barrier coating or paint on the aluminum sheets to separate them from the concrete. This coating acts as a protective layer, preventing direct contact between the aluminum and the concrete, thereby reducing the chances of galvanic corrosion. 2. Insulation: Introduce an insulating material between the aluminum sheets and the concrete. This material can be a non-conductive plastic or rubber sheet that effectively isolates the aluminum from the concrete, minimizing the risk of galvanic corrosion. 3. Surface Treatment: Apply a corrosion-resistant treatment to the aluminum sheets. Anodizing is a common surface treatment method that creates a protective oxide layer on the aluminum surface, making it more resistant to corrosion when in contact with concrete. 4. Use Dissimilar Metals: Avoid using dissimilar metals in contact with aluminum sheets and concrete. When dissimilar metals, such as steel or iron, come into contact with aluminum in the presence of moisture, galvanic corrosion is more likely to occur. Therefore, it is best to use aluminum fasteners or supports when working with aluminum sheets and concrete. 5. Proper Drainage: Ensure proper drainage in areas where aluminum sheets are in contact with concrete. Accumulation of water or moisture can accelerate galvanic corrosion. By providing adequate drainage, you can minimize the amount of moisture that comes into contact with the aluminum, reducing the risk of corrosion. 6. Regular Maintenance: Regularly inspect and maintain the aluminum sheets and their protective measures. If any damage or deterioration is observed, promptly repair or replace the barrier coatings, insulation, or surface treatments to ensure continued protection against galvanic corrosion. By implementing these preventive measures, you can significantly reduce the risk of galvanic corrosion when using aluminum sheets with concrete, prolonging the lifespan and integrity of the aluminum and the concrete structures.

- Q: Can aluminum sheets be used for elevator panels?

- Yes, aluminum sheets can be used for elevator panels. Aluminum is a versatile and durable material that is commonly used in construction and architectural applications, including elevator interiors. It offers several advantages such as being lightweight, corrosion-resistant, and easy to clean. Aluminum panels can be customized to fit the specific design requirements of elevator interiors and can be finished with different surface treatments or coatings to enhance their appearance and durability. Additionally, aluminum is a sustainable material as it is highly recyclable, making it an environmentally-friendly choice for elevator panels.

- Q: What is the flexural modulus of aluminum sheets?

- The measure of the stiffness or rigidity of aluminum sheets when subjected to bending or flexural stress is referred to as the flexural modulus. This mechanical property quantifies the aluminum sheet's resistance to deformation under applied force. Typically ranging between 69 GPa to 79 GPa, the flexural modulus of aluminum sheets depends on the specific alloy and temper. However, it is crucial to note that factors such as thickness, heat treatment, and manufacturing processes can cause slight variations in the flexural modulus. Aluminum is widely recognized for its exceptional strength-to-weight ratio, making it a favored choice for applications that require lightweight and durable materials. Due to its relatively high flexural modulus, aluminum sheets can maintain their shape and resist bending or flexing, making them suitable for uses in aircraft structures, automotive components, and building construction. It is important to highlight that the flexural modulus of aluminum can be improved through alloying elements or heat treatment processes. For instance, certain aluminum alloys like 7075 or 2024 may exhibit higher flexural modulus values due to their enhanced strength and stiffness properties. To summarize, the flexural modulus of aluminum sheets is a crucial mechanical property that determines their ability to withstand bending or flexural stress. This property provides valuable insights into the material's rigidity and assists engineers and designers in selecting the appropriate aluminum alloy and thickness for various applications.

- Q: Is it possible to utilize aluminum sheets as materials for car body panels?

- <p>Yes, aluminum sheets can be used for car body panels. They offer several advantages such as lightweight, high strength, and good corrosion resistance. Aluminum is also easily recyclable and can be shaped into complex designs. However, aluminum is less resistant to dents compared to steel, which is a common material for car body panels. Despite this, aluminum's benefits often outweigh its drawbacks, making it a popular choice in the automotive industry, especially for high-performance and electric vehicles where weight reduction is crucial.</p>

- Q: I saw a nice looking set of cast aluminum pots for a very good price. They feel very heavy. But I remember hearing that aluminum is not healthy so I am wary of buying them. Any advice would be appreciated.

- Cast Aluminum Pots

- Q: How does the purity of aluminum affect its properties as a sheet?

- The purity of aluminum plays a significant role in determining its properties as a sheet. Higher purity levels of aluminum generally result in improved mechanical properties, thermal and electrical conductivity, as well as better corrosion resistance. When aluminum is highly pure, meaning it has a low level of impurities, it becomes more malleable and ductile, making it easier to form into thin sheets. This makes highly pure aluminum sheets more suitable for applications where intricate shapes and designs are required. Additionally, the high electrical conductivity of pure aluminum makes it an excellent choice for electrical applications, such as wiring and circuit boards. It allows for efficient transmission of electricity and reduces the risk of overheating. Moreover, the thermal conductivity of pure aluminum makes it an ideal choice for heat transfer applications. Aluminum sheets with high purity can efficiently dissipate heat, making them well-suited for applications such as heat sinks and radiators. Furthermore, the corrosion resistance of aluminum increases with higher purity. Pure aluminum forms a protective oxide layer on its surface, which helps prevent corrosion and extends the lifespan of aluminum sheets in various environments. In summary, the purity of aluminum directly affects its properties as a sheet. Higher purity levels enhance its mechanical properties, electrical and thermal conductivity, as well as corrosion resistance, making it more versatile and suitable for a wide range of applications.

- Q: Is it possible to use adhesive instead of fasteners to bond aluminum sheets to a structure?

- <p>Yes, you can use an adhesive to attach aluminum sheets to a structure. However, it's important to choose an adhesive that is specifically designed for bonding aluminum, as not all adhesives provide the necessary strength and durability. Structural adhesives that are compatible with aluminum can offer a strong bond and are often used in applications where a clean, seamless appearance is desired or where fasteners are not suitable. It's crucial to ensure that the adhesive is resistant to the environmental conditions the structure will be exposed to, such as moisture, temperature fluctuations, and UV radiation. Always follow the manufacturer's instructions for surface preparation and application to achieve the best results.</p>

- Q: I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was built in 79.How much would it cost to replace? would walls have to come down to do it?

- It has loosing joints problem between aluminum wire and copper screw joint. Some house caught fire happen on the wall outlet or power panel box. All the joints must use aluminum screw to join aluminum wire. Join copper with aluminum,the joint creates thermo-effect and heat builds up.

Send your message to us

OEM Painted Aluminum Sheets 4x8 - Python Embossed Sheet for Automotive Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords