High Quality Suspended PVC Ceiling Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (PVC Ceiling ) Description

High Quality Pvc Ceiling Strips , High quality ceiling products supplier!

1. Aluminum Ceiling Tiles & Planks

2. Strip Linear Ceiling

3. Grille Ceiling

4. Baffle & screen ceiling

5. Wall Panel

6. custom design products are wellcomed

2,Main Features of the (PVC Ceiling )

Main introduction of PVC Ceiling Panels

1.Thickness:5-12MM

2.Width:100-300MM

3.Length:It depends,like 5.8M,5.95M matching with the size of containers.

4.Type: Flat or with a groove in the middle of panels.

5.Contents of PVC panels: normal & popular PVC percentage is 40%, 45%, 50%, 55% or 60%, balance is calcium carbide or other carbonate.

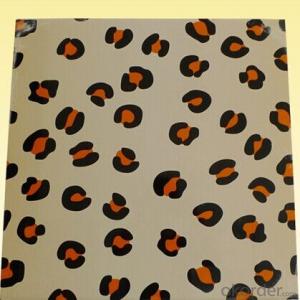

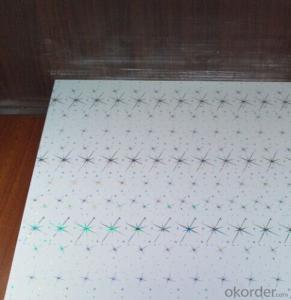

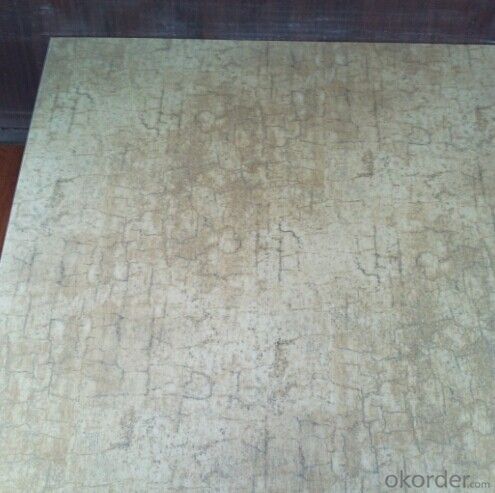

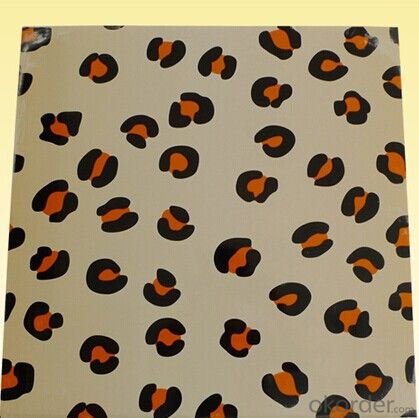

6.Surface treatment:

1)Normal oil printing.

2)Hot stamping.

3)Thermal transferring print

4)Laminated print

7.Surface finishing effect: White / Glossy / High glossy / Gleam etc.

8.Applications:Home kitchen,bathroom,indoor,hotels,hospitals,commercial buildings,meeting room,schools etc

9..Advantage:

1)Economic,Durable.

2)Light in weight and easy to install / assemble with smooth surface,without gap while fixed together.

Available size specifications for customer's checking:

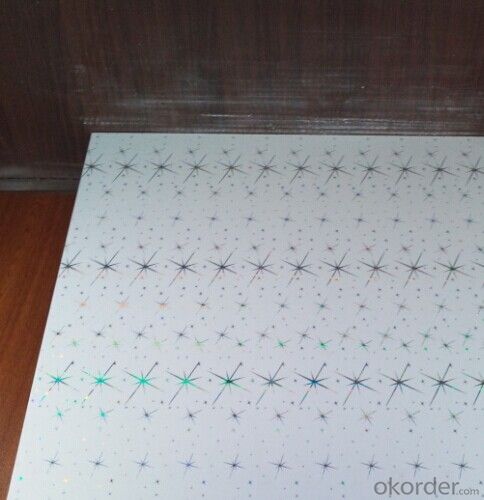

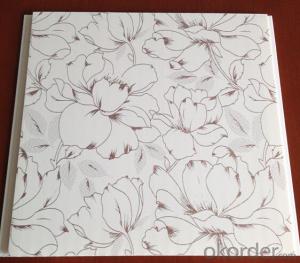

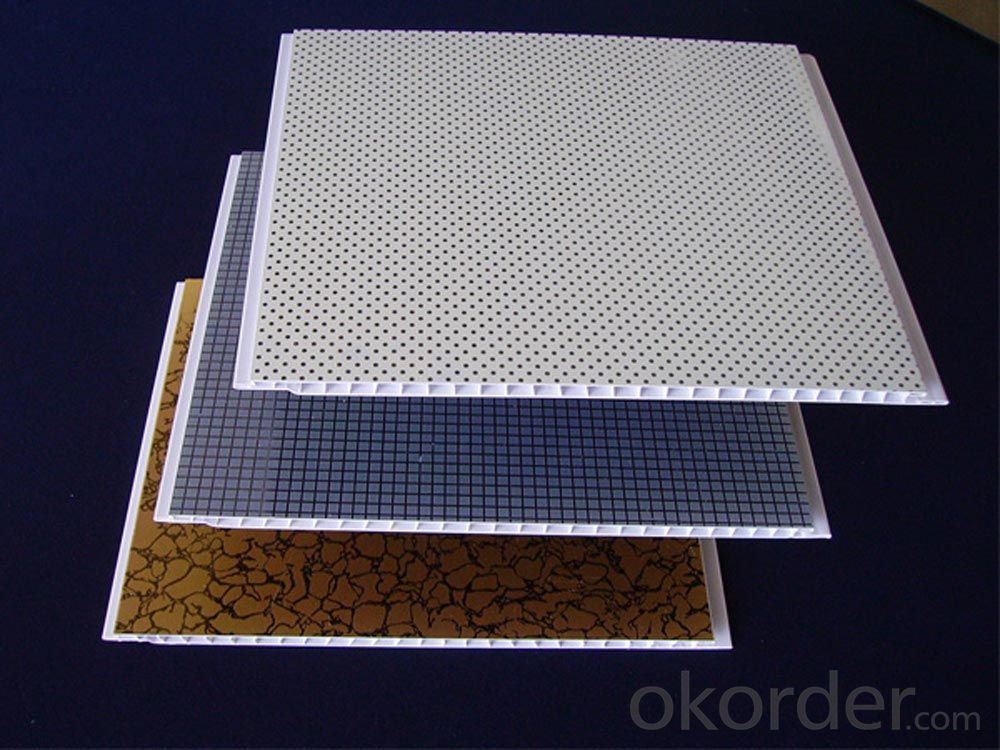

3,(PVC Ceiling ) Images

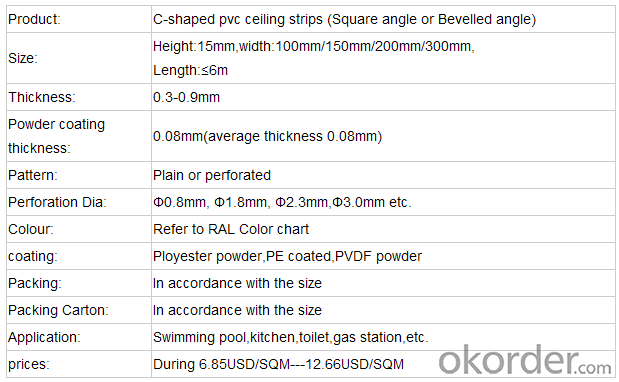

4,(PVC Ceiling ) Specification

5,FAQ of (PVC Ceiling )

1)Normal oil printing.

2)Hot stamping.

3)Thermal transferring print

4)Laminated print

7.Surface finishing effect: White / Glossy / High glossy / Gleam etc.

8.Applications:Home kitchen,bathroom,indoor,hotels,hospitals,commercial buildings,meeting room,schools etc

- Q: Hard PVC transparent board can do shower door?

- Personally think that can not

- Q: Pvc board density

- Commonly used plastic types are: ① polyvinyl chloride (PVC) It is the largest plastic used in the building. Hard PVC density of 1.38 ~ 1.43g / cm3, high mechanical strength, chemical stability, the use of temperature range is generally between -15 ~ +55 ℃, suitable for the manufacture of plastic doors and windows, pipes, troughs and so on. ② Polyethylene (PE) Polyethylene plastic in the building is mainly used for water supply and drainage, sanitary ware. ③ polypropylene (PP) The density of polypropylene is the smallest in all plastics, about 0.90. Polypropylene is often used to produce pipe, sanitary ware and other construction products. ④ polystyrene (PS) Polystyrene is a colorless, transparent glass-like plastic. Polystyrene is mainly used in the construction of foam insulation materials, light transmission materials and other products. ⑤ ABS plastic ABS plastic is modified polystyrene plastic, acrylic (A), butadiene (B) and styrene (S) based on the three components. ABS plastic can be made of pressure pattern of plastic decorative panels and so on. ? This answer is recommended by science education class Shang Shangxiu

- Q: Why do some people tell me when there is a lot of scratches on the color of the polished surface.

- PVC board density is higher, the general paint or paint is not easy to penetrate the surface, if the brush, then there will be leakage of the phenomenon, I suggest you use the spray will be better!

- Q: How to buy pvc floor?

- Pvc floor is made of PVC as raw material, this material is non-toxic, no formaldehyde, so there will be no smell, with realistic imitation wood, carpet pattern, stone pattern and other patterns. We can from the sense of smell, touch, vision, hearing simple to determine whether the floor is qualified One: by the sense of smell. In the selection of the floor, with the nose smell, the floor if there is irritating smell distributed, the floor is likely to contain formaldehyde, or formaldehyde content exceeded. Formaldehyde can damage the body's body and have a long release period. Two: by touch. Hand to feel the flexibility of the floor, or feet to feel the floor of the comfort and smoothness. Floor trampling uncomfortable, not smooth, non-slip, are inferior PVC plastic floor. Three: by vision. Floor color is not pure, pattern, pattern is not clear, irregular, the surrounding floor or surface damage and scratches and so can determine the poor quality of the floor. Four: by hearing. Good PVC plastic flooring has a good sound insulation, customers in the selection of the floor when you can try to move around to determine the PVC plastic floor sound insulation effect, sound insulation is poor, are inferior flooring.

- Q: Ordinary pvc board can heat moisture it?

- PVC board for the family to choose the economy The most common and cheapest ceiling material. It's PVC as raw material, light weight, waterproof, moisture, moth. As a result of the production process to add a flame retardant material, the use of safety. PVC board a variety of types of colors and patterns, imitation mostly plains, but also patterns, imitation marble pattern. Honeycomb network structure, its cross-section, both sides of the mouth and the shape of the mouth. Such materials should be noted that the choice of surface should be free of cracks or scratches. I should be straight, every mouth is smooth, there is no ups and downs and the local phenomenon of the height difference. The sheet can be bent, elastic, and the hand is percussed with a crisp sound of the surface without sinking a certain amount of pressure. Its shortcomings are poor resistance to high temperature performance, warm environment for a long time easy to deformation.

- Q: PVC soft board product description

- Hardness PVC board: product quality first-class, the color is generally gray and white, can also be produced according to customer needs PVC color hard board, its bright colors, nice, the quality of the implementation of GB / T4454-1996, with good chemical stability, Corrosion resistance, hardness, high strength, high strength, anti-ultraviolet (anti-aging), fire-retardant (with self-extinguishing), reliable insulation, smooth surface smooth, non-absorbent, no deformation, easy processing and so on. The product is excellent thermoforming material, can replace part of the stainless steel and other corrosion-resistant synthetic materials, is widely used in chemical, oil, electroplating, water purification equipment, environmental protection equipment, mining, medicine, electronics, communications and decoration industries The Product thickness: 0.8-30mm Product width: 1300mm 1500 mm Length: According to customer needs production.

- Q: PVC board inkjet and PVC board photo which effect is good

- Direct spray on the pvc board is used uv flat panel printing process, Pvc board photo you should refer to the adhesive or car stickers directly mounted on the pvc board. The difference between the two processes is very large, the price gap is also great Uv flat printing is in the pvc direct injection, because uv is the original imported ink to play, waterproof, sunscreen, color lasting .. and a sense of bumps .. good texture Photo is mounted up, not lasting, especially domestic use are on behalf of the ink

- Q: Is the test board with high temperature?

- Mainly to see where you are talking about where the PVC board, is not PVC board, normal: PVC plasticization temperature above 150 degrees, as softening temperature should be at 120 degrees will become soft. Naoshi not very good, if it is corrosive, I can certainly not use this board!

- Q: Can I use PVC flooring on a factory floor?

- Factory workshop can be used. PVC flooring is a very popular in the world today, a new type of lightweight ground decoration materials, also known as "light body material." Is a popular in Europe and the United States and Asia, Japan and South Korea's popular products, popular in foreign countries, from the early 80s began to enter the Chinese market, so far in the domestic large and medium-sized cities have been generally recognized, the use of a wide range, such as family, Schools, office buildings, factories, public places, supermarkets, commercial, sports venues and other places. "PVC floor" refers to the use of PVC material produced by the floor. Specifically, polyvinyl chloride and its copolymer resin as the main raw material, adding filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet on the substrate, the coating process or by rolling, extrusion or extrusion Craft production.

- Q: PVC pattern on the board is how to spray up, PVC plate printing machine manufacturers

- PVC pattern on the board is sprayed through the uv printer. Proceed as follows: 1, computer photoprint software to draw a good pattern; 2, print output software set a good white ink, ink and ink volume; 3, click to start, then the device automatically printed. PVC board printing machine manufacturers concentrated in the Hangzhou area, if the distance from the near, you can go directly to study.

Send your message to us

High Quality Suspended PVC Ceiling Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords