PVC Waterproofing Membrane with Stadium Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane with Stadium Material

Product Description of PVC Waterproofing Membrane with Stadium Material:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproofing Membrane with Stadium Material:

1. Excellent anti-aging property.

2. Puncture- resistant.

3. Welding construction,

4. High tensile strength, good elongation, good dimensional stability.

5. Good plasticity.

6. It has self-extinguishing from fire property.

7. Materials surface is smooth, fast color, stain resistance.

8. More wide, Wastage become less when being used.

Classification of PVC Waterproofing Membrane with Stadium Material:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Membrane with Stadium Material:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Membrane with Stadium Material:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Membrane with Stadium Material:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

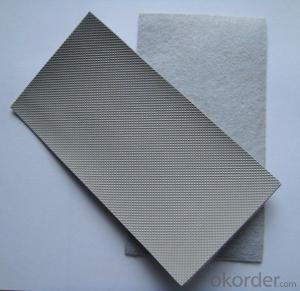

Images of PVC Waterproofing Membrane with Stadium Material:

FAQ of PVC Waterproofing Membrane with Stadium Material:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Yes, waterproofing membranes are typically resistant to chlorine exposure.

- Q: Can a waterproofing membrane be used for residential buildings or homes?

- Residential buildings or homes can indeed benefit from the use of a waterproofing membrane. Construction commonly relies on waterproofing membranes to safeguard against water infiltration, shielding both the structure and interior from moisture-induced harm. These versatile membranes find application in diverse areas like basements, roofs, foundations, and bathrooms, among others. By effectively blocking water, these membranes effectively thwart leaks, mold proliferation, and deterioration of building materials. Consequently, employing a waterproofing membrane proves highly efficacious in safeguarding the longevity and durability of residential buildings or homes.

- Q: Can a waterproofing membrane be used on below-grade structures, such as basements?

- Yes, a waterproofing membrane can be used on below-grade structures such as basements. In fact, it is highly recommended to install a waterproofing membrane on below-grade structures to prevent water infiltration and moisture problems. A waterproofing membrane acts as a barrier that prevents water from entering the basement walls and floors. It is typically made of materials such as bitumen, rubberized asphalt, or polyethylene, which are designed to be impermeable to water. The membrane is applied to the exterior or interior of the basement walls and floors, creating a watertight seal. This helps to eliminate the risk of water damage, mold growth, and structural issues caused by water penetration. Therefore, using a waterproofing membrane on below-grade structures like basements is essential to ensure a dry and safe living or storage space.

- Q: Is a waterproofing membrane resistant to hydrochloric acid or other corrosive substances?

- Waterproofing membranes are designed to resist water penetration and are commonly used as a barrier against moisture. However, it is important to understand that the resistance of a waterproofing membrane to hydrochloric acid or other corrosive substances may vary depending on the specific material used. Some waterproofing membranes, like those made from bituminous or rubberized asphalt materials, have a higher resistance to chemicals such as hydrochloric acid. These membranes are often utilized in industrial settings where exposure to corrosive substances is frequent. They are specifically engineered to endure the effects of these substances and offer long-lasting protection. On the contrary, other types of waterproofing membranes, such as those composed of polyvinyl chloride (PVC) or high-density polyethylene (HDPE), may have a lower resistance to corrosive substances like hydrochloric acid. These membranes are typically employed in less demanding applications where chemical exposure is not a significant concern. Regardless, it is essential to refer to the manufacturer's specifications and guidelines when assessing the resistance of a particular waterproofing membrane to hydrochloric acid or other corrosive substances. The manufacturer can provide detailed information on the membrane's chemical resistance properties and offer guidance on its suitability for specific applications involving corrosive substances.

- Q: Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They can effectively prevent water intrusion and protect homes from moisture damage, making them an ideal solution for basements, foundations, roofs, and other areas prone to water leakage.

- Q: Can a waterproofing membrane be used on tunnels with security systems?

- Indeed, tunnels with security systems can utilize a waterproofing membrane. It is strongly advised to employ a waterproofing membrane in tunnels, particularly those equipped with security systems, to safeguard the infrastructure and valuable equipment from water harm. Waterproofing membranes are specifically crafted to impede water infiltration, furnishing a protective shield against water leakage and potential complications stemming from moisture, such as corrosion, mold propagation, and structural degradation. By implementing a waterproofing membrane in tunnels featuring security systems, the integrity of the tunnel structure and the efficacy of the security systems can be upheld, guaranteeing the facility's safety and security.

- Q: How does a waterproofing membrane handle construction joints?

- A waterproofing membrane typically handles construction joints by providing a seamless and continuous barrier that seals and protects the joints from water infiltration. It is applied over the construction joint and adheres to both sides, ensuring no gaps or openings for water to enter. This helps to prevent water damage and maintain the structural integrity of the building or structure.

- Q: Can waterproofing membranes be used on concrete floors?

- Indeed, concrete floors can benefit from the utilization of waterproofing membranes. Within construction, these membranes hold a prevalent role in averting water infiltration and safeguarding the underlying structure. By implementing them onto concrete floors, a protective barrier arises, effectively thwarting water from permeating and causing harm. Significantly beneficial, waterproofing membranes prove their worth in spaces prone to water exposure, such as basements, bathrooms, and outdoor patios. Their presence ensures the concrete floor's durability while defending against moisture-related predicaments like cracking, spalling, and mold development.

- Q: Can a waterproofing membrane be used in bathrooms?

- Indeed, bathrooms can benefit greatly from the utilization of a waterproofing membrane. It is strongly advised to employ such a membrane in bathrooms as a preventive measure against water-related harm and leakage. Typically, this membrane is applied to both the walls and floors, establishing a protective barrier that inhibits water infiltration, subsequently averting structural deterioration or the proliferation of mold. This is particularly crucial in areas of heightened water exposure, such as showers and the vicinity of bathtubs. These waterproofing membranes are engineered to endure moisture and offer enduring safeguarding, thereby assuring the soundness of the bathroom and prolonging its longevity.

- Q: Are there any specific building code requirements for waterproofing membranes?

- Yes, there are specific building code requirements for waterproofing membranes. Building codes vary by jurisdiction, but most codes require that waterproofing membranes meet certain standards and specifications. These requirements are put in place to ensure that buildings are adequately protected from water damage and to maintain the safety and integrity of the structure. Some common building code requirements for waterproofing membranes include: 1. Material standards: The building code may specify the type of materials that can be used for waterproofing membranes. This can include specifications for the type of membrane, such as liquid-applied or sheet membranes, as well as the required thickness and composition. 2. Installation standards: The building code may outline specific installation methods and techniques for waterproofing membranes. This can include requirements for proper surface preparation, application procedures, and detailing around penetrations and transitions. 3. Testing and certification: Building codes may require that waterproofing membranes undergo certain tests and meet specific performance criteria. This can include tests for resistance to water penetration, durability, and compatibility with other building materials. In some cases, the code may require that the waterproofing membrane be certified by a recognized testing laboratory. 4. Code compliance documentation: Building codes often require that waterproofing membranes be installed in accordance with approved plans and specifications. This means that contractors may need to submit documentation to demonstrate compliance with the code, such as product data sheets, manufacturer's installation instructions, and details of the proposed waterproofing system. It is important to consult the local building code or regulatory authority to determine the specific requirements for waterproofing membranes in a particular jurisdiction. Compliance with these requirements is essential to ensure the proper functioning and longevity of the waterproofing system and to avoid potential issues such as water intrusion, mold growth, and structural damage.

Send your message to us

PVC Waterproofing Membrane with Stadium Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords