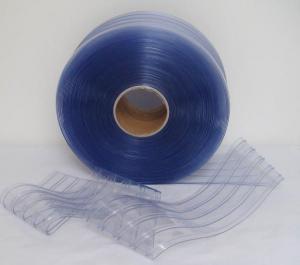

PVC Strip Doors in Best Selling

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 sets roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Factory Sale PVC Strip Doors

1. the CHEAPEST and the FASTEST solution to divide small or large rooms.

2.Strips: made of transparent or coloured plastic in full or partial overlap and are supported by fixed or sliding metal junctions.

3.can create real partion walls suitable to divide rooms and sheds.

4.a barrier against bugs and birds. they can be installed either in food or in pharmaceutical areas.

5.Suitable for LOW TEMPERATURES: -50 °C to -50 °C is also available.

6.Easy and quick to install and do not require any particular maintenance.

7.Solid or sliding track manufactured in either stainless or galvanized finishes.

8.This product is manufactured to suit the clear open specified by the client.

Applications of Factory Sale PVC Strip Doors

PVC flexible strip doors are widely used in the following area:

Door construction, lamellar doors

Trade and industry

Seperation of production and storage sites

Cold stores,cold store depots

Door area screening for cold stire vehicle

Coloured warning strips for industrial doors

As a view protection, also with frosted surfaces

Package& Delivery of Factory Sale PVC Strip Doors

Wooden pallet,shirnk film according to custom requires.

Colors of Factory Sale PVC Strip Doors

Blue, Green, Orange, White and Yellow.

Other colours are available on request.

- Q: How long does plastic used in home appliances typically last?

- The lifespan of plastic used in home appliances can vary depending on the quality of the plastic, the specific appliance, and how it is used and maintained. However, on average, plastic components in home appliances can last anywhere from 5 to 15 years.

- Q: What are the main challenges in recycling plastic from home appliances?

- One of the main challenges in recycling plastic from home appliances is the complexity of their composition. Home appliances often contain a mix of different types of plastics, metals, and other materials, which makes it difficult to separate and recycle the plastic components. Additionally, the size and shape of the plastic parts can also pose challenges, as they may be too large or have intricate designs that make recycling more labor-intensive. Another significant challenge is the lack of awareness and infrastructure for proper disposal and recycling of these appliances, leading to a significant amount of plastic waste ending up in landfills instead of being recycled.

- Q: Are there any health concerns associated with plastic in home appliances?

- Yes, there are potential health concerns associated with plastic in home appliances. Plastics can contain harmful chemicals like phthalates and bisphenol A (BPA), which can leach into food or water when heated or stored for long periods. These chemicals have been linked to various health issues, including hormonal disruptions, reproductive problems, and certain cancers. It is advisable to choose appliances made from BPA-free and food-grade plastics or opt for alternatives like stainless steel or glass to minimize potential health risks.

- Q: How do home appliance plastics impact the overall lifespan and durability of the appliance?

- Home appliance plastics play a crucial role in enhancing the overall lifespan and durability of the appliance. These plastics are chosen for their strength, flexibility, and resistance to heat, moisture, and chemicals. They protect the internal components, prevent corrosion, and provide insulation. Additionally, their lightweight nature allows for ease of use and transportation. By ensuring the longevity and reliability of the appliance, home appliance plastics contribute significantly to its overall lifespan and durability.

- Q: How to remove the formaldehyde taste of plastic products?

- Decoration deodorant removes Home Furnishing exposed part of the formaldehyde, furniture plate junction, where a larger amount of glue, will produce harmful gas free; activated carbon sealing plastic packaging is opened, the environmental protection non-woven bag bag into the room, come up with new furniture, cabinets and other needs of deodorizing and detoxification, purifying the air spaces then, activated carbon has a strong adsorption function of formaldehyde, benzene, toluene, xylene, ethanol, gasoline, kerosene, styrene, vinyl chloride and other harmful substances, toxic molecules meet the activated carbon surface, will be caught.

- Q: Can plastic parts in home appliances be affected by exposure to magnetic fields?

- Yes, plastic parts in home appliances can be affected by exposure to magnetic fields. Magnetic fields can induce electric currents in the plastic, which can lead to heat generation and potentially cause damage to the plastic components. Additionally, magnetic fields can also cause the plastic parts to become magnetized, affecting their functionality or performance.

- Q: How long do plastic components in home appliances typically last?

- The lifespan of plastic components in home appliances can vary depending on several factors such as usage, maintenance, and quality of materials. However, on average, plastic components in home appliances tend to last anywhere from 5 to 15 years.

- Q: How does the use of plastic in home appliances impact the overall cost of production?

- The use of plastic in home appliances generally reduces the overall cost of production. Plastic is a low-cost material compared to alternatives like metal or glass, making it a popular choice for manufacturers. Plastic is lightweight, easy to mold, and requires less energy to process, resulting in lower production costs. Moreover, plastic components can be mass-produced efficiently, allowing for economies of scale. However, the cost of plastic can fluctuate due to factors like oil prices and environmental regulations, which can impact the overall cost of producing home appliances.

- Q: What are the considerations for using dishwasher-safe plastic in home appliances?

- When using dishwasher-safe plastic in home appliances, there are a few considerations to keep in mind. Firstly, it is important to ensure that the plastic is indeed labeled as dishwasher-safe, as not all types of plastic can withstand the high temperatures and harsh detergents used in dishwashers. Secondly, it is crucial to follow the manufacturer's instructions regarding temperature limits and cycle options to prevent damage to the plastic. Additionally, it is advisable to avoid using abrasive scrubbers or harsh chemicals that may degrade the plastic over time. Regular inspection of the plastic for any signs of wear or damage is also recommended to ensure its continued safety and effectiveness.

- Q: Are plastic home appliances resistant to UV radiation or sun damage?

- No, plastic home appliances are not typically resistant to UV radiation or sun damage.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1991 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | 40.00% Southeast Asia 15.00% Mid East 10.00% South America 5.00% Southern Europe 5.00% Northern Europe 5.00% Western Europe 5.00% Oceania 5.00% Africa 5.00% Eastern Europe 5.00% North America |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Strip Doors in Best Selling

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 sets roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords