Polyvinyl Chloride (PVC) Waterproofing Membrane of Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

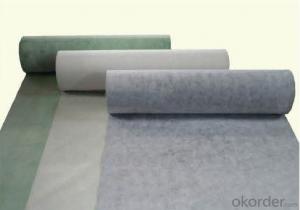

1. Introduction of PVC Waterproofing Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

2. Features of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

3. Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

4. Types of PVC Waterproofing Membrane

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric.

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

5. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used on roofs with skylights?

- Yes, a waterproofing membrane can be used on roofs with skylights. The membrane is typically installed around the skylight opening to ensure a watertight seal and prevent any leaks or water damage.

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Yes, a waterproofing membrane does require special considerations for installation in seismic zones. Seismic zones are prone to earthquakes and ground movements, which can cause significant stress and strain on the building structure. When installing a waterproofing membrane in such areas, it is crucial to ensure that it can withstand the potential movements and vibrations caused by seismic activities. Some of the special considerations for installing a waterproofing membrane in seismic zones include: 1. Flexibility: The membrane should have sufficient flexibility to accommodate the movement of the building structure during an earthquake. It should be able to stretch, contract, and withstand dynamic forces without tearing or losing its waterproofing properties. 2. Compatibility: The waterproofing membrane should be compatible with the building materials and systems used in seismic zones. It is important to select a membrane that can bond well with the substrate and other construction components to create a seamless and robust waterproofing system. 3. Reinforcement: In high seismic areas, it is recommended to reinforce the waterproofing membrane with additional layers or reinforcements. This can be done by adding a fabric or mesh layer to enhance the membrane's tensile strength and resistance to tearing caused by seismic movements. 4. Proper installation techniques: The installation of the waterproofing membrane in seismic zones should follow specific guidelines and techniques to ensure its effectiveness. It may involve using specific adhesives, primers, or mechanical fastening systems to secure the membrane properly. 5. Quality control: Regular inspections and quality control measures should be implemented during and after the installation process. This helps to identify any potential issues or deficiencies in the waterproofing system, allowing for prompt repairs or adjustments to be made. By addressing these special considerations, the installation of a waterproofing membrane in seismic zones can help protect the building structure from water intrusion and potential damage caused by earthquakes. Consulting with experienced professionals and following industry standards and guidelines is crucial to ensure a successful installation in these challenging environments.

- Q: Can a waterproofing membrane be used on steel surfaces?

- Yes, a waterproofing membrane can be used on steel surfaces. Waterproofing membranes are designed to create a barrier against moisture and water infiltration, and they can be applied to various surfaces, including steel. Steel surfaces are commonly found in construction projects, such as roofs, balconies, and foundations. Applying a waterproofing membrane on steel surfaces helps to prevent corrosion and damage caused by water exposure. It is important to select a waterproofing membrane that is suitable for steel surfaces and ensure proper surface preparation and application techniques for optimal performance and durability.

- Q: Can a waterproofing membrane be used on roofs with flat surfaces?

- Roofs with flat surfaces can indeed benefit from the application of a waterproofing membrane. In fact, it is quite common to use these membranes on flat roofs to safeguard against water infiltration. The primary function of these membranes is to establish a barrier that obstructs water from seeping into the roof structure and causing harm. Typically, they are constructed using materials like modified bitumen, EPDM, or PVC, which exhibit great resistance to both water and UV rays. To install the membrane, it can be done by torch-application, adhesive adherence, or mechanical fastening. To ensure optimal effectiveness and longevity of the waterproofing membrane on a flat roof, it is crucial to guarantee proper installation and regular maintenance.

- Q: Can waterproofing membranes be used on mechanical equipment rooms?

- Yes, waterproofing membranes can be used on mechanical equipment rooms. Waterproofing membranes are commonly used to protect various types of structures, including mechanical equipment rooms, from water damage. These membranes create a protective barrier that prevents water infiltration, ensuring the longevity and proper functioning of the equipment and reducing the risk of water-related issues such as corrosion or electrical damage.

- Q: Can a waterproofing membrane be used for vehicular traffic areas?

- Vehicular traffic areas can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a barrier that prevents water from seeping through and causing damage to surfaces. In areas like parking decks or driveways, it is crucial to protect the underlying structure from water infiltration, which can lead to corrosion, deterioration, and expensive repairs. By utilizing a waterproofing membrane that is specifically designed for vehicular traffic, the surface can be effectively safeguarded from water damage, as well as other potential contaminants such as oil and chemicals. These membranes are typically more durable and capable of withstanding the weight and impact of vehicles, ensuring long-lasting protection. Furthermore, certain waterproofing membranes even offer slip-resistant properties, making them suitable for areas where vehicles require traction. Nevertheless, it is important to seek guidance from a professional to determine the appropriate waterproofing membrane and installation method for specific vehicular traffic areas, taking into account factors such as traffic volume, load capacity, and climate conditions.

- Q: Can a waterproofing membrane be used for balconies and terraces?

- Balconies and terraces can benefit greatly from the application of a waterproofing membrane. This is due to the fact that these areas are constantly exposed to outdoor elements like rain, snow, and sunlight, all of which can lead to the accumulation of moisture and the deterioration of the underlying structure. To prevent water penetration and subsequent damage, it is highly recommended to utilize a waterproofing membrane. By acting as a barrier, this protective layer prevents water from seeping through the surface, thus avoiding potential leaks, mold growth, or structural harm. Not only does this guarantee the long-lasting and sturdy nature of the balcony or terrace, but it also provides a wide range of options in terms of types and materials. This flexibility allows for the selection of the most suitable waterproofing membrane that aligns with the specific requirements of the balcony or terrace.

- Q: What is the typical installation process for a waterproofing membrane?

- The typical installation process for a waterproofing membrane involves several steps. First, the surface to be waterproofed is cleaned and prepared, ensuring it is free from debris, dirt, and any loose materials. Next, a primer is applied to enhance the adhesion of the membrane. The waterproofing membrane is then unrolled and carefully laid onto the surface, ensuring it is aligned correctly. It is commonly secured using adhesive or mechanical fasteners. Any overlaps or joints are properly sealed using a compatible sealant or tape. Finally, a protective layer, such as a geotextile fabric or drainage board, may be added to enhance the durability and performance of the waterproofing system. Overall, the installation process requires attention to detail and adherence to manufacturer guidelines to ensure a successful waterproofing solution.

- Q: Are waterproofing membranes environmentally friendly?

- Depending on the type and installation, waterproofing membranes have the potential to be environmentally friendly. Some membranes are manufactured with recycled materials, which reduces the need for new resources and waste generation. Moreover, certain membranes are designed for durability and longevity, reducing the frequency of replacement and overall environmental impact. Nevertheless, it is crucial to consider the potential adverse environmental effects of waterproofing membranes. Some membranes are composed of synthetic materials that may release harmful chemicals into the environment during production or degradation. Furthermore, improper installation or disposal of these membranes can result in pollution and contamination of soil and water sources. To ensure the environmental friendliness of waterproofing membranes, it is essential to select products certified as sustainable or eco-friendly by reputable organizations. Additionally, hiring experienced professionals for correct installation minimizes the risk of leaks or damage that could lead to environmental issues. Lastly, proper disposal of old or damaged membranes is vital to prevent pollution and ensure responsible waste management. In conclusion, waterproofing membranes can be environmentally friendly if appropriate materials are chosen, installation is performed correctly, and disposal is handled responsibly. It is crucial to assess the environmental impact of these membranes and make informed choices to minimize any negative effects.

- Q: Can a waterproofing membrane be used in stadiums or sports complexes?

- Stadiums and sports complexes can indeed benefit from the use of waterproofing membranes. It is highly advisable to employ waterproofing solutions in these types of structures to safeguard them against water damage and leaks. The purpose of a waterproofing membrane is to serve as a barrier, preventing water from infiltrating the concrete or other construction materials employed in the stadium or sports complex. This is especially crucial in regions where heavy rainfall or high humidity levels are prevalent. Implementation of a waterproofing membrane on the roofs, walls, and foundations of these edifices helps guarantee their longevity and structural integrity, while also offering a comfortable and secure environment for athletes and spectators alike. Waterproofing membranes are specifically designed to endure the pressures and movements associated with the building, making them an optimal choice for stadiums and sports complexes. Additionally, contemporary waterproofing membranes come in diverse forms, including liquid-applied or sheet membranes. This allows for flexibility in application and compatibility with various construction materials.

Send your message to us

Polyvinyl Chloride (PVC) Waterproofing Membrane of Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords