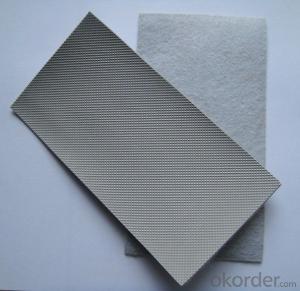

High Polymer Waterproofing Membrane Polyester Nonwoven Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

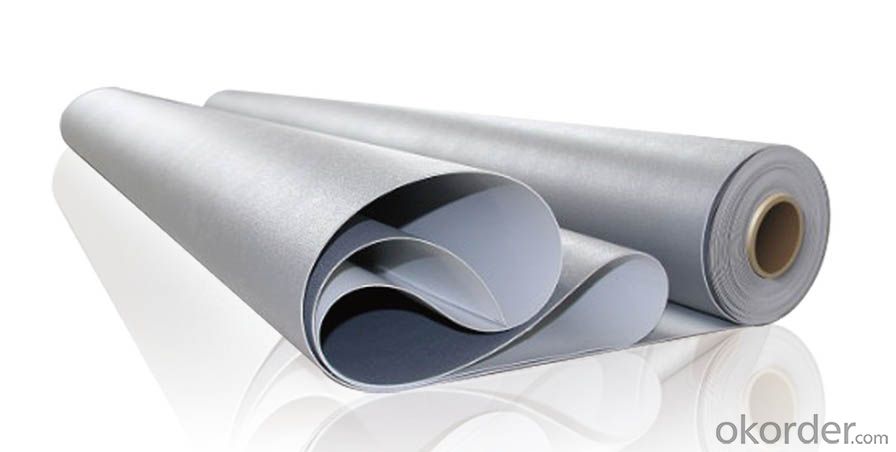

Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

Introduction of PVC Waterproofing Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Features of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

Types of PVC Waterproofing Membrane

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric.

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used in saunas?

- Yes, a waterproofing membrane can be used in saunas to protect the underlying structure from moisture and prevent water damage.

- Q: Are waterproofing membranes suitable for historical buildings?

- Under certain circumstances, historical buildings can benefit from the use of waterproofing membranes. These membranes are specifically designed to safeguard structures against water damage, which is especially important for historical buildings that may have aged and porous materials. However, the suitability of waterproofing membranes for historical buildings relies on a variety of factors. First and foremost, it is vital to take into account the unique requirements and characteristics of the historical building in question. Each building possesses distinct materials and features, and the impact of waterproofing on these elements must be thoroughly assessed. Some older structures may possess delicate architectural elements or materials that could be adversely influenced by the application of waterproofing membranes. In such instances, alternative methods that are less intrusive or damaging may be more appropriate. Secondly, it is essential to seek guidance from conservation experts or professionals who specialize in the preservation of historical buildings. These experts can evaluate the specific needs of the building and offer advice on the most suitable waterproofing techniques. They can also ensure that any interventions are executed in a manner that respects the historical integrity and authenticity of the structure. Lastly, it is crucial to consider the long-term consequences of waterproofing membranes on historical buildings. While these membranes can effectively protect against water damage, they may also compromise the natural breathability of the building, potentially leading to moisture accumulation and further deterioration. Therefore, it is imperative to carefully balance the benefits of waterproofing with the potential risks and long-term effects. In conclusion, while waterproofing membranes can be appropriate for historical buildings, caution should be exercised when applying them. A thorough assessment of the building's specific requirements, consultation with preservation experts, and consideration of long-term implications are essential in determining the suitability of waterproofing membranes for historical structures.

- Q: Can waterproofing membranes be used on elevator shafts?

- Yes, waterproofing membranes can be used on elevator shafts to prevent water infiltration and protect the structure from moisture damage.

- Q: Can a waterproofing membrane be used on roofs with rooftop gardens?

- Yes, a waterproofing membrane can be used on roofs with rooftop gardens. The membrane serves as a protective layer that prevents water from seeping into the underlying structure, ensuring that the rooftop garden remains dry and well-maintained.

- Q: Are waterproofing membranes suitable for stadium structures?

- Yes, waterproofing membranes are suitable for stadium structures. Stadiums are exposed to various weather conditions such as rain, snow, and humidity, which can potentially damage the structure if proper waterproofing measures are not taken. Waterproofing membranes provide a protective layer that prevents water infiltration, thus safeguarding the stadium from moisture-related issues like leaks, mold, and corrosion. Stadium structures often have large roof areas and expansive seating areas where water can accumulate, making waterproofing crucial. Membranes can be applied on various surfaces, including concrete, metal, and wood, ensuring a versatile and effective waterproofing solution for stadiums. Moreover, waterproofing membranes offer durability and longevity, which is essential for stadiums that are subjected to heavy usage and constant exposure to the elements. They are designed to withstand thermal expansion and contraction, as well as UV radiation, ensuring long-term protection for the structure. Additionally, waterproofing membranes can be customized to meet specific design requirements, allowing architects and engineers to integrate them seamlessly into the stadium's overall aesthetic. These membranes come in various colors, textures, and finishes, enabling them to blend with the surrounding materials and enhance the visual appeal of the stadium. Overall, waterproofing membranes provide a reliable and effective solution for protecting stadium structures from water damage. They offer durability, versatility, and customization options, making them suitable for any stadium construction or renovation project.

- Q: Can waterproofing membranes be used in basements?

- Yes, waterproofing membranes can be used in basements. Waterproofing membranes are commonly used in basements to prevent water intrusion and dampness. By applying these membranes on the walls and floors of the basement, they create a barrier that prevents moisture from seeping into the basement, helping to keep the space dry and protected from water damage.

- Q: Can a waterproofing membrane be used for a school building foundation?

- A school building foundation can indeed utilize a waterproofing membrane. These membranes are specifically created to safeguard structures by preventing water from infiltrating. They are commonly employed in various construction scenarios, including building foundations. By applying a waterproofing membrane to the foundation walls, it can effectively shield the building from water-related harm and prevent issues caused by moisture, such as mold, decay, and structural damage. This is especially crucial for school buildings due to their extensive foundations and the possibility of heavy usage and water exposure. Thus, the use of a waterproofing membrane is a viable solution to ensure the durability and structural soundness of the school building foundation.

- Q: Can a waterproofing membrane be used in conjunction with solar panel installations?

- Yes, a waterproofing membrane can be used in conjunction with solar panel installations. Waterproofing membranes are commonly used to protect roofs and other surfaces from water damage, and they can provide an additional layer of protection for solar panels. This can help to prevent water infiltration and potential damage to the solar panels and their electrical components. Additionally, waterproofing membranes can also help to extend the lifespan of the solar panel system by providing an extra barrier against moisture and other environmental factors.

- Q: Can a waterproofing membrane be used in government or municipal projects?

- Yes, a waterproofing membrane can be used in government or municipal projects. In fact, it is a common practice to use waterproofing membranes in various infrastructure projects such as bridges, tunnels, parking structures, and government buildings. These membranes provide a reliable and durable solution to prevent water infiltration, protect the structural integrity of the project, and extend its lifespan. Additionally, waterproofing membranes can meet the necessary regulations and standards required for government or municipal projects.

- Q: How to choose waterproof membrane

- Fourth, the product price comparison Waterproof membrane products, intense competition, fake rampant to the production market, the largest amount of SBS modified asphalt waterproofing membrane, for example, the best profits are super but 15%. On the market there are many high-priced SBS modified asphalt waterproofing membrane, the SBS content is very small, even without SBS, with waste rubber powder to replace. Therefore, when buying, try to avoid the selection of products significantly lower than the market price.

Send your message to us

High Polymer Waterproofing Membrane Polyester Nonwoven Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords