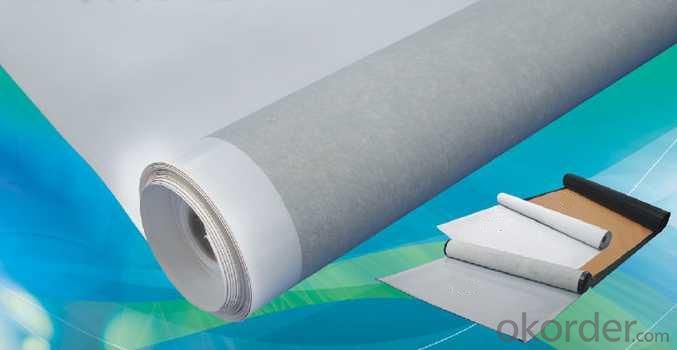

PVC Waterproofing Membrane Polyester Scrim Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction for PVC Waterproofing Membrane

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

2.Technical data of PVC Membrane

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

3.Characteristic of PVC Membrane

1.Strong tensile strength, high elongation, can fit big deformation of substrates.

2.Excellent anti-extreme weather property, can adapt to various environment temperature difference.

3.Suitable for exposed projects with long lifetime and good anti-aging property.

4.Can be welded firmly and reliably.

5.Outstanding root penetration resistance, best choice for planted roofs.

6.Simple and fast construction without pollution.

7.Great plasticity and fast treatment with corners and details.

4.Applicable scope of PVC Membrane

PVC sheet forms an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway& tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

5. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used in areas with high humidity and moisture?

- Yes, a waterproofing membrane can be used in areas with high humidity and moisture. The purpose of a waterproofing membrane is to provide a protective barrier against water and moisture, making it suitable for such environments. It helps prevent water infiltration, mold growth, and damage caused by excessive moisture, making it an ideal solution for humid and moisture-prone areas.

- Q: Can waterproofing membranes be used on outdoor patios?

- Yes, waterproofing membranes can be used on outdoor patios. They are an effective way to protect the patio from water damage and can help to prevent leaks and moisture penetration. Waterproofing membranes create a barrier between the patio surface and water, keeping it dry and extending its lifespan.

- Q: Can a waterproofing membrane be used on metal block surfaces?

- Metal block surfaces can indeed benefit from the use of a waterproofing membrane. These membranes are specifically designed to form a barrier against water and moisture, and they are versatile enough to be applied to various types of surfaces, including metal. By adhering to the metal surface, the membrane creates a protective layer that not only prevents water infiltration but also safeguards the metal against rust and corrosion. However, it is crucial to guarantee that the metal surface is thoroughly cleaned, dried, and appropriately prepared before the application of the waterproofing membrane. This preparation ensures optimal adhesion and effectiveness. For specific instructions on using a waterproofing membrane on metal block surfaces, it is highly recommended to consult a professional or refer to the manufacturer's guidelines.

- Q: Does a waterproofing membrane prevent water vapor transmission?

- Yes, a waterproofing membrane is designed to prevent both liquid water and water vapor from penetrating through a surface. It acts as a barrier that blocks the movement of moisture, including water vapor, thus preventing water intrusion and potential damage to the underlying structure. Waterproofing membranes are commonly used in various applications such as roofs, basements, and bathrooms to ensure the integrity and durability of the building envelope.

- Q: Are waterproofing membranes suitable for historical buildings?

- Waterproofing membranes can be suitable for historical buildings under certain circumstances. These membranes are designed to protect structures from water damage, which can be particularly important for historical buildings that may have aged and porous materials. However, the suitability of waterproofing membranes for historical buildings depends on various factors. Firstly, it is crucial to consider the specific needs and requirements of the historical building in question. Each building has unique characteristics and materials, and the impact of waterproofing on these elements must be carefully evaluated. Some older structures may have delicate architectural features or materials that could be negatively affected by the application of waterproofing membranes. In such cases, alternative methods that are less intrusive or damaging may be more appropriate. Secondly, it is important to consult with conservation experts or professionals who specialize in historical building preservation. These experts can assess the specific needs of the building and provide guidance on the most suitable waterproofing methods. They can also ensure that any interventions are carried out in a manner that respects the historical integrity and authenticity of the structure. Lastly, it is crucial to consider the long-term implications of waterproofing membranes on historical buildings. While they can provide effective protection against water damage, they may also alter the natural breathability of the building, potentially leading to moisture buildup and further deterioration. Therefore, it is essential to carefully balance the benefits of waterproofing with the potential risks and long-term consequences. In summary, waterproofing membranes can be suitable for historical buildings, but their application should be approached with caution. An assessment of the building's specific needs, consultation with preservation experts, and consideration of long-term implications are critical in determining the appropriateness of waterproofing membranes for historical structures.

- Q: Can a waterproofing membrane be used on zinc surfaces?

- Yes, a waterproofing membrane can be used on zinc surfaces. Zinc is a durable and corrosion-resistant material, and a waterproofing membrane can provide an additional layer of protection against water infiltration, ensuring the longevity and integrity of the zinc surface.

- Q: Can a waterproofing membrane be used for water tanks or reservoirs?

- Yes, a waterproofing membrane can be used for water tanks or reservoirs. Waterproofing membranes are designed to create a barrier that prevents water from penetrating through the surface. They are commonly used in various applications, including water tanks and reservoirs, to ensure that the stored water remains contained and does not leak or seep into the surrounding environment. The membrane is typically applied on the interior surface of the tank or reservoir, providing a durable and watertight seal. This helps to maintain the integrity of the water storage system and prevent any potential water loss or contamination. Additionally, waterproofing membranes can also protect the tank or reservoir from corrosion and structural damage caused by water exposure, extending their lifespan. Therefore, using a waterproofing membrane is an effective solution for ensuring the safety and functionality of water tanks or reservoirs.

- Q: How does a waterproofing membrane perform in areas with high temperature fluctuations?

- Various environments, including those with high temperature fluctuations, require a waterproofing membrane to act as a protective barrier against moisture infiltration. The performance of the waterproofing membrane in these areas can be influenced by factors such as the material chosen, the installation method, and the specific conditions of the application. To withstand the expansion and contraction that occurs in the substrate during high temperature fluctuations, a high-quality waterproofing membrane must maintain its integrity. It is crucial to consider the material used for the membrane, as certain materials like modified bitumen or thermoplastic olefin (TPO) possess inherent flexibility and durability, enabling them to effectively endure temperature fluctuations. These materials have the capacity to expand and contract without developing cracks or splits, thus ensuring the long-term performance of the waterproofing system. The installation method is also of great importance in guaranteeing the effectiveness of the waterproofing membrane in areas with temperature fluctuations. Proper installation techniques, including appropriate surface preparation, adequate adhesion, and suitable seam sealing, are necessary to establish a continuous and reliable barrier against moisture intrusion. Additionally, the incorporation of expansion joints or movement accommodation details can assist in accommodating thermal movements and preventing stress on the membrane. Maintenance and inspection are essential in identifying any potential issues or damage to the waterproofing membrane caused by temperature fluctuations. Timely repairs or replacements of damaged sections can prevent further deterioration and preserve the functionality of the waterproofing system. To sum up, a well-designed and correctly installed waterproofing membrane can effectively function in areas with high temperature fluctuations. The choice of material, installation techniques, and regular maintenance all play significant roles in ensuring the durability and long-term performance of the waterproofing system in such environments.

- Q: Are waterproofing membranes suitable for bridge abutments?

- Yes, waterproofing membranes are suitable for bridge abutments. Bridge abutments are the structures that support the ends of a bridge, and they are typically exposed to a significant amount of moisture and water. Waterproofing membranes are designed to provide a protective barrier against water and moisture intrusion, making them an ideal solution for bridge abutments. These membranes are typically made from materials such as bitumen, PVC, or EPDM, which are highly resistant to water penetration. Additionally, waterproofing membranes can also provide protection against other factors such as UV rays, chemicals, and temperature fluctuations. By installing waterproofing membranes on bridge abutments, the risk of water damage, deterioration, and corrosion can be significantly reduced, leading to increased durability and longevity of the bridge structure.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Certainly, a waterproofing membrane can be utilized alongside green building practices. In actuality, integrating a waterproofing membrane into the construction of a green building can greatly enhance its overall sustainability and efficiency. One of the fundamental principles of green building practices is to maximize energy efficiency and decrease the environmental impact of a structure. By installing a waterproofing membrane, the building's outer covering can be shielded from moisture intrusion, thereby preventing water damage and potential mold growth. This, in turn, aids in preserving the structural integrity of the building, reducing the necessity for costly repairs and replacements, which can consume resources and generate waste. Moreover, a waterproofing membrane can contribute to improved indoor air quality. By preventing water infiltration, it assists in creating a dry and healthy living or working environment, minimizing the risk of respiratory problems and other health issues associated with dampness. Furthermore, a waterproofing membrane can enhance the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it lessens the potential for heat loss through moisture evaporation, thus reducing the energy required for heating and cooling. This can lead to decreased energy consumption and lower carbon emissions, aligning with the objectives of green building practices. However, it is crucial to select a waterproofing membrane that is environmentally friendly and compliant with green building standards. Seek out membranes that are crafted from recycled or sustainable materials and possess low VOC (volatile organic compound) content. Additionally, consider opting for a membrane that is designed for longevity and durability, as this can further minimize the environmental impact by reducing the need for replacement over time. In conclusion, a waterproofing membrane can be an invaluable addition to any green building endeavor. It serves to safeguard the building envelope, enhance indoor air quality, and improve energy efficiency. By choosing an environmentally friendly membrane, the overall sustainability of the building can be further enhanced.

Send your message to us

PVC Waterproofing Membrane Polyester Scrim Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords