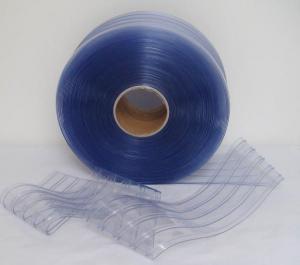

PVC Strip Curtain with Factory-sale Normal Tempt Grade

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls roll

- Supply Capability:

- 10 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Factory Sale Normal Temperature Grade PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Factory Sale Normal Temperature Grade PVC Strip Curtains

(1)Very Light Duty

sed in areas with very light pedestrian traffic or fragile goods, and light industrial doorways.

Light Duty, Pedestrian and pallet trolley access, for wind and dust exclusion areas. Commonly used in food processing industries and for internal wall and doorway separation.

(2)Medium Duty

used in outdoor or indoor conditions where requiring contamination exclusion. Pallet trolleys, light fork lift and pedestrian use.

(3)Heavy Duty

outdoor or indoor conditions requiring significant weather/environmental exclusion and heavy/frequent pedestrian and fork lift traffic

Package& Delivery of Factory Sale Normal Temperature Grade PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Types of Factory Sale Normal Temperature Grade PVC Strip Curtains

Normal Grade PVC strip rolls comes in shape of Smooth and Ribbed,brillantly trandsparent and clear,these are useful for -20℃to +50℃temperature applications.

(1) Smooth PVC strip rolls:

Smooth PVC strips are flat shape,brilliantly transparent and clear,it is available in clear transparent,non viscidity and wide color selections.

(2)Ribbed PVC strip rolls:

the unique rib design of these strips let the rib portion take the impact of truck and forklift traffic.this prevents scratching as well as grease and grime building up ,the unique rib design keeps the strips cleaner,and becomes long lasting.

Please refer to our products page or ask for our CNBM's PRODUCTS GENERAL STANDARDS COMPARISON TABLE

- Q: What are the considerations for using flame-retardant plastics in home appliances?

- There are several considerations when using flame-retardant plastics in home appliances. Firstly, the chosen flame-retardant material should have high thermal stability to withstand the heat generated by the appliance without degrading or releasing toxic fumes. Secondly, it is important to ensure that the flame-retardant additives used do not negatively affect the overall performance or functionality of the appliance. Additionally, the cost of incorporating flame-retardant plastics should be balanced with the potential benefits in terms of fire safety. Lastly, it is crucial to comply with relevant safety standards and regulations to ensure the effectiveness and reliability of the flame-retardant properties in home appliances.

- Q: Can plastic parts in home appliances be affected by exposure to chemicals or solvents?

- Yes, plastic parts in home appliances can be affected by exposure to chemicals or solvents. Chemicals and solvents can potentially react with the plastic material, leading to degradation, discoloration, or even structural damage. It is important to follow manufacturer's guidelines and avoid using harsh chemicals or solvents on plastic parts to ensure their longevity and proper functioning.

- Q: What are the main challenges in recycling plastic from home appliances?

- One of the main challenges in recycling plastic from home appliances is the complexity of the plastic materials used in their construction. Home appliances often contain multiple types of plastic, each with different melting points and chemical compositions, making it difficult to separate and recycle them effectively. Additionally, the presence of other materials like metal or rubber in appliances can further complicate the recycling process. Another challenge is the lack of awareness and proper infrastructure for recycling these specific types of plastic, as many recycling facilities are primarily equipped to handle more common plastics like bottles and containers. Therefore, developing specialized recycling techniques and increasing awareness among consumers and recycling facilities are crucial steps to overcome these challenges.

- Q: What are the main factors that determine the scratch resistance of plastic parts in home appliances?

- The main factors that determine the scratch resistance of plastic parts in home appliances are the type and quality of the plastic material used, the surface treatment or coating applied, and the external forces or conditions the appliance is exposed to during use and handling.

- Q: How do plastic home appliances compare in terms of weight?

- Plastic home appliances generally tend to be lighter in weight compared to their counterparts made from other materials such as metal or glass.

- Q: How does plastic contribute to the longevity of home appliances?

- Plastic contributes to the longevity of home appliances by providing durability, resistance to corrosion and moisture, and insulation properties that protect internal components. Additionally, plastic parts can be molded into intricate shapes, enabling the design of complex and efficient appliances.

- Q: Can home appliance plastics be safely disposed of?

- Yes, home appliance plastics can be safely disposed of through various methods such as recycling, proper waste management, and utilizing specialized disposal facilities.

- Q: How can plastic parts in ovens and stoves resist discoloration and fading due to heat exposure?

- Plastic parts in ovens and stoves can resist discoloration and fading due to heat exposure through the use of heat-resistant materials and additives. These materials are specifically designed to withstand high temperatures and prevent color fading. Additionally, manufacturers may incorporate UV stabilizers into the plastic formulation to protect against discoloration caused by sunlight or other sources of UV radiation. Regular testing and quality control measures are also implemented to ensure the durability and longevity of these plastic parts under extreme heat conditions.

- Q: How does the chemical stability of plastic affect the longevity of home appliances?

- The chemical stability of plastic directly impacts the longevity of home appliances. Plastic materials that possess high chemical stability are less prone to degradation and deterioration over time. This means they are more resistant to chemical reactions, environmental factors such as heat and moisture, and the effects of aging. Consequently, appliances made with chemically stable plastics are more likely to have a longer lifespan, as they can withstand the stresses and strains of daily use without significant deterioration.

- Q: How are plastic parts in washing machines protected from water leakage?

- Plastic parts in washing machines are protected from water leakage through the use of seals, gaskets, and waterproof coatings. These components are designed to create a tight and secure barrier, preventing water from seeping into areas where it shouldn't be. Additionally, modern washing machines often feature a water-tight housing or casing to further protect the internal plastic parts from any potential water leaks.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Strip Curtain with Factory-sale Normal Tempt Grade

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls roll

- Supply Capability:

- 10 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches