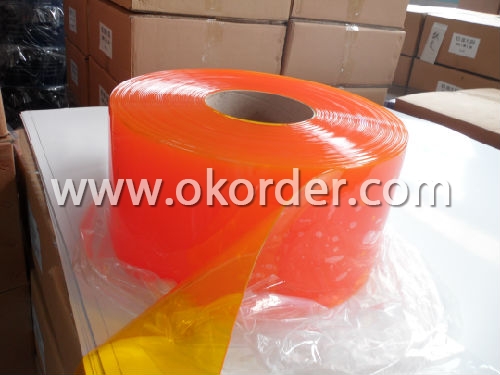

PVC Strip Doors in High Quality

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 sets roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Clear Flexible PVC Strip Curtain For Coldroom

1. the CHEAPEST and the FASTEST solution to divide small or large rooms.

2.Strips: made of transparent or coloured plastic in full or partial overlap and are supported by fixed or sliding metal junctions.

3.can create real partion walls suitable to divide rooms and sheds.

4.a barrier against bugs and birds. they can be installed either in food or in pharmaceutical areas.

5.Suitable for LOW TEMPERATURES: -50 °C to -50 °C is also available.

6.Easy and quick to install and do not require any particular maintenance.

7.Solid or sliding track manufactured in either stainless or galvanized finishes.

8.This product is manufactured to suit the clear open specified by the client.

Applications of Clear Flexible PVC Strip Curtain For Coldroom

PVC flexible strip doors are widely used in the following area:

Door construction, lamellar doors

Trade and industry

Seperation of production and storage sites

Cold stores,cold store depots

Door area screening for cold stire vehicle

Coloured warning strips for industrial doors

As a view protection, also with frosted surfaces

Package& Delivery of Clear Flexible PVC Strip Curtain For Coldroom

Wooden pallet,shirnk film according to custom requires.

Colors of Clear Flexible PVC Strip Curtain For Coldroom

Blue, Green, Orange, White and Yellow.

Other colours are available on request.

- Q: What are the considerations for using recyclable plastic in home appliances?

- There are several key considerations when using recyclable plastic in home appliances. Firstly, the quality and durability of the plastic must be assessed to ensure it can withstand the demands of the appliance's intended use. Additionally, the availability and accessibility of recycling facilities should be considered to ensure proper disposal and recycling at the end of the appliance's lifespan. It is also important to evaluate the environmental impact of the entire lifecycle of the appliance, including the production, use, and disposal stages, to determine if using recyclable plastic is truly beneficial in terms of reducing overall environmental footprint. Lastly, the cost implications of using recyclable plastic, including potential increases in manufacturing costs, should be evaluated to ensure it aligns with the overall affordability and value of the appliance.

- Q: Do plastic home appliances require any specific assembly procedures?

- No, plastic home appliances generally do not require any specific assembly procedures as they are usually designed to be ready to use out of the box.

- Q: Can plastic home appliances be easily controlled remotely?

- Yes, plastic home appliances can be easily controlled remotely with the help of smart technology and internet connectivity. Many plastic appliances such as smart speakers, smart TVs, and smart home hubs are designed to be controlled remotely through smartphone apps or voice commands. Additionally, various remote control devices can be connected to plastic appliances to enable remote operation.

- Q: How does the plastic used in refrigerator doors affect energy efficiency?

- The plastic used in refrigerator doors can have both positive and negative impacts on energy efficiency. On one hand, plastic is a good insulator and can help to reduce heat transfer between the inside and outside of the refrigerator, thus improving energy efficiency. On the other hand, if the plastic is of poor quality or not properly insulated, it can lead to heat leaks and reduce the overall energy efficiency of the refrigerator. Therefore, the type and quality of plastic used in refrigerator doors play a crucial role in determining its impact on energy efficiency.

- Q: Are there any disadvantages to using plastic in home appliances?

- Yes, there are several disadvantages to using plastic in home appliances. Firstly, plastic is not as durable as other materials like metal or glass, making appliances more prone to breakage and wear over time. Additionally, plastic can release harmful chemicals when exposed to heat or certain substances, which can pose health risks. Plastic is also non-biodegradable and contributes to environmental pollution, as it takes hundreds of years to decompose. Lastly, the production of plastic requires fossil fuels, contributing to greenhouse gas emissions and climate change.

- Q: How can plastic parts in toasters and toaster ovens resist warping and deformation from heat exposure?

- Plastic parts in toasters and toaster ovens can resist warping and deformation from heat exposure due to the use of heat-resistant materials such as thermoplastics, which have high melting points and can withstand elevated temperatures. Additionally, these plastic parts are often reinforced with additives like glass fibers or other fillers that further enhance their strength and rigidity. The design and engineering of these parts also play a crucial role, as they are carefully crafted to distribute heat evenly and prevent localized hotspots that could potentially cause warping.

- Q: Can plastic home appliances be used in outdoor environments?

- Plastic home appliances can generally be used in outdoor environments, but it is important to consider the specific appliance and the conditions it will be exposed to. Some plastic appliances may not be designed to withstand extreme temperatures, excessive moisture, or direct sunlight for prolonged periods. Therefore, it's crucial to check the manufacturer's guidelines and ensure the appliance is suitable for outdoor use before exposing it to outdoor conditions.

- Q: Can plastic parts in home appliances be affected by chemical exposure?

- Yes, plastic parts in home appliances can be affected by chemical exposure. Exposure to certain chemicals can cause the plastic to degrade, become brittle, discolor, or even break down. It is important to be cautious and avoid exposing plastic parts to harsh chemicals to maintain the longevity and functionality of home appliances.

- Q: Can plastic home appliances be easily maintained and cleaned by the end user?

- Yes, plastic home appliances can generally be easily maintained and cleaned by the end user. Plastic is a durable material that is resistant to stains and can be wiped clean with a damp cloth. Additionally, most plastic appliances have detachable parts that can be easily cleaned in the sink or dishwasher. However, it is important to follow the manufacturer's instructions for cleaning and maintenance to ensure the longevity of the appliance.

- Q: Can plastic parts in coffee makers resist staining and discoloration over time?

- Yes, plastic parts in coffee makers can resist staining and discoloration over time. Many coffee makers use materials such as polycarbonate or high-density polyethylene that are known for their resistance to staining. Additionally, manufacturers often apply special coatings or finishes to the plastic parts to further enhance their resistance to discoloration. However, it is important to note that regular cleaning and maintenance of the coffee maker can also contribute to preserving the appearance of the plastic parts.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Strip Doors in High Quality

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 sets roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches