Replacement Upvc Door Handles

Replacement Upvc Door Handles Related Searches

Shower Handle Replacement Parts Replacement Parts For Screen Doors Replacement Window Sash Locks Security Screen Door Handles Door Handles Nz Double Glazed Door Handles French Door Replacement Parts Industrial Door Handles And Locks Replacement Shower Parts Led Headlamp Replacement Shower Valve Parts Replacement Replacing Front Bumper Replace Front Bumper Upvc Decorative Mouldings Hudson Sprayer Replacement Wand Replacement Plumbing Parts Tub Valve Replacement Led Headlight Bulb Replacement Fireplace Inserts Replacement Parts Latch Handle Door Set Pvc Chairs For Sale Glass Shower Door Hooks Exterior Door Hooks Led Replacement Headlight Bulb Decorative Interior Doors T8 Led Replacement Lamps Front Entry Doors External Doors Pvc Panel Door Pvc CeilingsReplacement Upvc Door Handles Supplier & Manufacturer from China

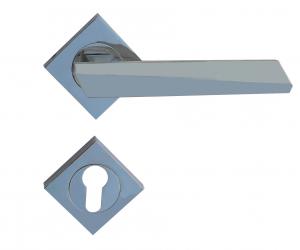

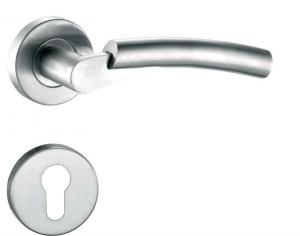

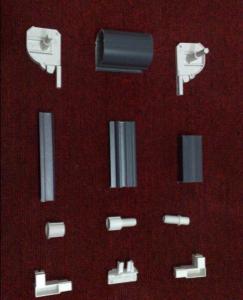

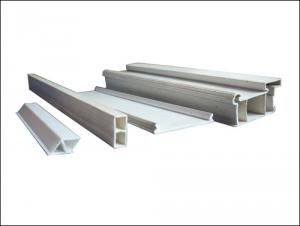

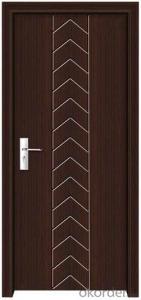

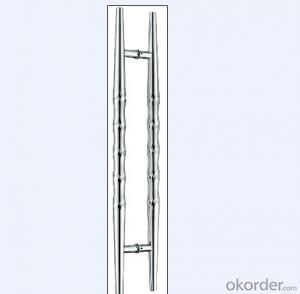

Replacement UPVC Door Handles are essential components for maintaining the functionality and security of UPVC doors. These handles come in various designs and finishes to suit different door styles and preferences. They are designed to provide a sturdy grip and ensure smooth operation, making them an indispensable part of any UPVC door system.The application and usage scenarios for Replacement UPVC Door Handles are vast, as they are commonly used in residential, commercial, and industrial settings. These handles are ideal for replacing worn-out or damaged door handles, as well as for upgrading the aesthetics and security of existing doors. They can be easily installed by homeowners or professionals, making them a popular choice for those looking to improve the appearance and functionality of their doors without incurring significant costs.

Okorder.com is a leading wholesale supplier of Replacement UPVC Door Handles, offering a wide range of options to cater to various needs and preferences. With a large inventory, Okorder.com ensures that customers have access to high-quality door handles at competitive prices. Their extensive selection and commitment to customer satisfaction make them a reliable source for all Replacement UPVC Door Handles requirements.

Hot Products