Polyvinyl Chloride (PVC) Waterproofing Membrane Polyester Scrim Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

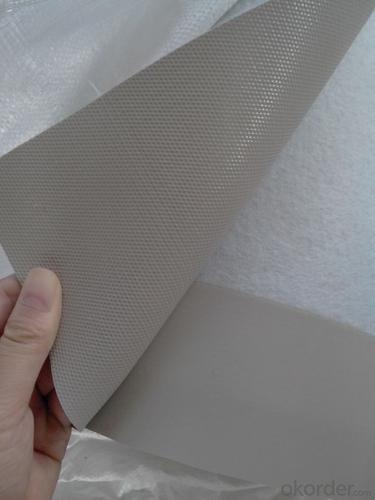

1. Introduction of PVC Waterproofing Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

2. Features of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

3. Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

4. Applications of PVC Waterproofing Membrane

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

5. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for a green roof?

- Certainly, a green roof can utilize a waterproofing membrane. The presence of a waterproofing membrane is indispensable for every green roof system due to its ability to shield the underlying structure from water-related harm. It serves the purpose of barring water seepage, which could potentially result in both structural deterioration and the growth of mold. Furthermore, a waterproofing membrane aids in preserving the requisite moisture within the green roof system, thereby guaranteeing a steady water source for the plants. By incorporating a waterproofing membrane, one can successfully establish an eco-friendly and sustainable green roof, all while upholding the structural integrity of the building.

- Q: Can a waterproofing membrane be used on precast chrome surfaces?

- Yes, a waterproofing membrane can be used on precast chrome surfaces. The membrane will provide a protective barrier against water penetration, ensuring the durability and longevity of the precast chrome surfaces.

- Q: Can a waterproofing membrane be used in conjunction with concrete repair or restoration?

- Yes, a waterproofing membrane can be used in conjunction with concrete repair or restoration. In fact, it is often recommended to use a waterproofing membrane as a protective layer over repaired or restored concrete surfaces. This is because concrete repair or restoration may involve the removal of damaged or deteriorated areas, which can compromise the waterproofing properties of the original concrete. By applying a waterproofing membrane, you can ensure that the repaired or restored concrete remains protected against water intrusion, which can lead to further damage and deterioration. Additionally, the waterproofing membrane can also help to enhance the overall durability and longevity of the concrete structure.

- Q: Can a waterproofing membrane be used for a commercial building?

- Yes, a waterproofing membrane can be used for a commercial building. Waterproofing membranes are specifically designed to protect structures from water damage. They are commonly used in various commercial applications such as roofs, basements, and foundation walls. The membrane acts as a barrier that prevents water from infiltrating the building, thus protecting it from potential leaks, moisture buildup, and mold growth. Additionally, waterproofing membranes are durable and can withstand harsh weather conditions, making them suitable for commercial buildings that are exposed to heavy rainfall or extreme temperatures. Overall, using a waterproofing membrane in a commercial building is an effective way to ensure long-term structural integrity and prevent costly water-related damage.

- Q: Can a waterproofing membrane be used in conjunction with paint or coatings?

- Yes, a waterproofing membrane can be used in conjunction with paint or coatings. In fact, combining a waterproofing membrane with paint or coatings is a common practice in many construction and renovation projects. The waterproofing membrane provides a barrier against moisture and prevents water infiltration, while the paint or coatings add aesthetic appeal and can provide additional protection against UV rays, weathering, and chemical exposure. By using both in conjunction, you can achieve a dual-layer protection system that ensures long-lasting durability and water resistance. However, it is essential to ensure compatibility between the waterproofing membrane and the paint or coatings to avoid any adverse reactions or loss of effectiveness. Consult with a professional or manufacturer guidelines to determine the best combination and application process for your specific project.

- Q: Can waterproofing membranes be used on both horizontal and vertical surfaces?

- Waterproofing membranes possess the capability to be utilized on both horizontal and vertical surfaces. These membranes have been specifically engineered to furnish a protective shield against water infiltration, and they can be implemented on a diverse array of surfaces, encompassing roofs, walls, floors, and even subterranean structures. Their application is incredibly versatile, enabling them to safeguard horizontal surfaces, such as flat roofs or balconies, while also affording protection to vertical surfaces, including walls or foundations. The adaptability and resilience of waterproofing membranes render them highly suitable for a vast spectrum of construction projects, guaranteeing that water does not permeate and inflict harm upon the structure.

- Q: Can a waterproofing membrane be used in earthquake-prone areas?

- Yes, a waterproofing membrane can be used in earthquake-prone areas. In fact, it is highly recommended to use a waterproofing membrane in such areas to protect buildings and structures from potential water damage caused by earthquakes. Waterproofing membranes are designed to create a barrier against water infiltration, which can be crucial in preventing structural damage and maintaining the integrity of a building during seismic events. Additionally, these membranes can also provide some level of flexibility and elasticity, which can help absorb and distribute the forces exerted during an earthquake, reducing the risk of cracks and leaks. However, it is important to ensure that the waterproofing membrane used is specifically designed and tested to meet the requirements of earthquake-prone areas, considering factors such as the intensity and frequency of seismic activity in the region. Consulting with a structural engineer or a waterproofing specialist is highly recommended to determine the most suitable waterproofing system for earthquake-prone areas.

- Q: Can a waterproofing membrane be used in hot climates?

- Yes, a waterproofing membrane can be used in hot climates. In fact, it is essential to use a waterproofing membrane in areas with high temperatures and intense sunlight. The membrane provides protection against water intrusion, which is crucial in preventing damage to structures such as roofs, balconies, or basements. Additionally, a high-quality waterproofing membrane is designed to withstand the effects of temperature fluctuations and UV radiation, ensuring its longevity and effectiveness even in hot climates. Therefore, using a waterproofing membrane is highly recommended in hot climates to ensure the durability and integrity of the structures it is applied to.

- Q: Can a waterproofing membrane be used for a deck?

- Certainly! A deck can indeed benefit from the utilization of a waterproofing membrane. These membranes are frequently employed to shield surfaces from water-related harm by forming a barrier that hinders water infiltration. In the case of a deck, the application of a waterproofing membrane can effectively impede water seepage into the underlying structure, thereby averting issues like decay, distortion, and other types of damage. It is imperative to select a waterproofing membrane specifically crafted for outdoor usage, capable of enduring various elements such as UV rays, temperature fluctuations, and considerable foot traffic. Furthermore, the proper installation and maintenance of the waterproofing membrane on the deck play a pivotal role in ensuring its efficacy and prolonged lifespan.

- Q: Can a waterproofing membrane be used for a water tank sealant?

- Indeed, a waterproofing membrane can serve as a sealant for water tanks. These membranes are specifically engineered to obstruct water flow and are extensively employed for sealing diverse structures, such as water tanks. They furnish a robust and efficient shield against water penetration, thus safeguarding the tank from leaks and potential harm. Nevertheless, it is crucial to verify that the chosen waterproofing membrane is explicitly designed for water tanks and adheres to the required standards and regulations for the particular use. Additionally, it is advisable to seek guidance from a professional or a reputable manufacturer to guarantee the utilization of the correct product and installation technique for optimal performance and longevity.

Send your message to us

Polyvinyl Chloride (PVC) Waterproofing Membrane Polyester Scrim Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords