PVC Waterproof Membrane Nonwoven Polyester Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Brief Introdustion of PVC Waterproofing Membrane:

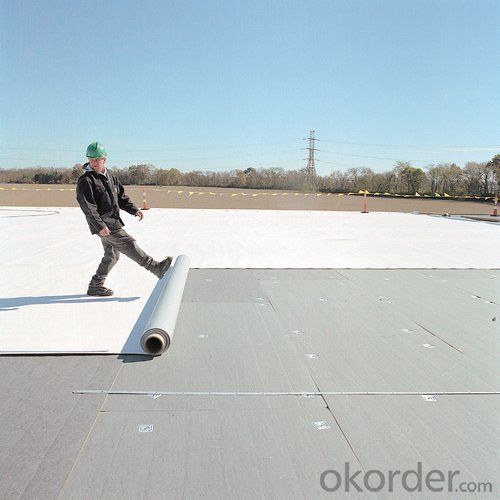

The P series waterproofing membrane is a heat-weldable membrane produced with an integral polyester reinforcement for high strength,for use in a Magical Stone's solution system. Its excellent performance of resistance to plasticizer extraction and migration, extend the product's life and more friendly to environment.

2. Features of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

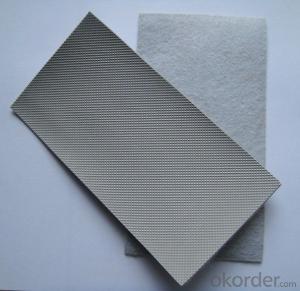

3. Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

4. Types of PVC Waterproofing Membrane

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric.

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

5. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be pre-fabricated or pre-made for easy installation?

- Yes, a waterproofing membrane can be pre-fabricated or pre-made for easy installation. Pre-fabricated membranes are manufactured in controlled environments, allowing for consistent quality and performance. They are designed to be installed quickly and easily, reducing labor time and cost. Pre-made membranes also ensure a precise fit and minimize the risk of installation errors. Overall, pre-fabricated or pre-made waterproofing membranes offer convenience and efficiency in the installation process.

- Q: Can a waterproofing membrane be used in roofs?

- Roofs can indeed benefit from the use of a waterproofing membrane. It's a widely employed technique for safeguarding roofs against water-related harm. Typically composed of robust materials like rubber or modified bitumen, this membrane is applied to the roof's surface to establish a barrier that prevents water from seeping through. As a result, leaks and potential damage are averted, as this protective layer stops water from penetrating the roof's underlying structure. Waterproofing membranes are particularly advantageous for flat or low-sloped roofs, where water accumulation is prone to causing issues. Moreover, these versatile membranes can be utilized on diverse roofing materials, including concrete, metal, and asphalt, making them suitable for various roof types. Overall, incorporating a waterproofing membrane into roofs effectively enhances their durability and longevity, while ensuring dependable protection against water infiltration.

- Q: Can a waterproofing membrane be used for a residential building?

- A residential building can utilize a waterproofing membrane for its protection. This membrane is a thin material layer applied to the building's exterior walls, foundation, or roof to prevent water from entering the structure. It acts as a barrier against moisture, preventing water damage, mold growth, and enhancing energy efficiency by reducing heat loss. The implementation of a waterproofing membrane in a residential building can be done in multiple areas like basements, bathrooms, balconies, roofs, and exterior walls. It is particularly beneficial in areas prone to water infiltration, such as basements where groundwater seepage may occur or bathrooms where moisture problems can arise from water splashes and steam. Various types of waterproofing membranes are available, including liquid-applied membranes, sheet membranes, and self-adhering membranes. These membranes are designed to be long-lasting, flexible, and resistant to water, ensuring durability and effectiveness in protecting the residential building. By utilizing a waterproofing membrane, homeowners can safeguard their property from water damage, structural issues, and health risks associated with moisture intrusion. It is crucial to seek professional advice to determine the most suitable type of waterproofing membrane for the residential building based on factors like location, climate, and potential sources of water infiltration.

- Q: Can a waterproofing membrane be used on gypsum board surfaces?

- Yes, a waterproofing membrane can be used on gypsum board surfaces. Gypsum board, also known as drywall, is a common material used in interior construction. While it is not inherently waterproof, applying a waterproofing membrane can help protect the gypsum board from moisture damage. A waterproofing membrane is a thin layer of material that is applied to the surface of the gypsum board. It forms a barrier that prevents water from seeping into the board and causing it to deteriorate or mold. It can be used in areas where moisture is present, such as bathrooms, kitchens, laundry rooms, or basements. Before applying a waterproofing membrane, it is important to prepare the gypsum board surface properly. This may involve cleaning the surface, patching any holes or cracks, and ensuring the board is dry and free of dust. Once the surface is ready, the waterproofing membrane can be applied according to the manufacturer's instructions. It is worth noting that while a waterproofing membrane can provide some protection against moisture, it is not a guarantee against water damage. It is always important to address the source of water intrusion and ensure proper drainage and ventilation in any area prone to moisture. Additionally, it is recommended to consult with a professional or follow the manufacturer's recommendations when choosing and applying a waterproofing membrane to gypsum board surfaces.

- Q: How do waterproofing membranes prevent water leakage?

- Waterproofing membranes are designed to prevent water leakage by creating a barrier between the surface and the water. These membranes are typically made of materials such as bitumen, PVC, or EPDM, and are applied to the surface in a liquid or sheet form. The primary way in which waterproofing membranes prevent water leakage is by forming a continuous and impermeable layer. This layer acts as a physical barrier that prevents water from seeping through the surface. The membranes are applied in such a way that they cover the entire surface, including joints, cracks, and seams, ensuring that there are no areas vulnerable to water penetration. Additionally, waterproofing membranes often have excellent adhesive properties, allowing them to bond tightly to the surface. This ensures that there are no gaps or spaces where water could enter. By adhering tightly to the surface, the membranes also provide protection against the movement of water vapor, preventing moisture buildup and potential damage to the structure. Furthermore, waterproofing membranes are specifically designed to be highly resistant to water and moisture. They are made from materials that do not degrade or deteriorate when exposed to water, ensuring their longevity and effectiveness. This resistance to water also helps to prevent the membrane from becoming permeable over time. In summary, waterproofing membranes prevent water leakage by creating a continuous and impermeable barrier on the surface. They cover the entire surface, adhere tightly to prevent gaps, and are resistant to water and moisture. By implementing these measures, waterproofing membranes provide reliable protection against water infiltration and subsequent damage.

- Q: Can a waterproofing membrane be used in areas with high levels of salt or saltwater exposure?

- Indeed, areas with high levels of salt or saltwater exposure can benefit from the utilization of a waterproofing membrane. Nevertheless, it is imperative to opt for a membrane specifically engineered to endure these particular conditions. There exist certain waterproofing membranes that are specially concocted to resist the harmful effects of salt and saltwater exposure, effectively thwarting any potential harm or deterioration. Typically, these membranes are crafted using corrosion-resistant materials that possess heightened durability. To guarantee long-term efficacy and protection, it is absolutely crucial to seek professional guidance in selecting the appropriate type of waterproofing membrane for areas prone to high salt or saltwater exposure.

- Q: Can a waterproofing membrane be used for a parking lot pavement?

- Yes, a waterproofing membrane can be used for a parking lot pavement. A waterproofing membrane is a layer of material that is applied to a surface to prevent the ingress of water. This membrane is typically used in building construction to protect walls, roofs, and foundations from water damage. However, it can also be used in parking lot pavements to enhance their durability and longevity. Parking lots are exposed to various weather conditions, including rain, snow, and ice. These elements can seep through the pavement and cause damage over time, leading to cracks, potholes, and deterioration. By applying a waterproofing membrane to the pavement, water infiltration can be significantly reduced, preventing these issues from occurring. The waterproofing membrane acts as a barrier, preventing water from penetrating the pavement and reaching the underlying layers. It keeps the pavement dry, preventing moisture-related problems such as freeze-thaw damage. Additionally, it helps to protect the pavement from chemicals, oils, and other substances that may be spilled on the surface. Using a waterproofing membrane for a parking lot pavement can extend its lifespan and reduce the need for frequent repairs and maintenance. It can also improve the overall aesthetics of the parking lot by preventing unsightly cracks and potholes. However, it is important to note that the choice of a waterproofing membrane should be made based on the specific requirements of the parking lot. Factors such as traffic load, climate, and the type of pavement material should be taken into consideration to ensure the effectiveness and longevity of the waterproofing system. In conclusion, a waterproofing membrane can be a suitable solution for enhancing the performance and durability of a parking lot pavement. It can provide protection against water damage, extend the lifespan of the pavement, and reduce the need for expensive repairs.

- Q: Can a waterproofing membrane be used in conjunction with warranty or insurance policies?

- Typically, a waterproofing membrane can be used alongside warranty or insurance policies. Various waterproofing products and systems come with warranties that offer coverage for a specific duration, typically ranging from 5 to 20 years or even longer. These warranties often guarantee the effectiveness and durability of the waterproofing membrane, and may include provisions for repairs or replacements in the event of any failures or defects. Moreover, insurance policies may also provide coverage for damages caused by water leaks or flooding. By installing a waterproofing membrane, property owners can minimize the risk of water damage and potentially lower their insurance premiums. It is advisable to inquire with your insurance provider to determine if they offer any discounts or incentives for utilizing waterproofing systems. Nevertheless, it is crucial to note that the coverage provided by warranties and insurance policies may vary based on specific terms and conditions. It is recommended that you carefully review the details of the warranty or insurance policy and seek guidance from professionals to ensure that the waterproofing membrane aligns with the requirements and specifications outlined in these agreements.

- Q: Can a waterproofing membrane be used in ponds or reservoirs?

- Yes, a waterproofing membrane can be used in ponds or reservoirs. Waterproofing membranes are designed to create a barrier that prevents water from seeping through, making them an effective solution for creating a watertight seal in ponds or reservoirs.

- Q: How does a waterproofing membrane handle exposure to UV rays?

- In order to handle exposure to UV rays, a waterproofing membrane is designed with the incorporation of UV stabilizers and additives into its composition. These UV stabilizers function by either absorbing or reflecting the harmful UV rays, thus preventing any degradation or damage to the membrane. Over time, the UV rays emitted by the sun can be extremely intense and lead to the deterioration of various materials. Continuous exposure of a waterproofing membrane to these UV rays can result in a process known as photo-oxidation. During this process, the energy from the UV rays interacts with the molecular structure of the membrane, causing it to weaken and break down. To counteract this issue, manufacturers include UV stabilizers in the membrane during the manufacturing process. These stabilizers act as a shield, absorbing or reflecting the UV rays and ensuring they do not reach the surface of the membrane. By doing so, the stabilizers slow down the process of photo-oxidation, effectively extending the lifespan of the waterproofing membrane. Furthermore, some waterproofing membranes may possess an additional protective layer or coating that enhances their resistance to UV rays. This layer acts as an extra barrier, shielding the membrane from direct exposure to UV rays and further improving its durability and lifespan. However, it is important to note that despite the presence of UV stabilizers and protective coatings, prolonged exposure to intense UV rays can still lead to some degree of degradation or discoloration over time. Therefore, it is advisable to regularly inspect and maintain the waterproofing membrane to ensure its effectiveness and address any signs of UV damage promptly.

Send your message to us

PVC Waterproof Membrane Nonwoven Polyester Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords